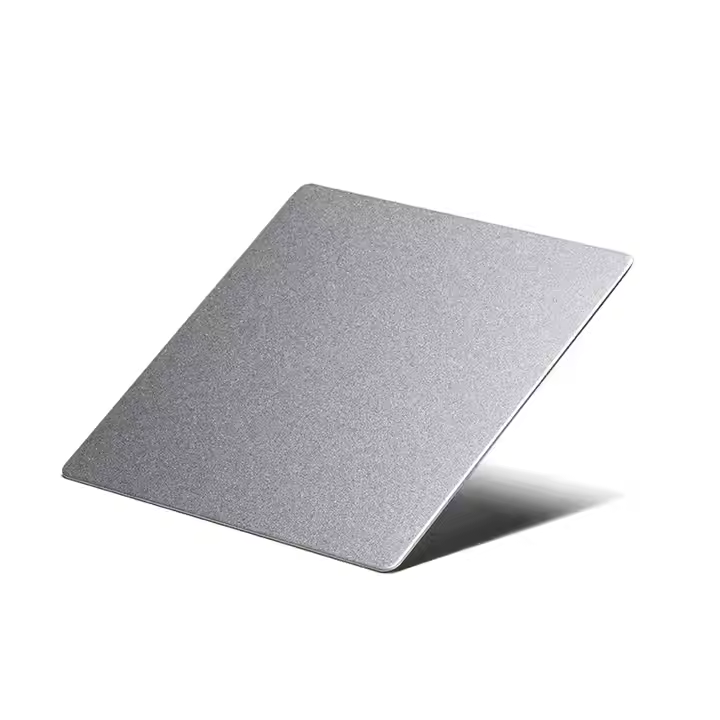

Product Description

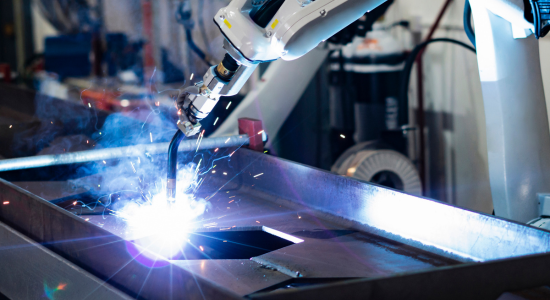

Our aluminum welding fabrication service uses advanced techniques like TIG and MIG welding to join or shape aluminum for various applications. Known for its lightweight, durability, and corrosion resistance, aluminum is ideal for automotive, structural, and consumer products. We deliver high-quality, precise welds for both small and large-scale projects.

Product parameters

| List | Details |

|---|---|

| Product name | Linear Guide Rail Block |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Retail, Printing Shops, Construction works , Advertising Company |

| Material | Aluminum alloy+Bearing steel |

| Type | Sliding |

| Application | Automation line railway/CNC machine |

| Performance | low friction,low noise,high speed |

| Funcion | Anti-friction,Dustproof |

| Service | OEM Customized Services |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Drilling

Milling

Turning

Material

Silver

Brass

Copper

Quality Control

Quality control in aluminum welding fabrication ensures structural integrity and compliance with standards by inspecting materials, preparing surfaces, and adhering to precise welding parameters. Post-welding checks, including visual and advanced testing, verify weld quality and dimensional accuracy. Proper environmental controls and equipment monitoring maintain consistency, with thorough documentation for traceability.

Processing capability

The processing capability of aluminum welding fabrication includes TIG and MIG welding for precise, strong joints, along with cutting, shaping, and surface preparation. Skilled operators and advanced machinery ensure tight tolerances and intricate designs. Post-welding treatments like grinding and polishing enhance durability and appearance, making it ideal for industries such as automotive, aerospace, and construction.

Additional processes

Additional processes in aluminum welding fabrication include surface cleaning, heat treatment to relieve stress, and finishing techniques like polishing, anodizing, or coating for enhanced appearance and corrosion resistance. Precision machining and assembly may also be performed to meet specific design and tolerance requirements.