Product Description

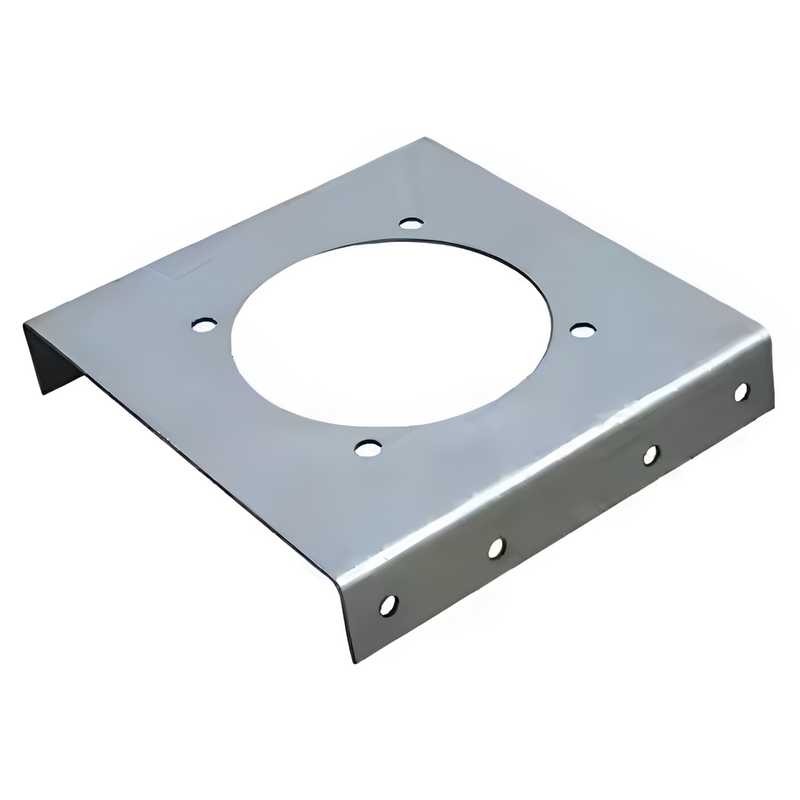

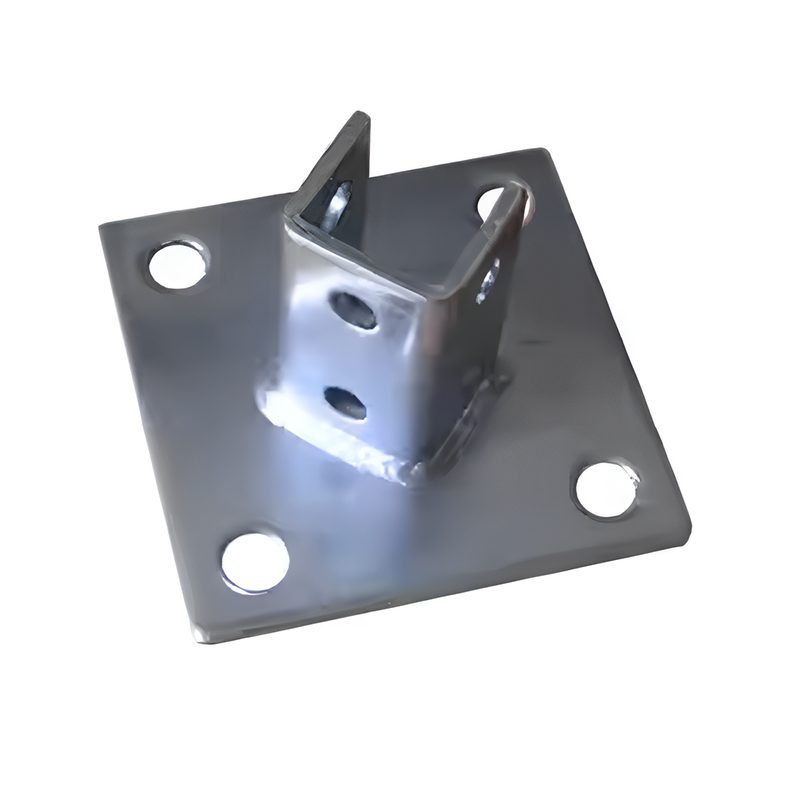

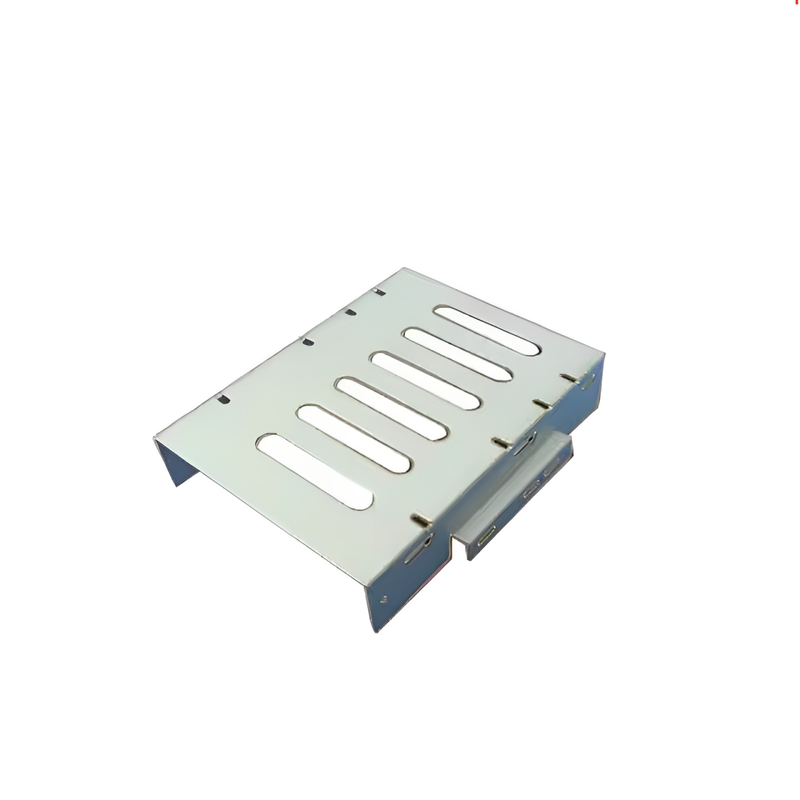

Durable steel metal stamping parts designed for superior strength, precision, and long-term reliability. Engineered to withstand demanding conditions, these parts are suitable for a wide range of industrial and automotive applications, including structural components, brackets, and enclosures.

Product parameters

| Product Name | Stamped Parts | |||

| Services | Customized OEM ODM | |||

| Delivery Time | According Customers | |||

| Material | Customized | |||

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

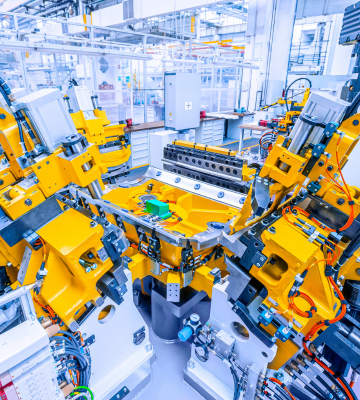

Industrial Machinery

- Reason: Parts in industrial machinery must be resistant to wear and tear and impact.

- Advantage: Stamped metal parts are strong and durable, making them suitable for heavy-duty industrial use.

Machine Parts

In heavy machinery, components such as gears, housings, and bearings are often made from cast iron or stainless steel. The durability and wear resistance of the materials are crucial to ensure that the machinery operates smoothly and lasts for an extended period.

Construction Equipment

- Reason: Scaffolding, metal frames, and tools used in construction require strength, load-bearing capacity, and shapes tailored to specific tasks. Custom bending stamping creates durable components that meet these demands effectively.

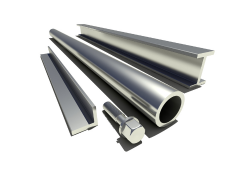

Material

Stainless Steel

Iron

Aluminum Alloy

Copper

Quality Control

Quality control for steel metal stamping parts ensures that each component meets precise specifications for strength, accuracy, and durability. The process includes rigorous inspections such as dimensional analysis, material hardness testing, and surface quality checks to detect any imperfections

Processing capability

The processing capability of steel metal stamping parts includes high-precision cutting, bending, and shaping to create complex designs with tight tolerances. Advanced stamping presses are used to handle various steel grades and thicknesses, ensuring consistent quality and performance. The process also supports additional operations such as punching,

Additional processes

Additional processes for steel metal stamping parts include surface treatments such as coating, plating, and painting to enhance corrosion resistance, appearance, and durability. Secondary operations like welding, assembly, deburring, and threading are performed to meet specific design and functional requirements. Laser cutting, punching, and engraving can also be applied for more intricate designs and precision.