Product Description

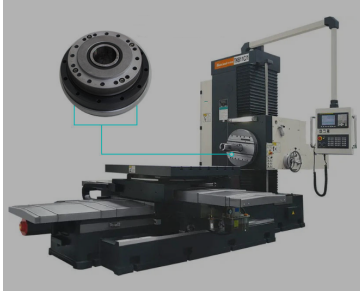

Harmonic reducer is a new type of reduction device, mainly composed of three basic components: wave generator, flexible gear (flexwheel), and rigid gear (rigid wheel). Harmonic reducer is widely used in industrial robots, CNC machine tools, aerospace, medical equipment, automated production lines and other fields. In the field of robotics, it can achieve high-precision position control to ensure that the robot's end effector can accurately reach the predetermined position and perform delicate operations, such as assembling tiny parts and welding electronic products. Although it is small in size, it can provide a large torque in a limited space to meet the power requirements of the robot in situations such as carrying heavy objects and performing complex processing tasks.

Product parameters

| Reduction ratio | 30 | 50 | 80 | 100 | 120 |

| Input rated torque at 2000r/min | 16.2Nm | 27Nm | 76.8Nm | 96Nm | 115.66Nm |

| Allowable peak torque at start and stop | 41.4Nm | 69Nm | 88Nm | 110Nm | 132.53Nm |

| The max. allowable torque of the average load | 22.8Nm | 38Nm | 60Nm | 75Nm | 90.36Nm |

| Backlash | ≤20Arcsec | ≤20Arcsec | ≤10Arcsec | ≤10Arcsec | ≤10Arcsec |

| Maximum input speed allowed | 5600rpm | ||||

| Allowable average inputspeed | 3500rpm | ||||

| Rotational inertia(1/4GD) | 0.282(lx104 kgm²)0.288(Jx105kfgms²) | ||||

Technological Innovation

1.Materials

Ultra-fine ADI material

We use ultra-fine and dense ductile iron continuous-cast hollow profiles and austemperate them to obtain ultra-fine and dense ADI materials.

Features: 1. Self-lubricating 2. Low temperature rise 3. Shock absorption and noise reduction 4. Wide service temperature range 5. Long life

2. Ultra-precision heat treatment process

We have many years of technical experience in material heat treatment processes.

Find the changing rules of the balance point between the two factors of hardness and toughness that affect fatigue strength due to harmonics

A perfect heat treatment process is developed based on the stress accumulation after processing and the stress dissipation before processing.

and fully put into mass production

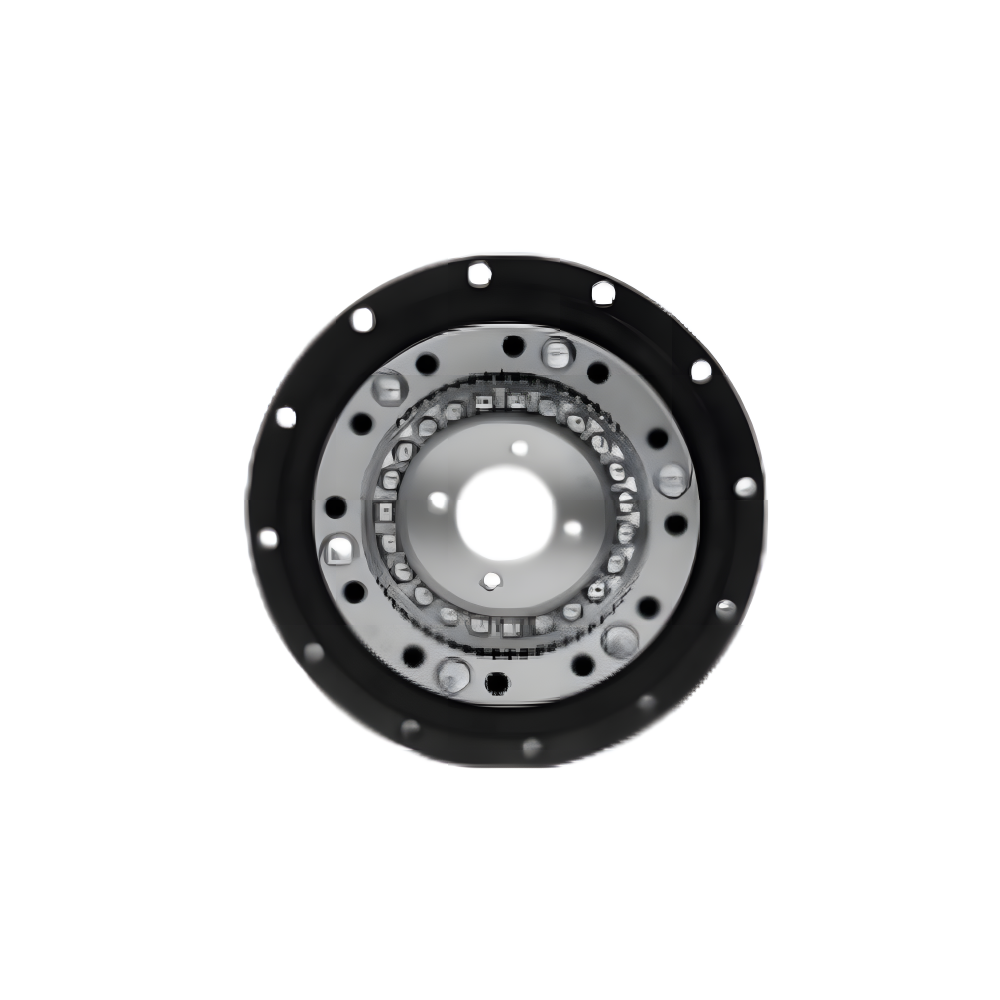

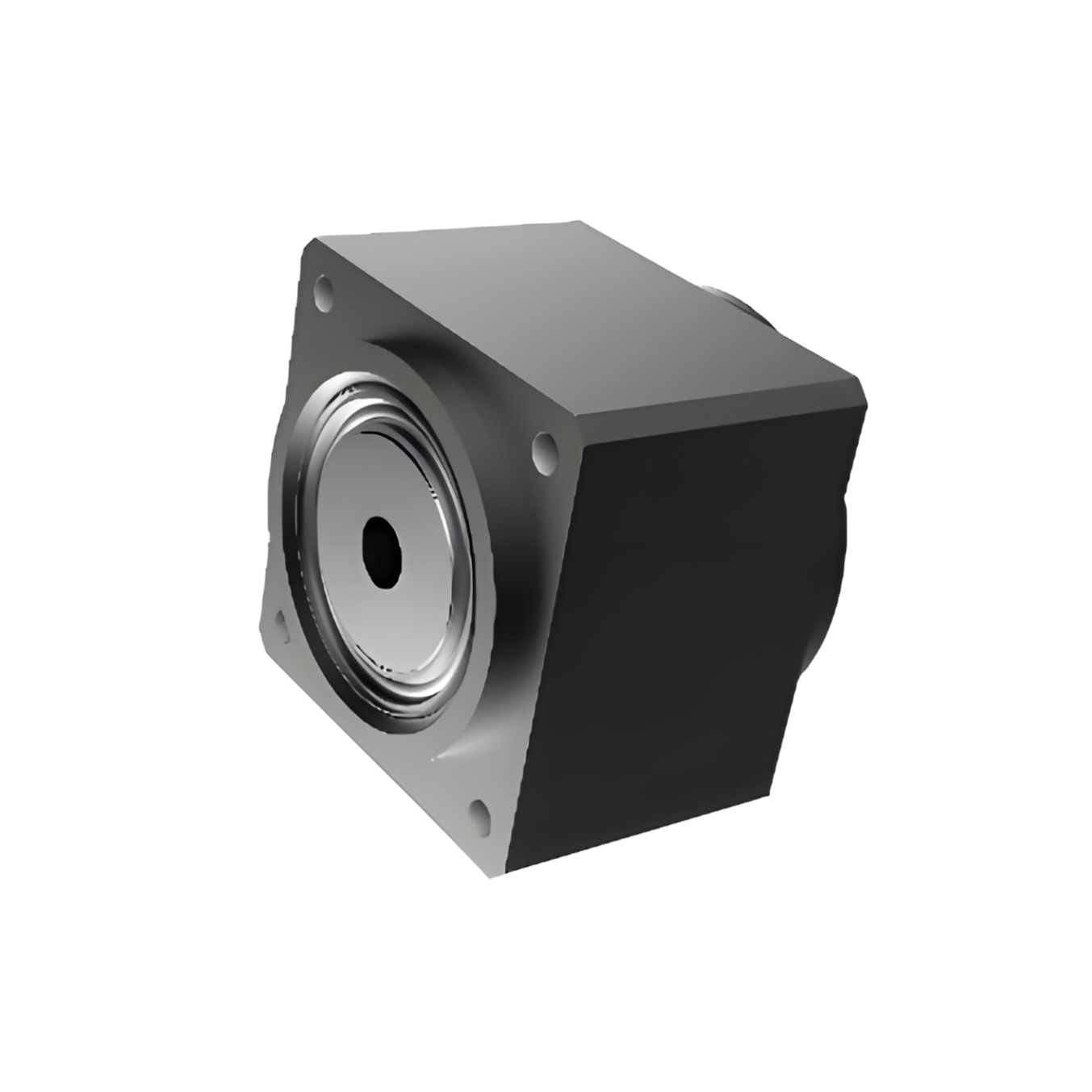

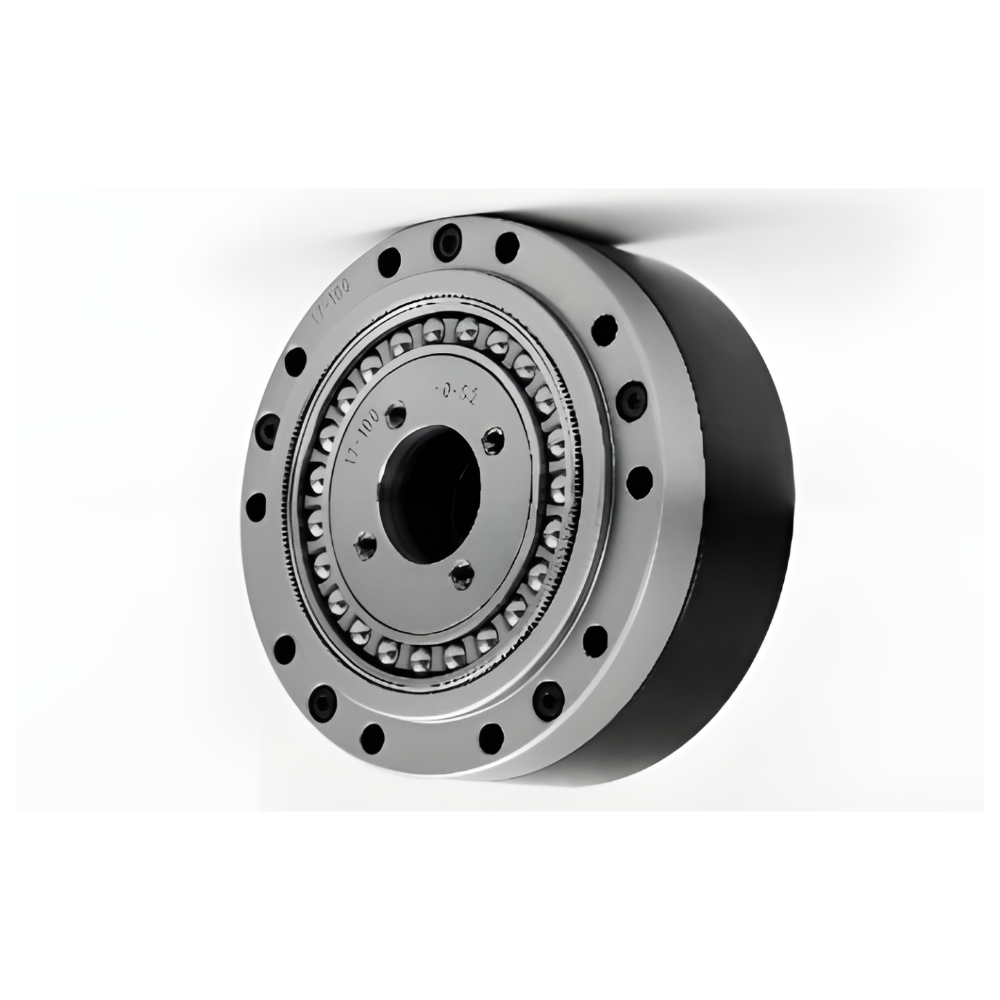

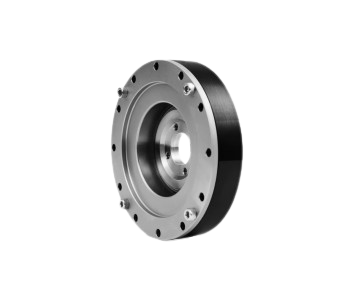

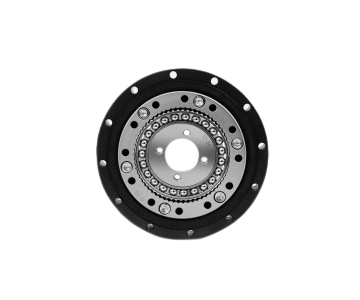

Product Display

In the field of processing technology, we have independently developed a series of high-precision and high-efficiency processing equipment and process routes. From precision forging, CNC cutting to special processing, every link strictly controls the processing accuracy and quality, realizing the transformation and upgrading from traditional processing mode to intelligent and digital processing and manufacturing.

To improve the performance of components, we use special heat treatment processes, surface strengthening technology and microstructure control methods after precision machining to effectively improve the hardness, fatigue strength and dimensional stability of components, ensuring their reliable performance and durability during long-term, high-load harmonic transmission.

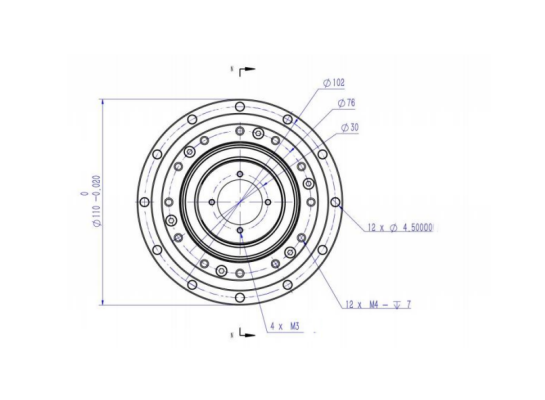

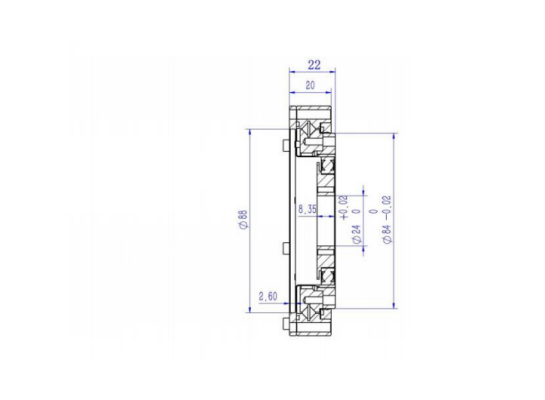

Size & Interface

Application Cases

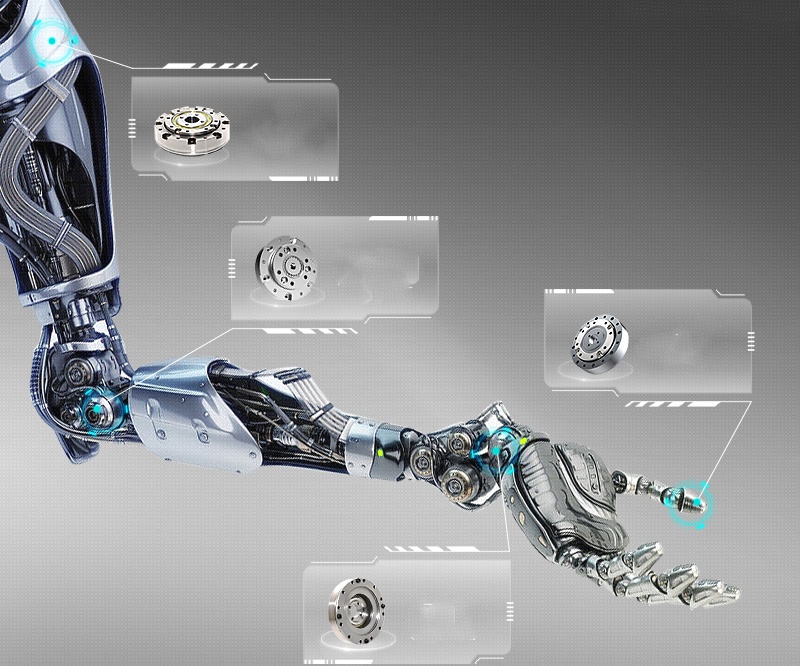

The harmonic reducer is small in size and light in weight, and can be installed in the small space of the robot hand to provide precise power transmission and motion control for the hand joints, allowing the robot hand to achieve flexible movements. In addition, the low vibration and low noise characteristics of the harmonic reducer also help reduce vibration and noise during hand joint movements, improving the operational stability and quietness of the robot. The limbs of humanoid robots need to complete various complex and delicate movements, such as grabbing objects, walking, climbing, etc. The harmonic reducer has high transmission accuracy, which can ensure that the robot's limb joints accurately reach the predetermined position and achieve high-precision motion control.