Product Description

Intelligent welding special RGBD stereo camera, used in industrial welding field. It uses 3D vision technology to realize precise positioning of workpiece, relies on image recognition and feature extraction algorithm to complete weld extraction, and realizes weld tracking function through real-time visual feedback and dynamic tracking algorithm.

Product parameters

| specification | argument | specification | argument |

|---|---|---|---|

| Model number | SVersion-HJ-RGBD-90 | Typical full frame acquisition time | 0.2~0.8s |

| Feature | Weld extraction + weld tracking +RGB original | Maximum line sweep rate | 3000 lines /s |

| Intelligent development platform | Tiger ® Platform | Color image resolution | RGB 4096*3000 |

| Interpupillary distance | 90mm | Output data format | RGB+ point Cloud data (Pcd, Las, Txt) |

| weight | 0.9kg | Front-end operation | Output results directly, without the need for other hardware platforms |

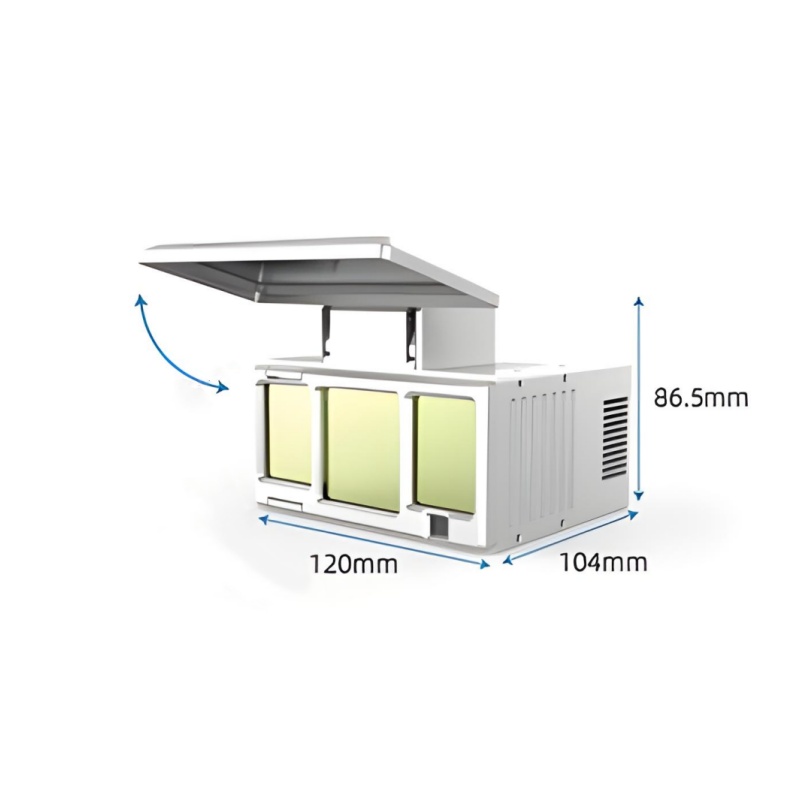

| dimension | 120*104*86.5mm | Resistance to ambient light | 180000Lux |

| Working distance | 300~800mm | Operating ambient temperature | -20℃~50℃ |

| Near field of view | 460 x290mm @300mm | Communication interface | Gigabit Ethernet |

| Far field of view | 1150x680mm @800mm | illuminant | Blue laser (450nm), infrared laser (808, 850nm) |

| Z-direction single point repetition accuracy *1 | 0.02mm @300mm 0.125mm @800mm | Power input | 24V DC,1.1A |

| VDI/VDE measurement accuracy *2 | 0.35mm @300mm 1mm @800mm | Class of protection | IP65 |

Technological Innovation

Lightweight and small in size

The electric anti-splash cover can better protect the lens, adapt to harsh environment, automatically close the anti-splash cover after scanning, and the SDK is controllable

Product Display

RGBD stereo camera for intelligent welding has the characteristics of high precision and high frame rate. Its high precision is due to advanced optical measurement and precise algorithm calibration, which can control the error of workpiece positioning and weld parameters in a very small range. The high frame rate relies on high-speed image sensors and efficient data transmission technology to achieve fast image capture, which in combination greatly improves welding accuracy.

Intelligent welding special RGBD stereo camera has strong anti-interference ability. In the anti-glare, the diaphragm adjustment and automatic exposure control technology are used to deal with the problem. In terms of anti-reflection, polarized light filtering and multi-angle light compensation algorithm are used to solve the problem. Light absorption is achieved with the help of highly sensitive sensors and adaptive gain technology.

Size & Interface

Quality Control

In the field of industrial welding, our rigorous quality control of RGBD stereo cameras for smart welding ensures excellence in workpiece positioning, weld extraction and weld tracking functions.

Application Cases

It can be applied to welding many kinds of non-standard workpieces with large assembly errors and small batches, such as steel structure, construction machinery, steel bars, civil air defense doors, tube plates and other welding scenes, helping users significantly improve production efficiency.

Cooperative partner

Service

We have established a perfect after-sales service system. If the RGBD stereo camera for smart welding fails during use, whether it is a sensor problem affecting the positioning of the workpiece, a fault in the image processing unit resulting in inaccurate weld extraction, or an abnormal weld tracking function, our maintenance team will respond quickly. Through remote diagnosis, you can restore the normal operation of the camera as soon as possible to reduce the impact on you.