Product Description

DS-R005 clutch digital servo makes a shocking debut! It has a powerful torque output of 2.2KG, can easily cope with various complex working conditions, and provide stable and accurate power support for the equipment. Its advanced clutch design effectively improves the safety and reliability of the equipment and avoids damage caused by overload. The use of digital control technology ensures that the servo responds quickly and moves smoothly during operation, with amazing accuracy. Whether it is precision control in the field of industrial automation or fine action execution in model making, the DS-R005 clutch digital servo will be your best choice with its excellent performance, making your project operation more efficient and stable, leading the new trend of the industry.

Product parameters

| Parameter name | Parameter Value |

|---|---|

| Operating Voltage | 4.8-6V DC |

| Static current | ≤10mA |

| Stall Current | ≤700mA at 4.8V,≤800mA at 6.0V |

| Stall Torque | ≥1.6kgf·cm at 4.8V,≥2.2kgf·cm at 6.0V |

| Rotating Direction | CCW(1000→2000μs) |

| Torque | 2.0kgf.cm at7.4v |

| No-load speed | ≤0.15sec/60°at 4.8V,≤0.13sec/60° at 6.0V |

| Speed | 0.12s/60° at7.4v |

| Pulse Width Range | 500~2500μs |

| Operating Travel Angle | 180° |

| Operating frequency | 1520μs/333Hz |

| Return Angle Deviation | ≤1° |

| Weight | 20g |

| Communication Interface | PWM |

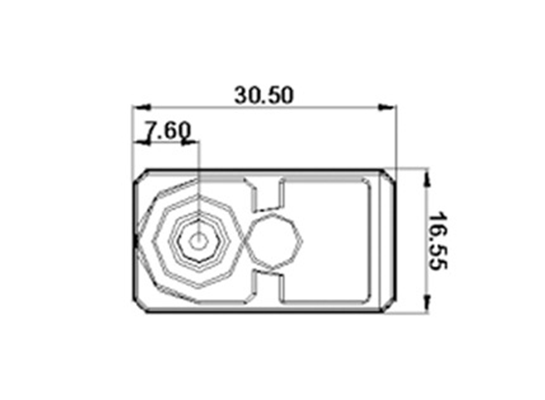

| Output shaft | 40T/Ф4.85mm |

| Plug | JR2.54 |

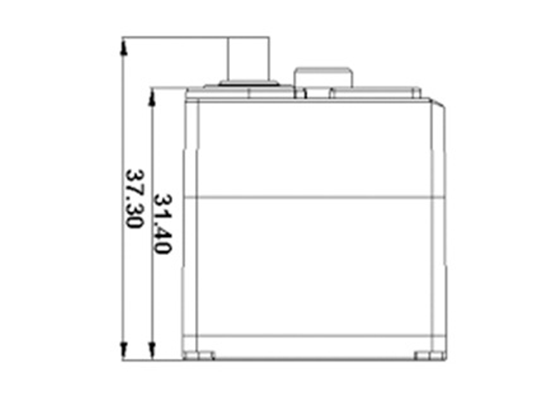

| Size | 1.20*0.65*1.23inch |

| Motor type | DC motor |

| Gear type | Plastics gear |

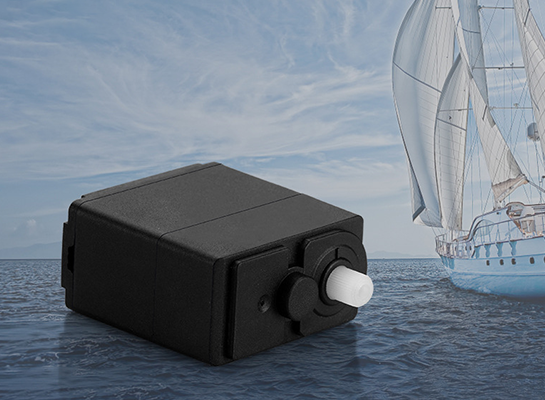

Product Display

CE . ROHS . FCC certification

Precise angle control 180° virtual position ≤1°

Unique clutch patent, anti-jumping gear | New plastic raw material gear, high strength

Iron core motor—high transmission efficiency

40T high-precision output gear for more stable use

Comes with electronic protection when leaving the factory

Power off protection after continuous load blocking for 5 seconds

Comes with standard rocker arm package for testing use

High precision plastic teeth

High-precision mold + automated injection molding machine;

Brand new plastic shell + iron core motor

Impact resistant, not afraid of burning

Imported potentiometer

Potentiometer life>500,000 times

Size & Interface

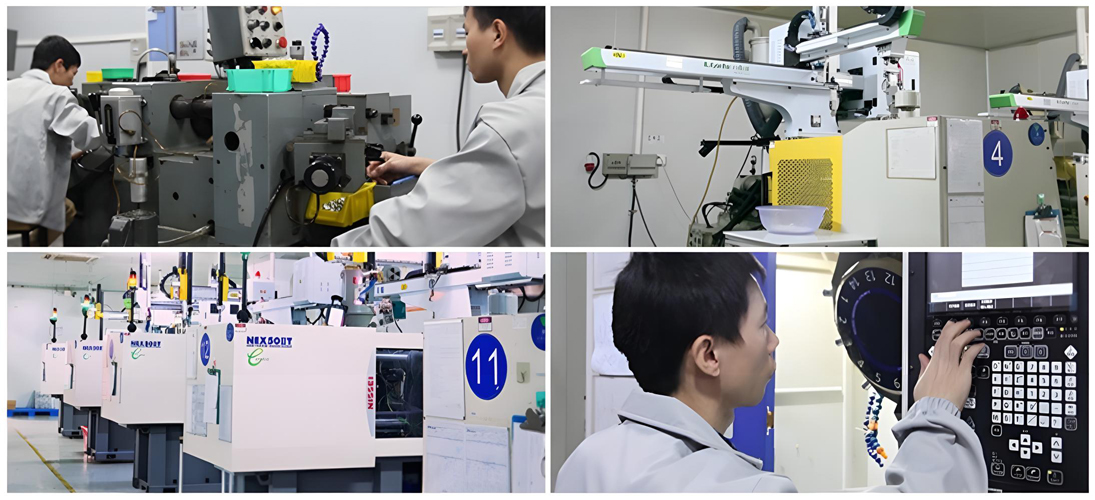

Quality Control

Imported raw materials, precision equipment, ISO certification system quality assurance

In our company, quality control runs through every link of production and operation. Advanced testing equipment and professional quality inspectors work closely together to accurately control product quality, and ensure that products always maintain excellent quality from the production line to the hands of customers with high standards and strict requirements.

Quality control is the foundation of our company. From the strict screening of raw materials, to the fine management of the production process, to the all-round testing of finished products before leaving the factory, every step embodies the persistent pursuit of quality, just to present impeccable products to the market.

The company always adheres to the strict quality control concept, starting from the source, optimizing the production process, strengthening quality inspection, and carving each product with ingenuity, so that high quality and reliability become the distinctive label of the company's products, winning the trust of customers and the recognition of the market.

Application Cases

- In industrial robotic arm applications, DS-R005 relies on 2.2KG torque for precise control, and the clutch device ensures stability and efficient completion of complex operation processes.

- In the field of intelligent robots, the servo uses its digital technology advantages to enable flexible movement of robot joints, and 2.2KG torque can easily cope with the needs of changing postures.

- In the control of high-end model aircraft, the fast response and appropriate torque of DS-R005 ensure the precise adjustment of the model aircraft's flight posture, and the clutch design enhances flight reliability.