Product Description

First of all, it does not need to provide an additional compressed air source. This feature not only reduces the dependence on external air sources, but also reduces the complexity of equipment installation and operation, saving costs and space for users.

Secondly, the plug-and-play feature makes the use of EVS extremely convenient. Without the tedious installation and debugging process, it can be quickly put into actual operations, greatly improving work efficiency. At the same time, the programmable control function gives it a high degree of flexibility and intelligence, and can be personalized and adjusted according to different operation requirements.

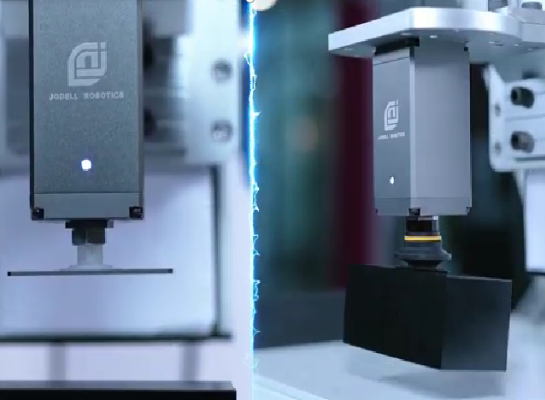

In addition, EVS can be connected to the end connector of the robot arm, achieving perfect coordination with the robot arm and efficiently absorbing the load. This connection method makes it perform well in scenarios such as palletizing and handling, providing strong support for automated production in these fields.

Product parameters

| Vacuum degree | 10%-60% |

| Maximum flow | 2.5L/min |

| Body weight | 0.3 Kg |

| Maximum recommended load | 1Kg |

| Fastest adsorption time | 0.1s |

| Fastest release time | 0.1s |

| Degree of protection | IP40 |

| Service environment | 0-40°℃,85% RH以下 |

| Operating noise | 70dB |

| Rated voltage | DC 24±10%V |

| Rated current | 0.13 A |

| Peak current | 0.3A |

| Compliance with international standards | CE、RoHS |

| Communication | Modbus RTU(RS485) |

| protocol | DigitalI/O |

Technological Innovation

We have developed high-precision vacuum sensors and advanced control systems that can monitor and accurately control the vacuum level inside the actuator in real time. By adjusting the working state of the vacuum pump in real time, we ensure that the vacuum level is always within the set range, thereby improving the adsorption stability and reliability of the actuator. We have realized programmable control, which can be personalized according to different work tasks and load requirements, improving production efficiency and quality.

Product Display

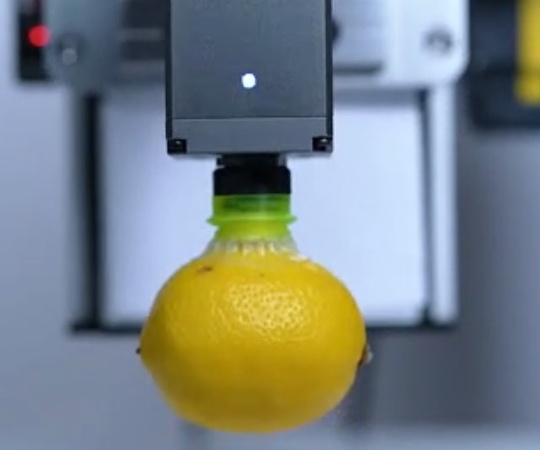

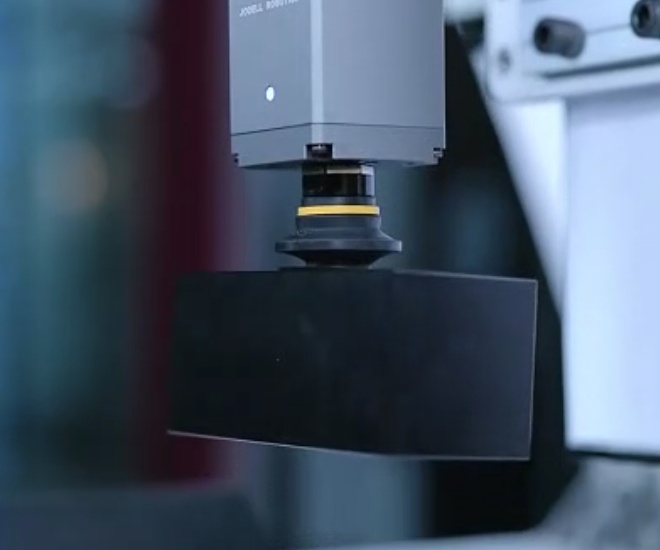

A vacuum actuator is a device that uses the principle of vacuum adsorption to grasp objects. When it is used with different chucks, its application range can be greatly expanded. There are many types of chucks, each with its own unique design purpose and applicable scenarios.

On an automated production line, vacuum actuators with different chucks can be flexibly switched according to the type of product being produced. For example, when it is necessary to carry a housing panel (flat part), a flat suction cup chuck can be used.

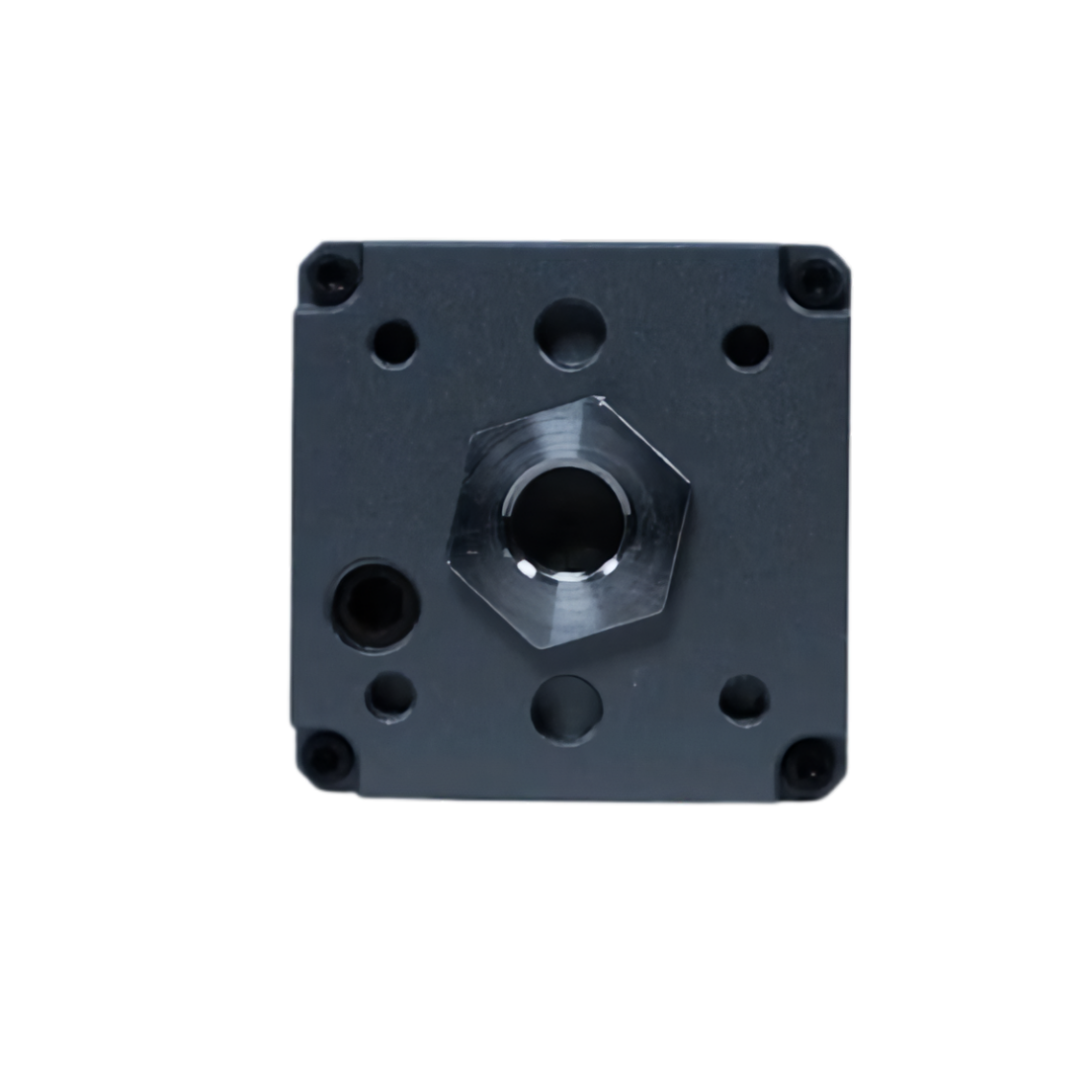

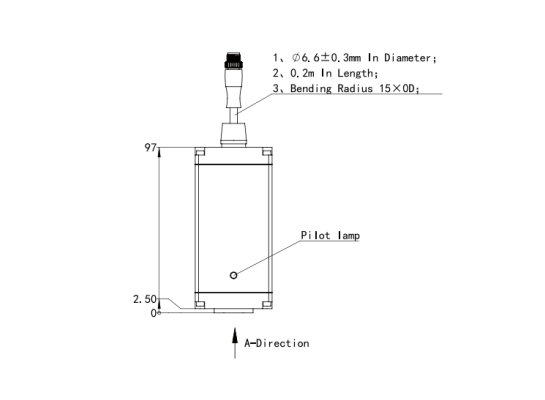

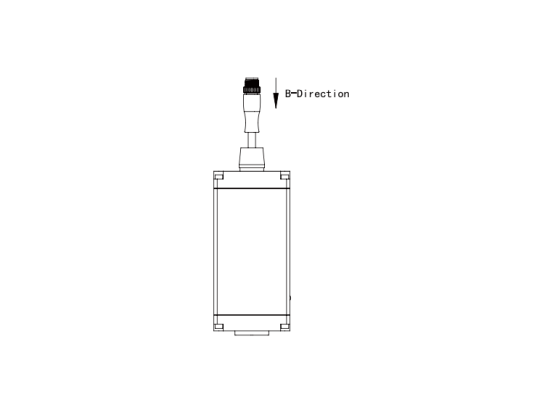

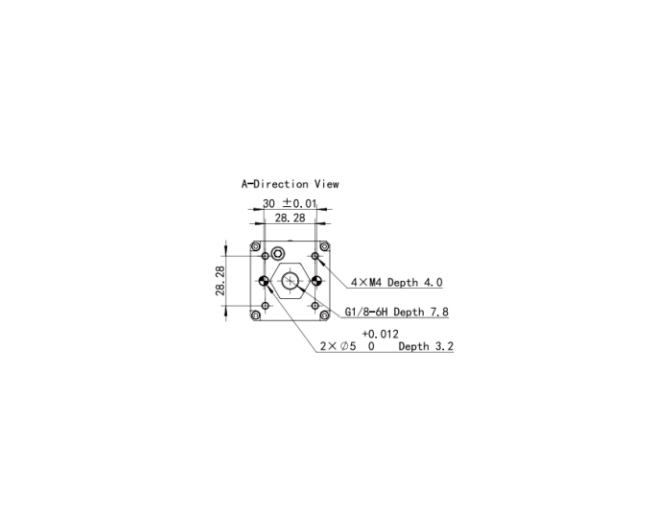

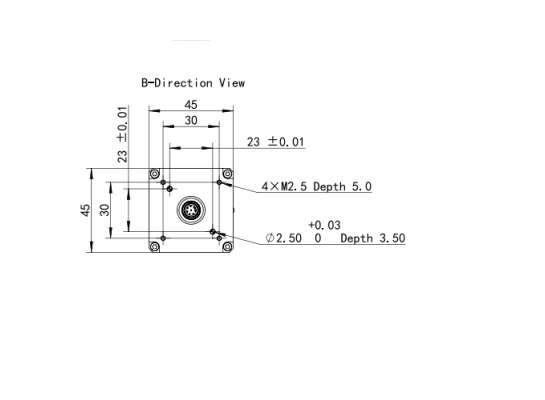

Size & Interface

Application Cases

In the process of mobile phone manufacturing, electric vacuum actuators can be used to adsorb mobile phone screens, batteries, back covers and other components for precise assembly and handling. For example, in the process of bonding the screen to the body, the electric vacuum actuator can accurately adsorb and position the screen to ensure accuracy and stability.