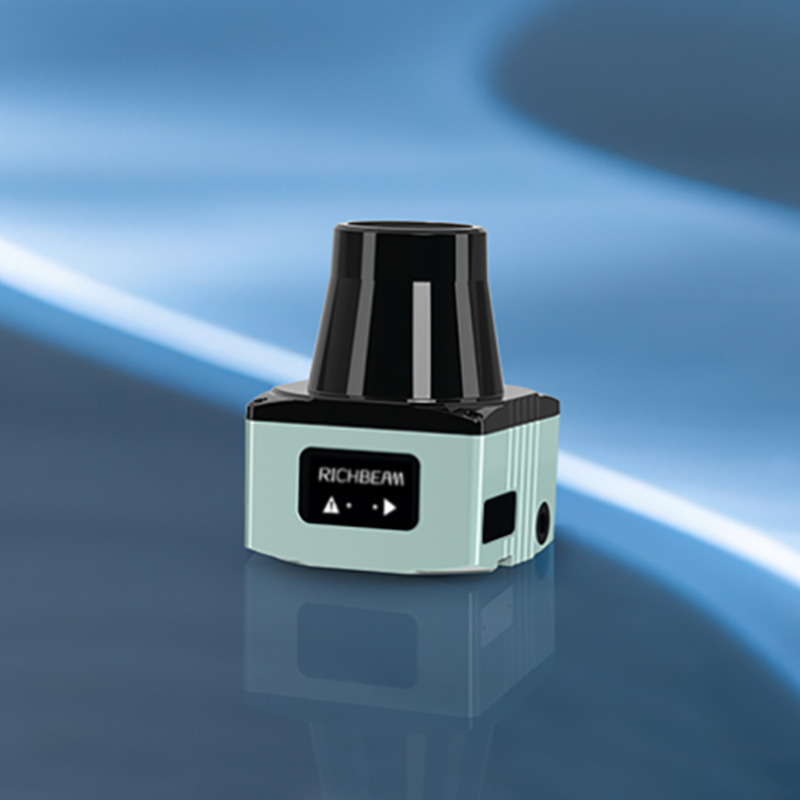

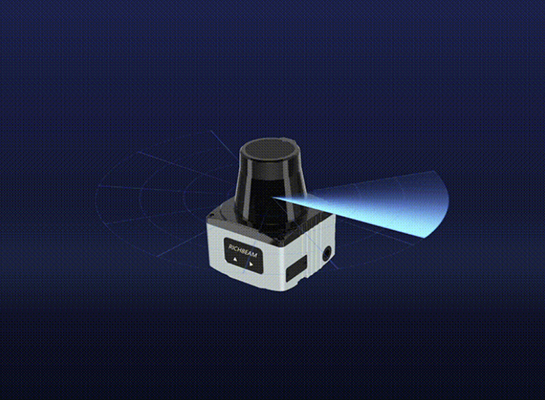

产品描述

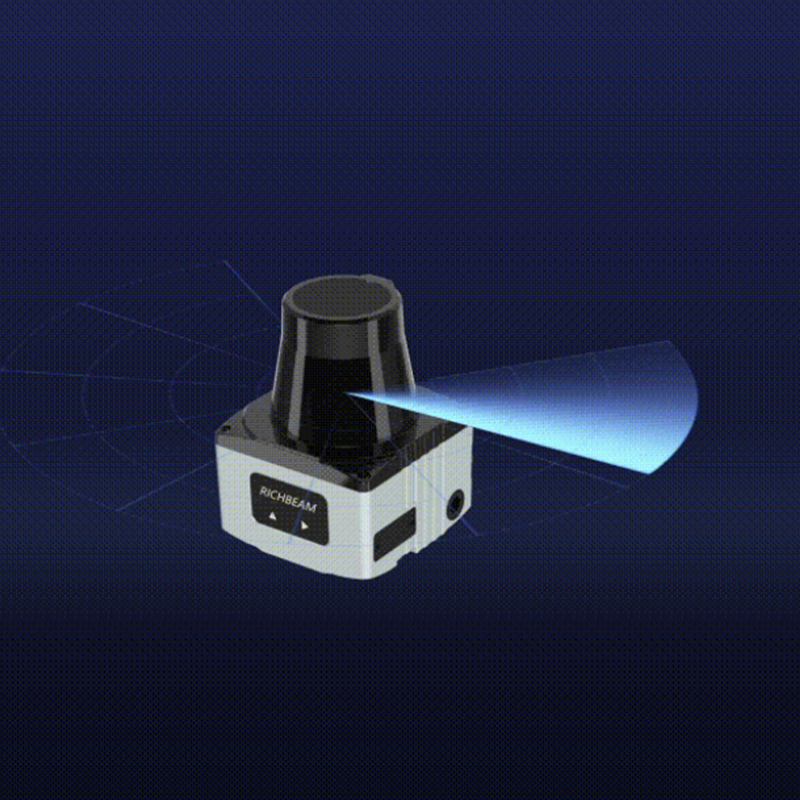

作为锐驰智光旗舰产品,LakiBeam系列兼具性能、成本和可靠性,点云抖动小,质量高,能够捕捉到更多环境细节,同时适配所有主流算法,一度成为锐驰智光复购率最高的单线激光雷达产品。近距离0盲区探测:LakiBeam系列不仅可以实现最大50m的远距离探测,0距离下点云表现依旧优异,对于近距离障碍物,能够以最快速度做出检测,确保机器可以安全运行。

产品参数

| 激光雷达型号 | LakiBeam1 | LakiBeam1L | LakiBeam1S | |

|---|---|---|---|---|

| 测距原理 | 脉冲TOF | |||

| 扫描原理 | 机械旋转 | |||

| 测量精度 | ±2cm | |||

| 水平视场角 | 270° | |||

| 探测距离 | ≥25m@70%反射率 | ≥40m@70%反射率 | ≥15m@70%反射率 | |

| ≥15m@10%反射率 | ≥20m@10%反射率 | ≥10m@10%反射率 | ||

| 数据采样率 | 36KHz;28.8KHz | 43.2kHz | 18kHz(10Hz); 14.4kHz(20Hz) | |

| 36KHz;43.2KHz | ||||

| 水平角分辨率 | 0.1°;0.25°; | 10Hz/0.1°; 25Hz/0.25° | 0.2°(10Hz); | |

| 及对应旋转频率 | 0.25°;0.25° | 20Hz/0.25°;30Hz/0.25° | 0.5° (20Hz) | |

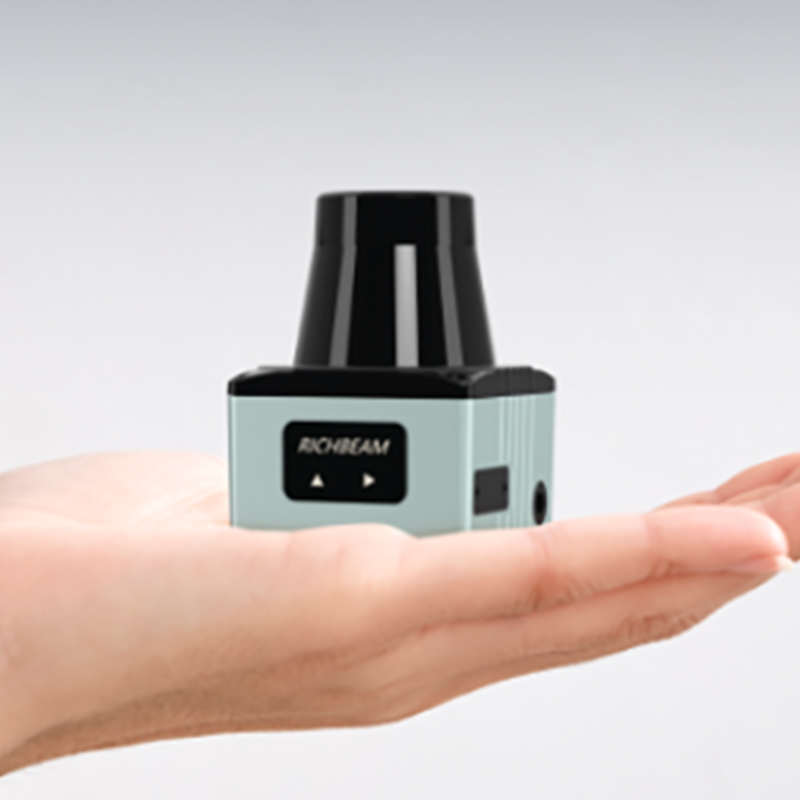

| 尺寸 | 长60mm,宽60mm,高80mm | |||

| 工作温度 | (-25°~60°) | |||

| 储存温度 | (-40°~75°) | |||

| 重量 | 160g | |||

| 工作电压 | 9~36V | |||

| 功耗 | ≤2W | |||

| 数据输出格式 | UDP/USB | |||

| 数据传输方式 | UDP/IP(百兆以太网) | |||

| 激光器等级 | Class1人眼安全 | |||

| 波长 | 940nm | |||

| 防护等级 | IP65 | |||

| 单品包装尺寸 | 19.4x12.7x11 厘米 | |||

技术创新

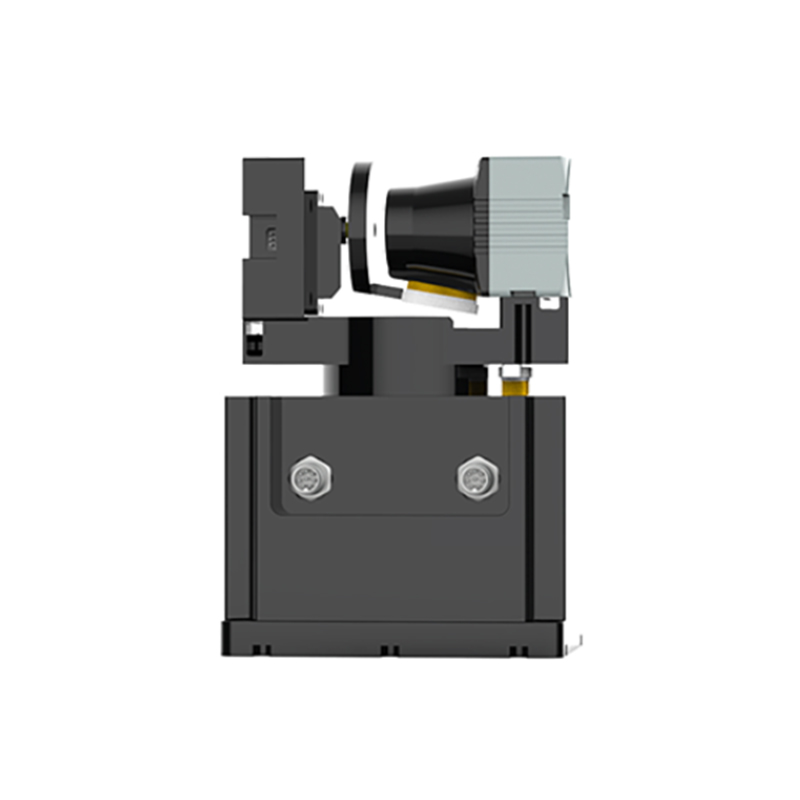

通过创新性自主研发,将激光雷达芯片技术与探测器的平台化设计紧密结合,搭配卓越的工业结构整合技术,实现了产品的更小型、更轻便的革命性突破。得益于锐驰智光光学性能的提升及算法的优化,LakiBeam系列在光面玻璃、室外强光高低温等恶劣环境下展现出卓越的适应力和抗干扰能力。

产品展示

始于才华 陷于品质

针对不同材质的应用场景进行模拟测试,在探测到不锈钢板、大理石瓷砖、玻璃、反光条、钻石级反光条、细杆、直角凹槽等材质时,锐驰智光激光雷达的点云能完美展现出被探测物体的形状。

1000次+破坏性测试,拥有极强的防撞能力。同时针对不同光照强度、温度、湿度、反光度、尘土、雾水对LakiBeam系列进行模拟测试 结果显示点云数据在边缘、纹理和特征线上的性能表现优异,稳定性极高。 可靠性与量产交付能力保证。

发射模块基于VCSEL光源的近圆形光斑,相对于EEL激光器,VCSEL激光器可以识别光斑更小,功耗更低,从而减少拖尾的产生,进一步提高点云精度。

锐驰智光在苏州拥有生产基地,占地面积近3000㎡,配备了先进生产设施与自动化流程,确保我们能迅速应对各种规模的交付需求从精细定制到大批量生产均游刃有余。

品控

- 校准设备精度:使用高精度的校准设备和仪器对激光雷达进行校准和标定,如高精度的测距仪、角度仪等,并定期对校准设备进行校准和维护,确保其精度和准确性。

- 校准方法与流程:制定科学合理的校准方法和流程,严格按照标准操作程序进行校准和标定工作,保证校准结果的一致性和可靠性。例如,对激光雷达的距离测量进行多点校准,对角度测量进行全方位校准等。

- 校准数据记录与追溯:对校准过程中产生的各项数据进行详细记录和保存,建立校准数据档案,以便对产品的质量状况进行追溯和查询,同时也为后续的质量改进提供数据支持 。

应用案例

激光雷达的应用非常广泛,以下是一些常见的应用领域:

- 自动驾驶领域:高精度定位结合高精度地图,激光雷达可以通过对周围环境特征的识别和匹配,实现车辆的高精度定位,确定车辆在地图中的准确位置,从而为自动驾驶的路径规划和导航提供可靠的基础。

- 机器人领域:导航与定,工业机器人、服务机器人、仓储物流机器人等可以利用激光雷达获取周围环境的信息,实现自主导航和精确定位,从而在复杂的环境中准确地移动到目标位置,完成各种任务,如物料搬运、清洁、巡检等。

- 智能交通领域:交通流量监测,安装在道路上方或路边的激光雷达可以实时监测道路上的车辆流量、速度和密度等信息,为交通管理部门提供准确的数据支持,以便更好地进行交通信号控制、拥堵疏导和交通规划。

服务

- 安装调试:协助客户进行激光雷达的安装和调试工作,确保设备能够正常运行。激光雷达的技术支持包括产品安装、调试等服务,帮助客户更好地使用和维护产品

- 使用培训:为客户提供产品使用培训,使客户能够熟练掌握激光雷达的操作方法和注意事项,正确使用设备,延长设备使用寿命。

- 问题咨询解答:客户在使用过程中遇到问题时,可随时向售后技术支持团队咨询,技术人员会及时解答疑问,提供解决方案。

- 远程协助:通过电话、邮件、在线客服等方式,为客户提供远程技术支持,帮助客户解决一些简单的问题,快速恢复设备运行。