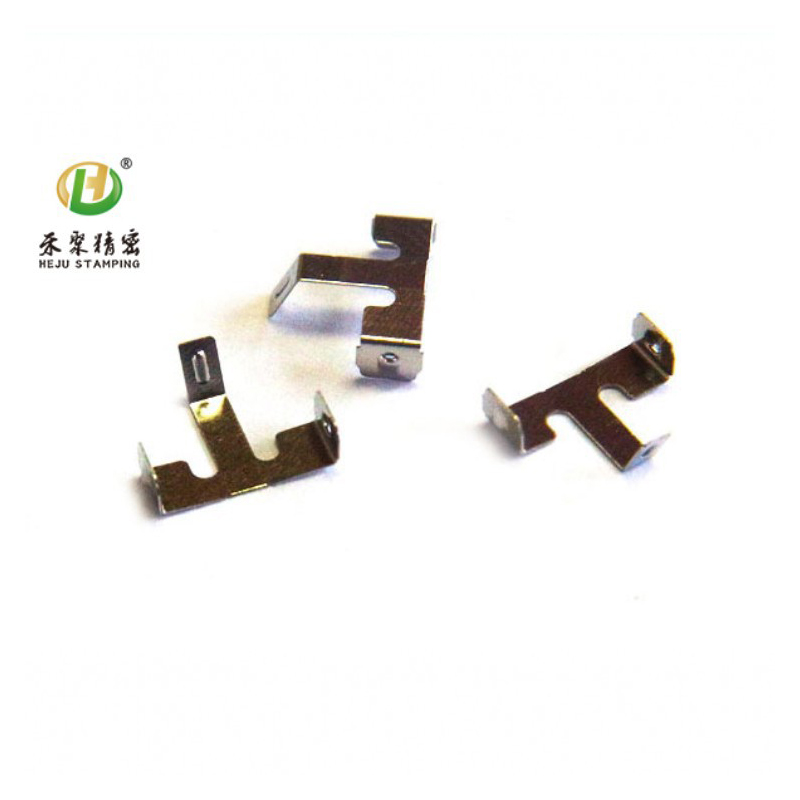

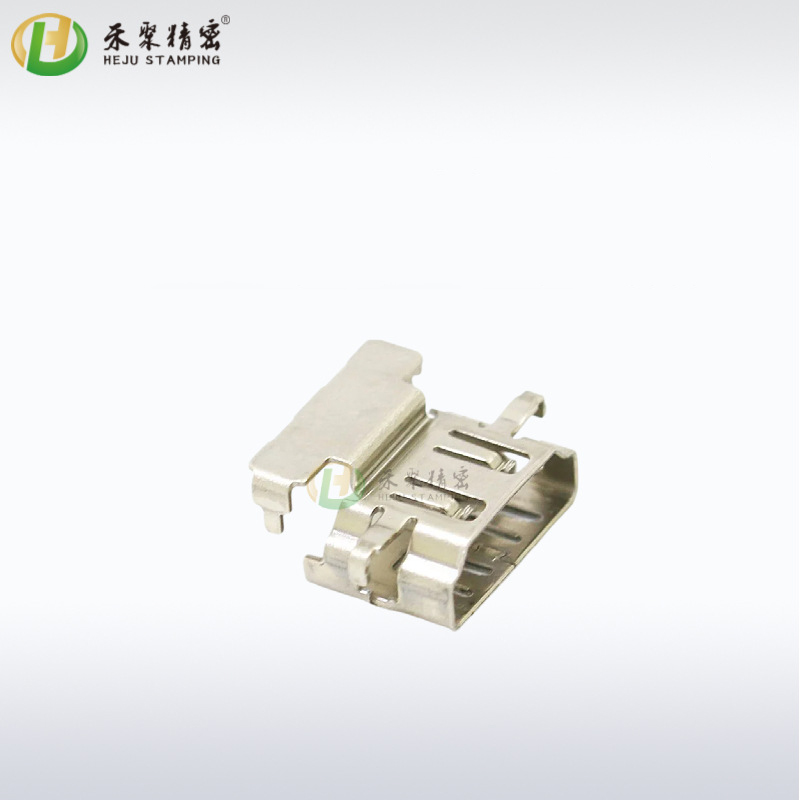

产品描述

我们专注于非标精密冲压业务,专业供应各类高品质的非标精密五金件。其中包括继电器五金件冲压件,其工艺精湛,能精准契合继电器的复杂构造与性能要求。同时,我们在太阳能不锈钢金属制品方面也极具优势,这些制品凭借我们先进的冲压技术,在精度、强度和耐用性等方面表现卓越,为太阳能相关设备的稳定运行提供有力保障,满足您对高质量非标精密五金制品的需求。

产品参数

| 参数名 | 参数值 | 参数名 | 参数值 |

|---|---|---|---|

| 品牌 | 禾聚 | 可加工厚度 | 0.5-20mm |

| 可加工材料 | 不锈钢,铜,铝 | 冲压工艺 | 成型+拉伸,折弯,翻边 |

| 表面处理 | 工艺镀层 | 最小加工尺寸 | 0.1 |

| 打样周期 | 4-7天 | 加工件应用领域 | 汽车行业,医疗器械 |

| 加工周期 | 1-3天 | 尺寸精度 | ±0.2mm |

| 最大加工尺寸 | 500 | 品名 | 继电器五金件 |

| 类别(公/母) | 银角触点 | 材质 | k88 T=0.3 |

| 电镀规格 | 洗油 | picth | 10 |

| 冲速 | 300 | 尺寸公差 | +/-0.02 |

| 平面度 | +/-0.02 | 垂直度 | +/-0.02 |

| 直线度 | +/-0.02 | 特点 | 1、同前面描述2、弹片材质要求耐插拔性能高,电阻小。3、弹片的冲压生产与银角触点的铆合需在模内同步完成,自动化程度高,节约工时。4、生产效率高,每小时可产出达到3万pcs以上。 |

| 用途 | 继电器开关用金属触点弹片 |

定制流程

1.需求沟通

2.方案设计

3.报价签约

4.模具制造

5.材料采购

6.冲压生产

7.后处理

8.验收交付

工艺种类

- 精冲:属于无削加工技术,是在普通冲压技术基础上发展起来的一种精密冲压方法,它能在一次冲压行程中获得比普通冲压零件尺寸精度高、表面粗糙度好、互换性好的优质冲压零件,主要用于生产汽车、摩托车、电子、仪器仪表等行业中的一些形状复杂、尺寸精度高、表面质量好的薄板类零件,如汽车的同步器齿环、摩托车的启动盘等。

- 微冲压:是指零件尺寸在微米级范围内的冲压加工技术,其冲压件的尺寸精度可达到微米级甚至更高,主要用于制造微小尺寸的零件,如微型传感器、微型齿轮、微型弹簧等,在电子、医疗、航空航天等领域有着广泛的应用,例如微型电子设备中的连接件、医疗器械中的微型零件等。

- 传递冲压:是一种多工位冲压工艺,它采用多个工位的模具,通过机械手或其他传送装置将工件从一个工位传递到下一个工位,在每个工位上完成不同的冲压工序,直至最终完成整个零件的冲压加工,这种工艺适合生产形状复杂、尺寸较大且精度要求高的冲压件,如汽车车身的大型覆盖件等。

材料

镁

铜

不锈钢

铝

品控

精选优质材料

从源头保障产品安全、寿命长

与国内外知名品牌原材料厂家(如日矿,维兰德等),模具钢材(日立,大同等)及粉未冶金厂家建立良好的互动关系,确保弹片端子用材料的正宗性

能为其电子部品的核心冲压件提供品质保证(如产品的弹片的弹性寿命,弹片表层盐雾测试,端子环保测试等安全指标等)

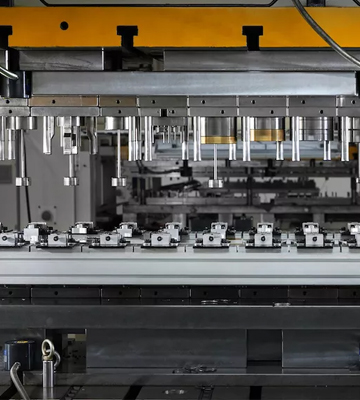

加工能力

冲压工艺

冲压:通过模具将铁片(金属片材)在冲床上加工成想要的形状。

分离(下料):分离简单了解就是将片材冲裁成所需的平面形状,

成型: 如折弯、拉深、旋压、整形、翻边、缩口,卷圆等属于成型工艺。

禾聚精密的设备精度可以达到±0.01mm。设备的吨位从25T-160T各种吨位冲床。均为日本或者台湾品牌冲床。全部为高速龙门冲和C型冲床。

分钟冲速最快可达1500次/分。具体参数请看生产设备一栏的简介。

附加工序

- 电镀:通过电解作用,在冲压件表面沉积一层金属或合金,以提高冲压件的耐腐蚀性、耐磨性、导电性等性能,同时还可以改善其外观。常见的电镀层有镀锌、镀铬、镀镍等,如汽车发动机的一些零部件经过镀锌处理后,可有效防止生锈,延长使用寿命。

- 化学镀:是一种不需要外接电源,利用还原剂将溶液中的金属离子还原并沉积在冲压件表面形成镀层的方法。化学镀可以获得均匀、致密的镀层,且不受冲压件形状和尺寸的限制,对于一些形状复杂的非标精密冲压件尤为适用,如电子设备中的一些微小零件可通过化学镀镍来提高其导电性和耐腐蚀性。