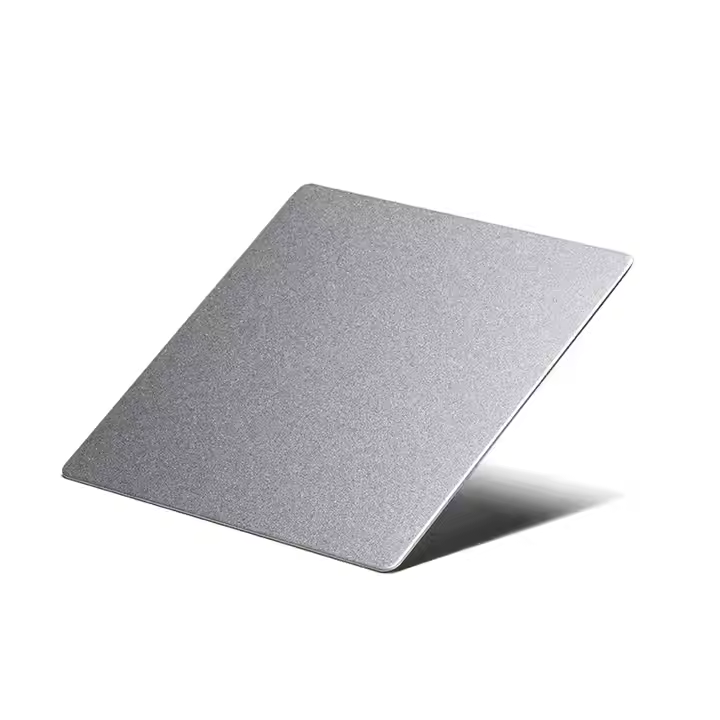

Product Description

The stainless steel bushing set is a high-quality component designed for durability and corrosion resistance. It is suitable for a variety of applications, providing excellent stability and helping to reduce friction in machinery systems. This extends the lifespan of moving parts. The set ensures precise installation, making it ideal for use in the automotive industry, general industry, and heavy machinery, where performance and reliability are crucial for operations.

Product parameters

| List | Details |

|---|---|

| Brand Name | CNC Machining |

| Material Capabilities | Aluminum, Brass, Copper, Hardened Metals, Stainless Steel, Steel Alloys, Bronze Copper, Precious Metals |

| Types | Compression, Drilling, Acid Milling/Chemical Cutting, Laser Cutting, Milling, Turning Services, EDM Wire Cutting, Rapid Prototyping |

| Micro Cutting | Yes, Micro Cutting |

| Processing Types | CNC Milling, Turning, Deburring, Surface Treatment, etc. |

| Surface Treatment | |

| Applications | Machinery parts and manufacturing services |

| Samples | Metal Sheet Stamped Aluminum Parts, Spare Parts Available |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Material

Silver

Brass

Copper

Quality Control

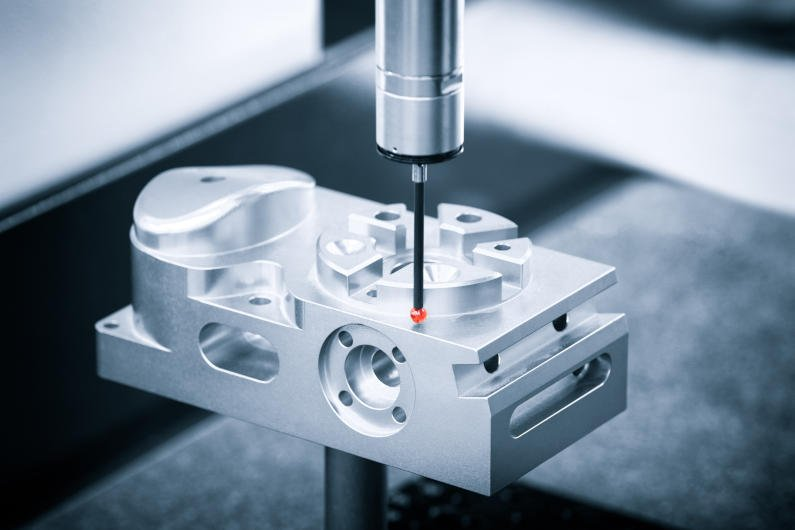

The quality control for the stainless steel bushing set ensures that each component meets established standards in terms of accuracy, durability, and performance. This process includes material inspection for defects, size measurements to ensure tight tolerances, and hardness testing for wear resistance. Surface inspections are conducted to ensure smoothness and the absence of defects, and each bushing is balanced to reduce vibration during use. These inspections help guarantee the reliability of the bushing set in high-demand applications.

Processing capability

The processing capabilities of the stainless steel bushing set include precision turning to create accurate sizes, tight tolerances, and smooth surfaces. These bushing components are manufactured using advanced techniques such as CNC turning, which ensures high efficiency and consistent quality. The material properties allow the production of bushings that are durable and wear-resistant, making them suitable for use in a wide range of industries.

Additional processes

Additional processes for the stainless steel bushing set include surface treatments such as polishing to achieve a smooth finish, plating to enhance corrosion resistance, and heat treatment to increase hardness and durability. These processes ensure that the bushings perform reliably under stress and are resistant to wear, making them ideal for use in high-demand applications.

4o mini