Product Description

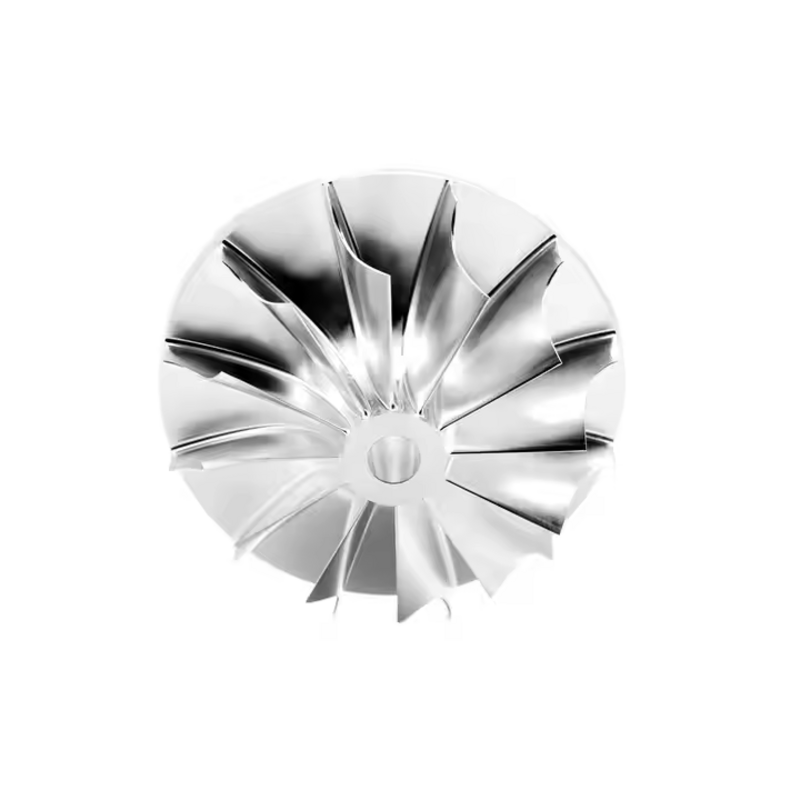

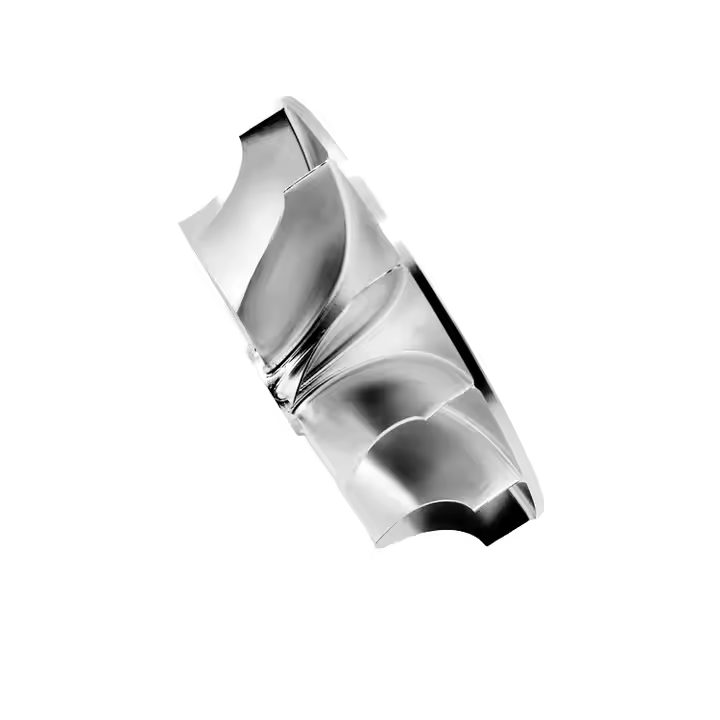

High-precision machining of components ensures durability, accuracy, and superior quality for industrial and specialized applications. With advanced machinery, it produces intricate designs with tight tolerances and flawless finishes. Ideal for industries like aerospace, automotive, and electronics, it delivers reliable, high-performance parts tailored to specific needs.

Product parameters

| Quotation | According to your drawing(size, material, required technology, etc) | |||

| Tolerance | +/-0.001 mm - 0.01 mm (Customized avaiable) | |||

| Surface Roughness | Ra0.2 - Ra3.2(Customized avaiable) | |||

| Processing | Turning, Milling , drilling, auto lathe, tapping, surface treatment, etc. | |||

| Drawing Formats | PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF | |||

| Our Advantages | 1. 24 hours online service . | |||

| 2. Quickly Quote/Delivery. | ||||

| 3. 100% QC quality inspection before delivery | ||||

| 4. Can provide quality inspection form. | ||||

| 5. 15+ years of experience in the CNC machining area | ||||

| 6. Have a senior design team to offer perfect modification suggestions. | ||||

| Custom CNC Machining Parts of Most Materials | ||||

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Hydraulic Machines

In hydraulic systems, brass components are used as connectors or adapters due to their ability to withstand high pressure and ensure tight sealing. This reduces leakage and improves system efficiency.

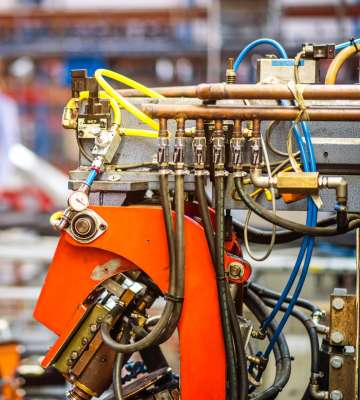

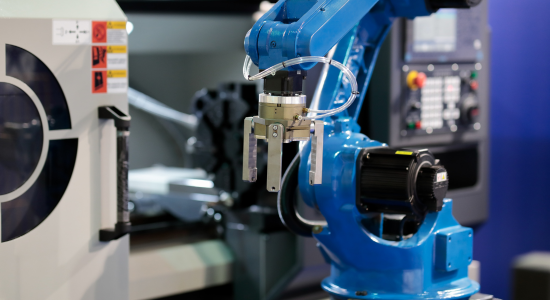

Industrial Machinery

Steel gear drives help machinery operate efficiently by supporting precise movements in the manufacturing process.

Manufacturing Equipment

Parts used in manufacturing machinery, such as parts in automation systems and tools used in the production of other products that require precision in operation to increase productivity.

Material

Copper

Aluminum Alloy

Stainless Steel

Quality Control

Quality control of components machining parts involves rigorous inspections throughout the manufacturing process to ensure precise dimensions, flawless finishes, and reliable performance. Using advanced measuring tools, each part is checked for tight tolerances and compliance with specifications. Continuous monitoring during production, combined with post-production testing, guarantees consistent quality and durability. This process ensures that every component meets the highest industry standards, delivering reliable, high-performance parts for diverse applications.

Processing capability

The processing capability of components machining parts includes handling complex shapes, achieving tight tolerances, and producing high-quality finishes. It supports a wide range of materials, including metals and plastics, and is capable of executing intricate designs for industries such as aerospace, automotive, and electronics. Using advanced CNC machinery, the process ensures consistent precision, efficient material use, and adaptability for both prototyping and large-scale production.

Additional processes

Additional processes for components machining parts include surface treatments such as anodizing, plating, and polishing to enhance corrosion resistance, appearance, and durability. Heat treatment may be applied to improve material strength, while secondary operations like threading, tapping, and engraving add functionality. Deburring, cleaning, and quality assurance checks ensure that each part meets the required standards for precision and performance, making them ready for use in various industrial applications.