Product Description

High-quality, custom precision CNC turned aluminum parts, designed to meet your exact specifications for durability, performance, and a perfect fit in various applications. Crafted with state-of-the-art CNC machinery, these components ensure exceptional dimensional accuracy and surface finish. Ideal for industries such as automotive, robotics, and industrial equipment, each part undergoes rigorous quality control to meet the highest standards.

Product parameters

| Product Material | 1) AL1060, AL6061, AL6061, AL5052 |

| 2) Steel, mild steel, SPCC | |

| 3) SS201, SS303, SS304, SS316, SS316L | |

| 4) SPTE, galvanized sheet | |

| 5) Brass, copper | |

| 6) ABS, PP, PE, PC, POM | |

| Surface Treatment | Anodized, powder coating, lacquer coating, black oxide, printing, matte, glossy, textured |

| Size | 1) According to customers' drawings |

| 2) According to customers' samples | |

| Drawing Format | step, dwg, igs, pdf |

| Payment Term | T/T, L/C, Trade Assurance |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Bicycle Gear Systems

Reason: CNC machined aluminum parts are ideal for bicycle gear systems due to their lightweight and durability, enhancing performance and reducing wear during continuous use.

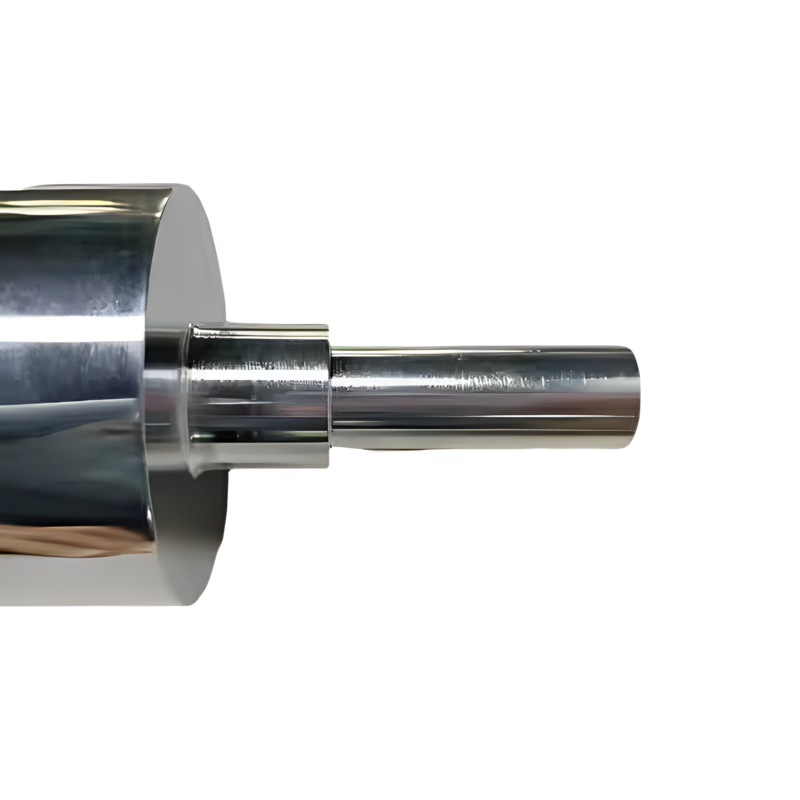

Spindles in Industrial Machinery

Reason: Aluminum CNC parts are used in spindles for industrial machines because of their high precision and strength, ensuring efficient and reliable machine operation.

Drone Components

Reason: Drones utilize CNC machined aluminum parts in their frames and joints for their lightweight, strength, and resistance to vibrations, ensuring stable flight and long-lasting performance.

Material

Aluminum Alloy

Stainless Steel

Copper

Quality Control

Quality control for Precision CNC Turned Aluminum Parts involves thorough inspections at every stage of production to ensure the highest standards of accuracy, durability, and reliability. Advanced measuring tools, such as coordinate measuring machines (CMM), are used to verify dimensional precision and tolerances. Surface finish is meticulously checked to meet specific design and functional requirements. Material integrity is assessed to ensure consistency and eliminate defects, while rigorous functional testing ensures that each part performs as intended

Processing capability

Quality control for Processing Capability ensures that every step of the manufacturing process delivers components with exceptional precision, durability, and performance. Advanced inspection tools, such as coordinate measuring machines (CMM) and optical scanners, are used to verify dimensional accuracy and tolerances. Material quality is assessed to maintain consistency and eliminate defects, while machining parameters are closely monitored to optimize efficiency and precision.

Additional processes

Additional processes for Precision CNC Turned Aluminum Parts include surface treatments such as anodizing, polishing, or sandblasting to enhance appearance, durability, and corrosion resistance. Heat treatment can be applied to improve the material's mechanical properties, such as strength and hardness. Deburring is performed to ensure smooth edges and eliminate imperfections, while threading or tapping adds functionality for assembly purposes.