Product Description

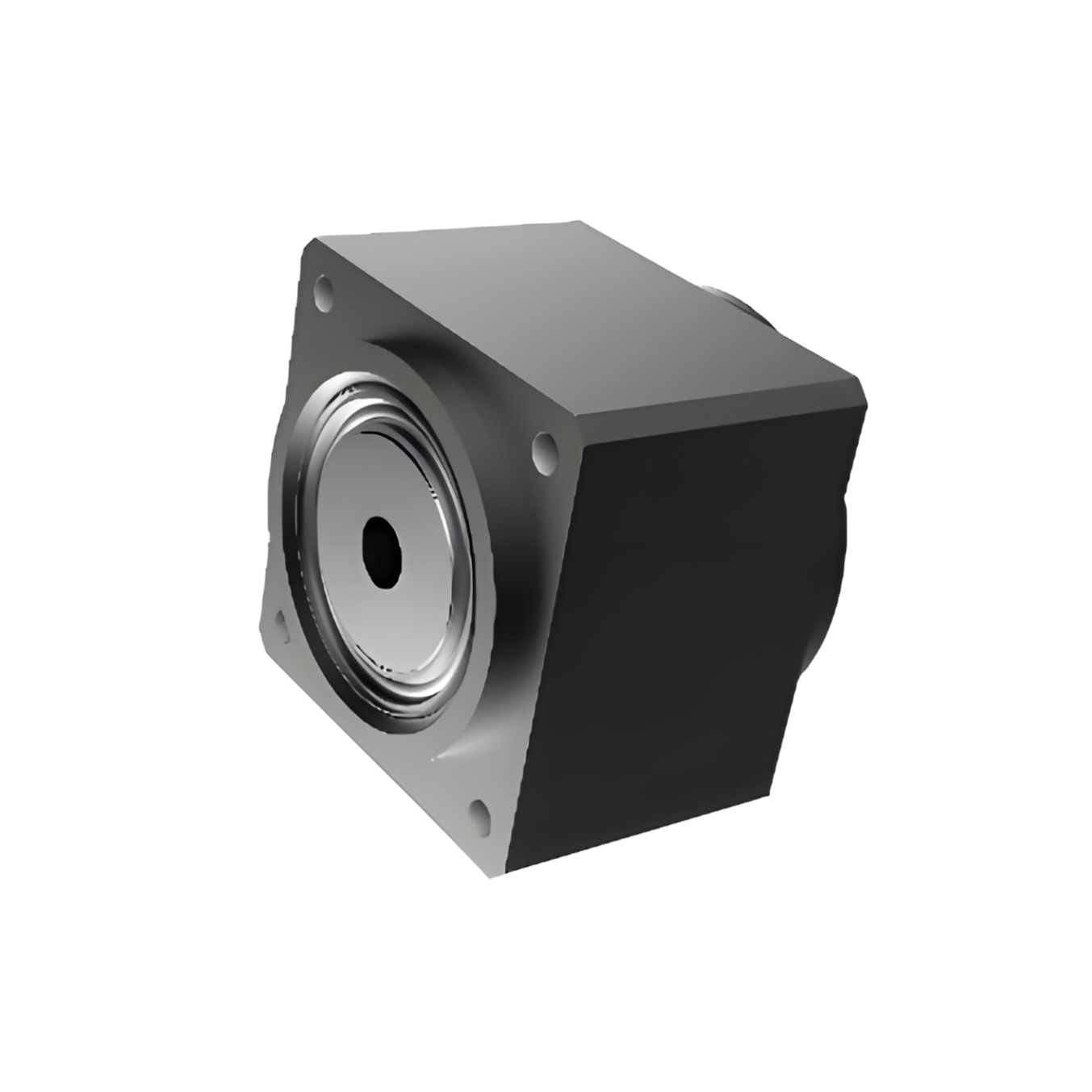

Small size and light weight, this is one of the most striking features of the mini harmonic reducer. Its small size allows it to be adapted to application scenarios with limited space, such as small robots, precision instruments and equipment, etc. Compared with traditional reducers, mini harmonic reducers have great advantages in size and weight, which can effectively reduce the overall weight of the equipment and improve the portability and operability of the equipment.

Product parameters

| Reduction ratio | 30 | 50 | 80 | 100 |

| Input rated torque at 2000r/min | 2.1Nm | 3.2Nm | 4.2Nm | 4.8Nm |

| Allowable peak torque at start and stop | 4.1Nm | 7.8Nm | 9.5Nm | 10.5Nm |

| The max. allowable torque of the average load | 3.1Nm | 5.1Nm | 7.2Nm | 8.7Nm |

| Instantaneous maximum allowable torque | 8.2Nm | 15Nm | 20Nm | 23Nm |

| Backlash | ≤20Arcsec | ≤50Arcsec | ≤10Arcsec | ≤10Arcsec |

| Maximum input speed allowed | 8500rpm | |||

| Allowable average inputspeed | 3500rpm | |||

| Rotational inertia(1/4GD) | 1.4x10² kgcm² 1.2x10-2 | |||

Technical features

Ultra small diameter bearings

Although the sparrow is small and has all the internal organs, the minimum number of micro-harmonic tooth molds is only 0.08 molds. Conventional tooth processing tools cannot do the job.

The smallest diameters of crossed roller bearings and flexible bearings are only 5mm and 12mm. These three major metal cutting technical difficulties are the main reasons that limit the development of micro-harmonics.

Xintuo's technical team teamed up with technical experts in various fields to conduct innovative research and gradually solved related problems.

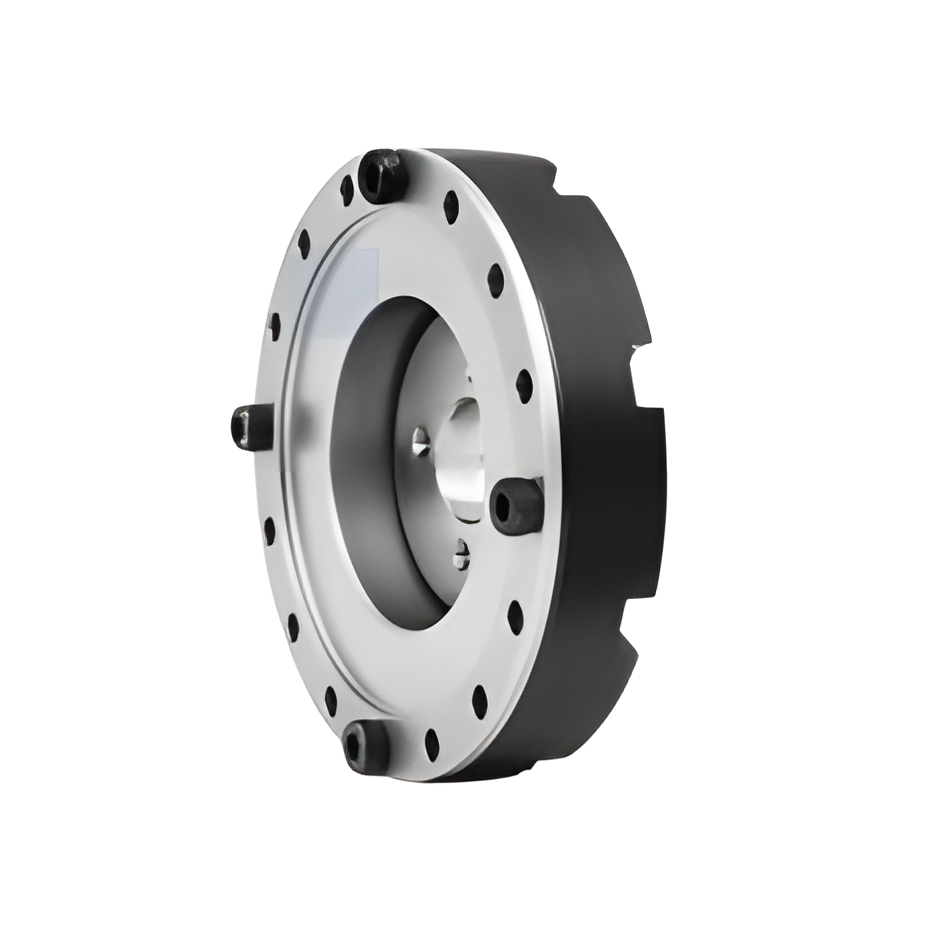

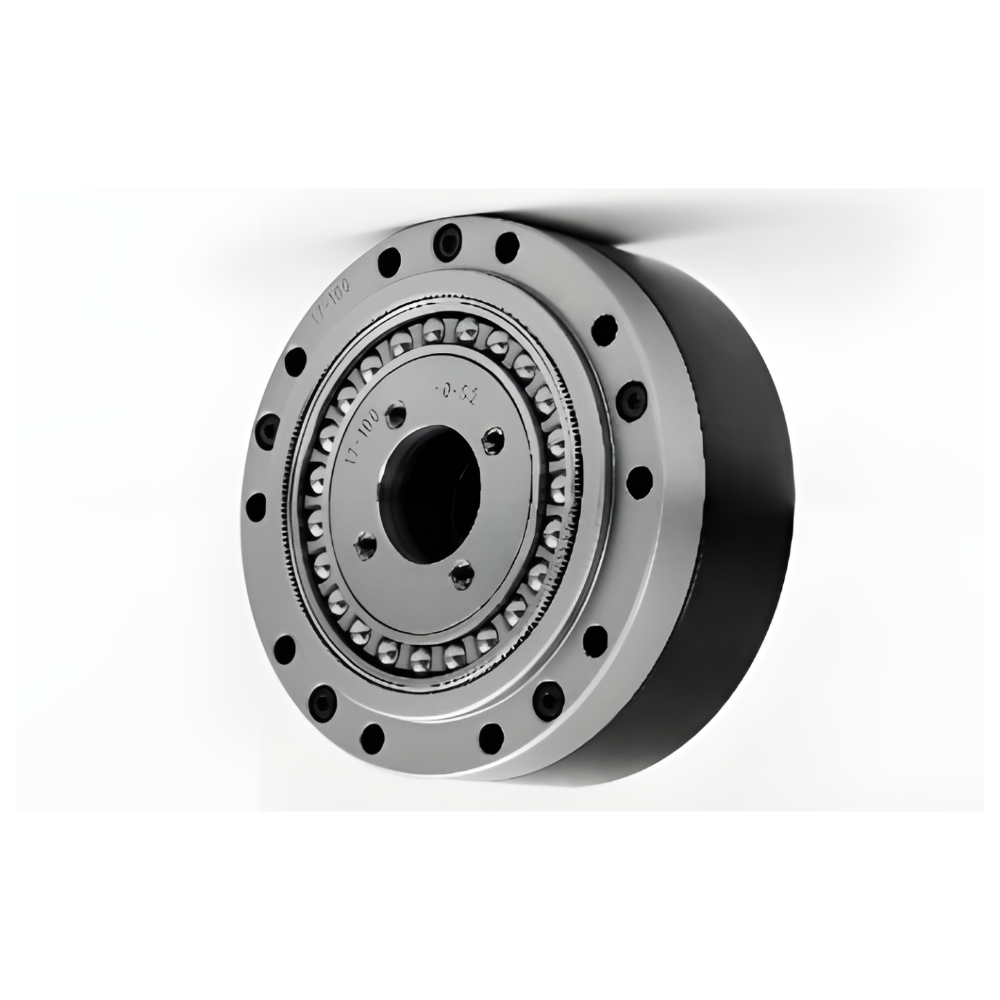

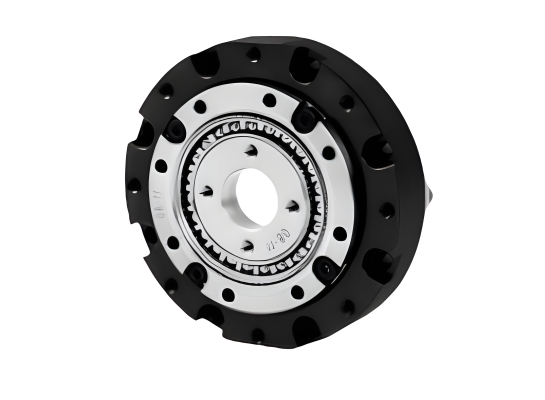

Product Display

In tooth profile design, we use advanced computer-aided design technology and theoretical mechanics analysis methods to conduct in-depth research on the influence of different tooth profile parameters on transmission efficiency, accuracy and load-bearing capacity, design a variety of innovative tooth profile structures, and optimize and verify them through a large number of simulation experiments and actual tests.

With the rapid development of science and technology, harmonic drive technology is also constantly evolving. The research and development and application of new materials have brought more excellent mechanical properties and durability to components such as flexible wheels, enabling them to operate stably under more stringent working conditions. At the same time, the introduction of advanced manufacturing processes such as precision CNC machining and special molding technology has made a qualitative leap in the manufacturing accuracy and production efficiency of harmonic drive devices, further reducing production costs and improving the market competitiveness of products.

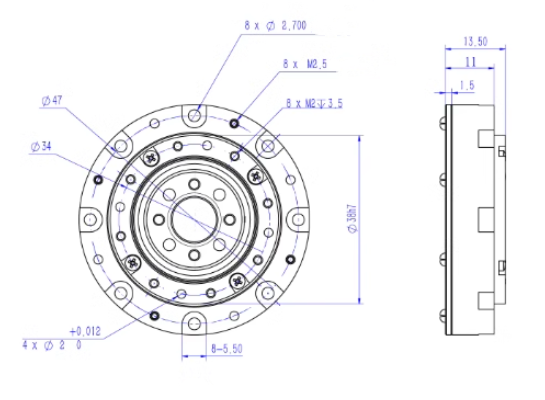

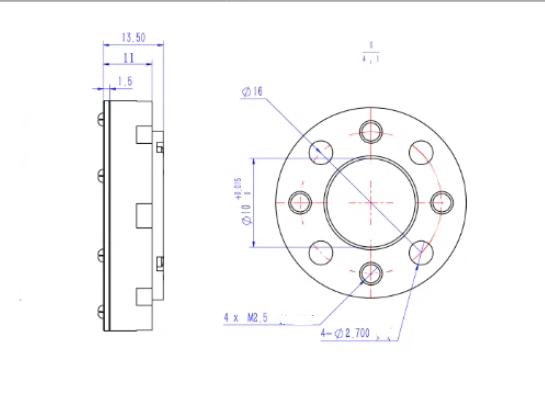

Size & Interface

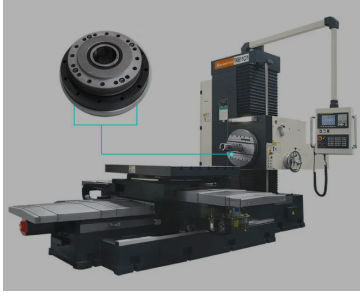

Application Cases

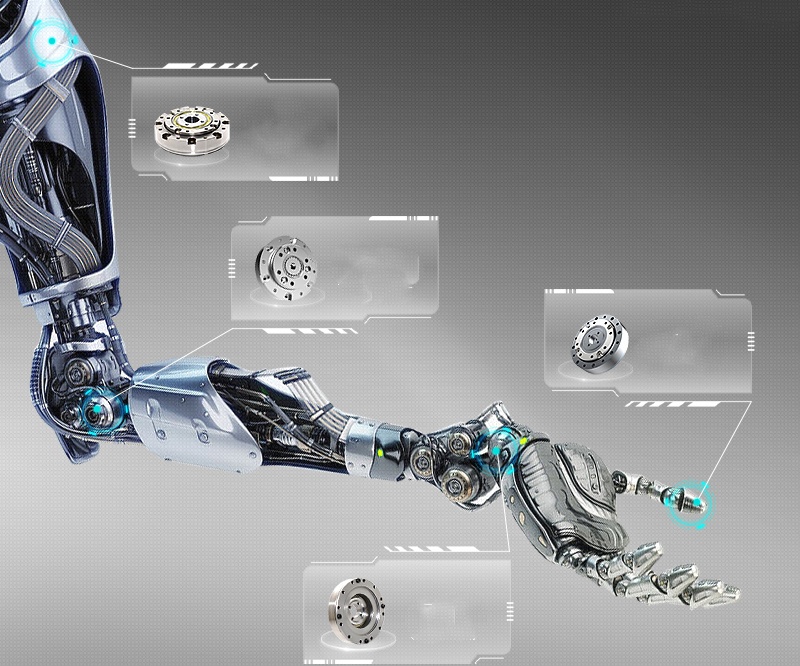

The harmonic reducer is small in size and light in weight, and can be installed in the small space of the robot hand to provide precise power transmission and motion control for the hand joints, allowing the robot hand to achieve flexible movements. In addition, the low vibration and low noise characteristics of the harmonic reducer also help reduce vibration and noise during hand joint movements, improving the operational stability and quietness of the robot. The limbs of humanoid robots need to complete various complex and delicate movements, such as grabbing objects, walking, climbing, etc. The harmonic reducer has high transmission accuracy, which can ensure that the robot's limb joints accurately reach the predetermined position and achieve high-precision motion control.