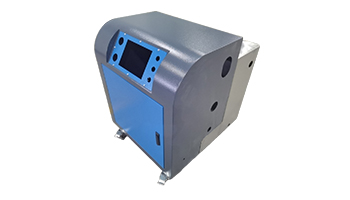

Product Description

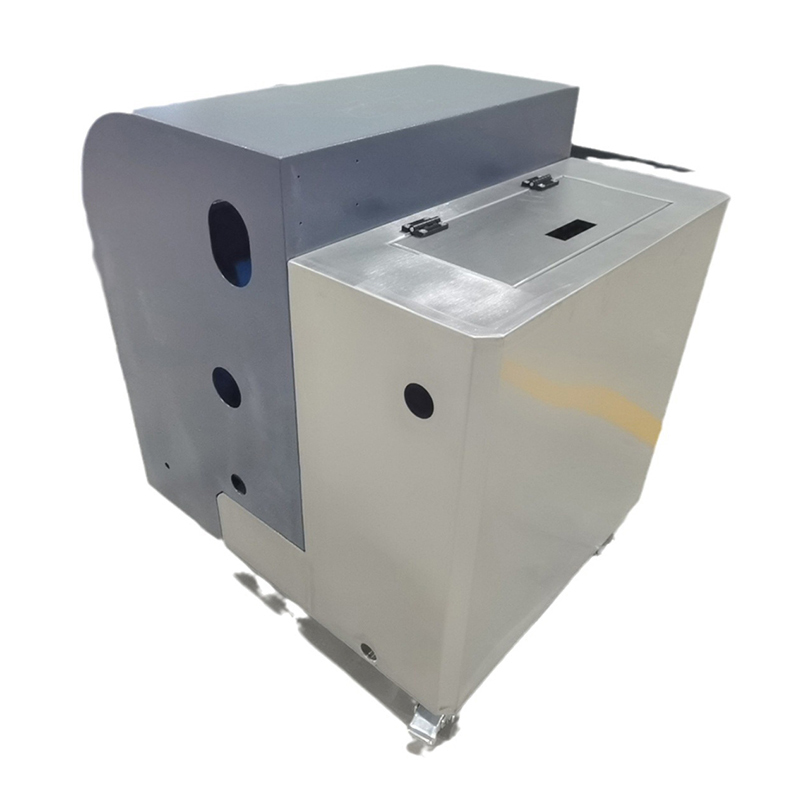

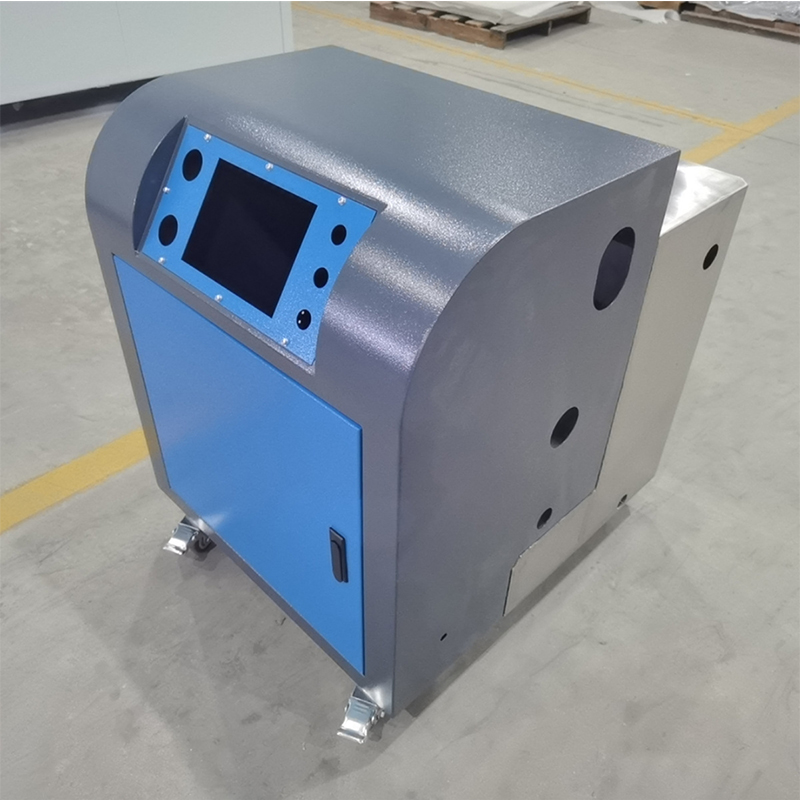

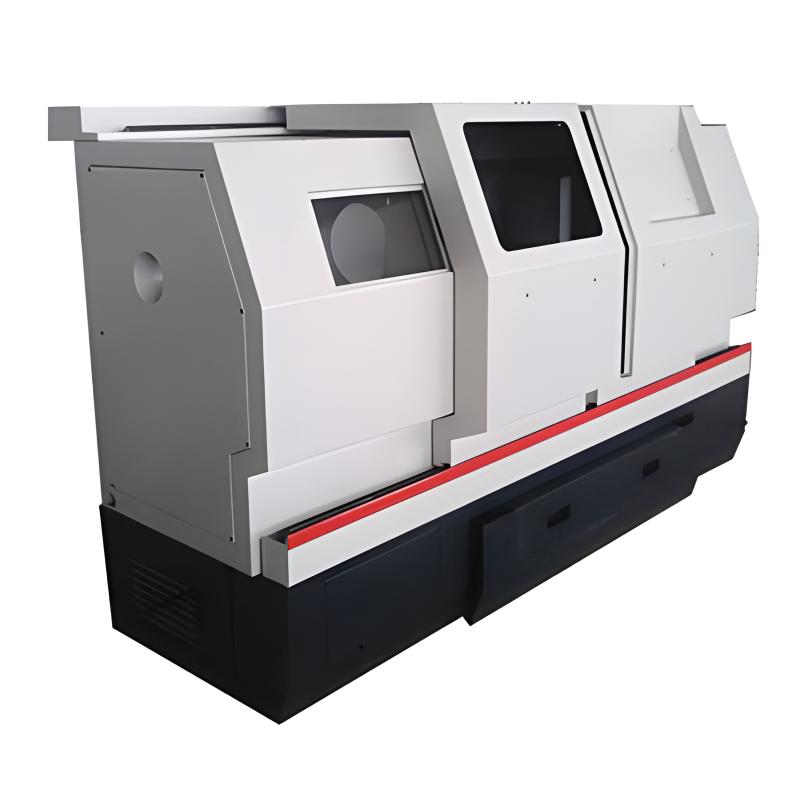

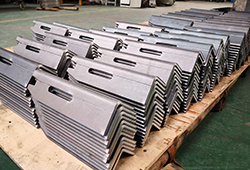

The cabinet shell sheet metal uses sheet metal technology to process metal sheets to make them into machine tool shells, protective devices, operating tables and other parts. The cabinet shell structure is solid and usually consists of parts such as a frame and side panels. The frame is made of high-strength metal materials such as high-quality carbon steel or aluminum alloy. After careful processing and assembly, it has excellent load-bearing capacity and can withstand the weight of the equipment itself and possible external impacts. The connection between the side panels and the frame is tight and firm, ensuring the stability of the overall structure of the cabinet.

Product parameters

| Name | Parameters | Name | Parameters | Name | Parameters |

|---|---|---|---|---|---|

| Name | Cabinet sheet metal | Material | Cold-rolled plate | Surface treatment process | Sandblasting, polishing, other |

| Sheet thickness | Customized (mm) | Processing size/length*width*height | Customized (mm) | Dimensional accuracy | ±1mm |

| Molding parts | Terminal equipment cabinet housing | Cutting method | NC cutting | Processable thickness | 0.1-15.0mm |

| Surface treatment | Baking paint | Surface roughness | Customized | Sheet metal process | Laser cutting, punching, welding |

| Proofing cycle | 7 days | Processing cycle | 8-15 days | Assembly service available | Assembly service available |

| Application areas | Electricity, industrial equipment, public facilities | Specifications | Cabinet sheet metal consultation customer service | Maximum/minimum processing size | Customized |

Custom Process

1. Sheet metal design

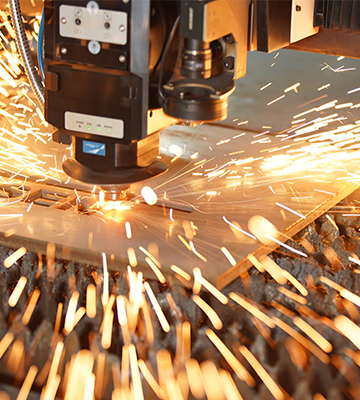

2. Laser processing

3. Digital punching processing

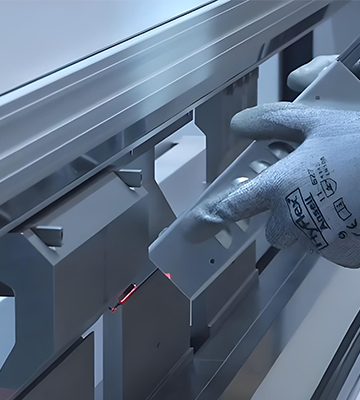

4. Bending processing

5. Pliers riveting processing

6.Welding processing

7. Surface spraying

Process Type

Laser cutting: Use a high-energy-density laser beam to irradiate sheet metal materials, causing the materials to melt or vaporize quickly, thereby achieving cutting. This method has high cutting accuracy, can cut very complex shapes, and the cut surface is relatively smooth.

Bending process: Use a bending machine to bend the sheet metal. By adjusting the mold and pressure of the bending machine, the sheet metal material can be bent into various angles. During the bending process, the appropriate mold and bending process parameters should be selected according to the thickness, material and bending angle of the sheet metal material.

Welding process: low cost, high production efficiency, suitable for welding of medium and thick plates. In the welding of sheet metal structures of large machine tools, such as the welding of machine tool bases, carbon dioxide gas shielded welding is widely used.

Material

Ordinary carbon steel

Aluminum Alloy

Cold rolled sheet

High quality carbon steel

Quality Control

Raw material control: Verify the material, such as using a spectrometer to confirm whether it is the specified material. Check that the raw material size specifications are within the tolerance range. Evaluate the surface quality to avoid defects such as scratches and rust.

Process control: Cutting: Monitor the cutting size accuracy and cutting surface quality. Bending: Ensure the bending angle accuracy and appropriate bending radius. Welding: Check the quality and strength of the welded joint.

Processing capability

The company has multiple sets of sheet metal and testing equipment, including fiber optic laser cutting machines, CNC NCT punching machines, CNC folding machines, CNC hydraulic rivet machines, pressure forming machines, wire drawing machines, laser welding machines, spot welding machines, cold welding machines, argon arc welding machines, carbon dioxide welding machines, aluminum welding machines, painting and plastic spraying equipment, and is equipped with a professional 3D sheet metal process design team.

Additional processes

Riveting: Two or more sheet metal parts are connected together by rivets. After the rivet passes through the pre-drilled hole, one or both ends are deformed by special tools to form a strong connection. This connection method has certain reliability and shock resistance. It is often used in some occasions where the connection strength requirements are not particularly high but a simple and quick connection is required, such as the assembly of some simple metal shelves.