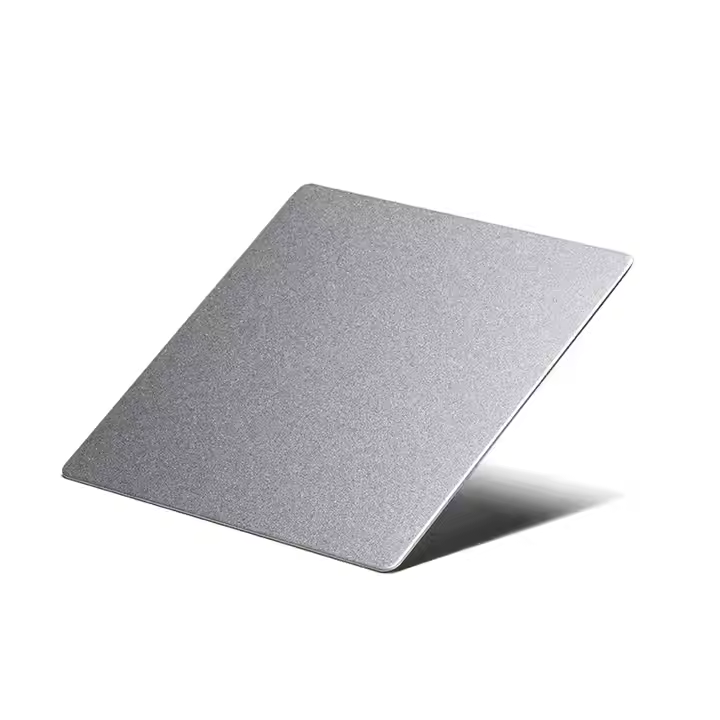

Product Description

CNC Milling Part refers to a component that is created using a CNC (Computer Numerical Control) milling machine. The milling process involves rotating a cutting tool to remove material from a workpiece, shaping it into the desired form. CNC milling offers high precision and the ability to create complex shapes, patterns, and designs. It is used for a wide range of materials such as metals, plastics, and composites.

Product parameters

| List | Details |

|---|---|

| Item Name | Metal CNC Milling Parts With Different Kinds |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM |

| Micro Machining or Not | Micro Machining |

| Model Number | Milling Parts |

| Available Materials | Titanium,Aluminum,Brass,Copper,Stainless Steel,Steel Alloy |

| Available Processing | 3 4 5 6 Axis CNC Machining |

| Surface Treatment | Sandblasting,Plating,Anodizing,Dusting As Your Order |

| Item Style | Bright And Clean,Safety |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Material

Silver

Brass

Copper

Quality Control

Quality control in custom precision CNC machining ensures that each part meets strict tolerances and performs optimally. It includes material inspection, dimensional checks, and surface quality assessments. CNC machines are regularly calibrated for accuracy, and final products undergo tests for hardness, strength, and durability. These steps ensure the parts meet industry standards and perform reliably in their intended applications

Processing capability

Custom precision CNC machining is capable of producing parts with high accuracy and complex geometries. It utilizes advanced CNC machines to achieve tight tolerances and smooth finishes, allowing for efficient material removal and optimal performance. This process can handle a variety of materials, including metals, plastics, and composites, making it versatile for many industries. The ability to work with high precision makes it ideal for demanding applications where detail and reliability are crucial

Additional processes

Additional processes for custom precision CNC machining include surface treatments such as anodizing, plating, and polishing to improve durability, corrosion resistance, and appearance. Heat treatment may also be applied to enhance hardness and strength, while deburring removes sharp edges for safer handling. These processes ensure that the final parts meet the required specifications and perform optimally in their applications