Product Description

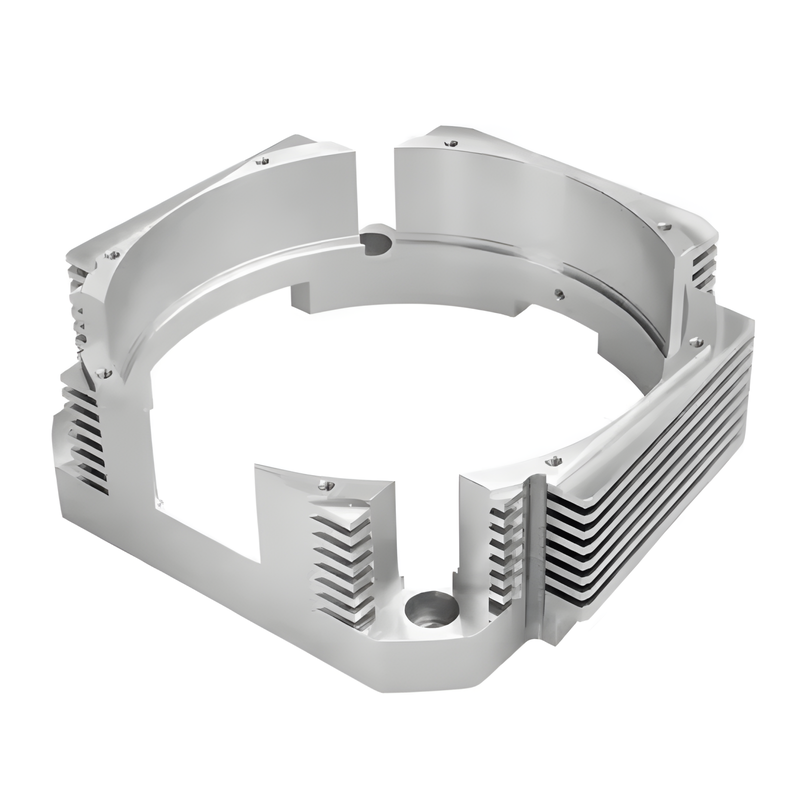

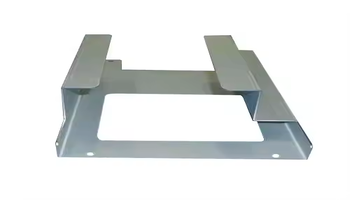

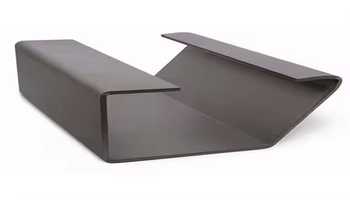

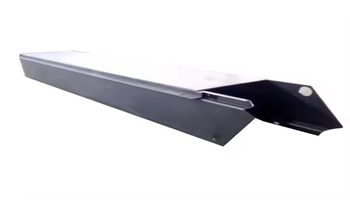

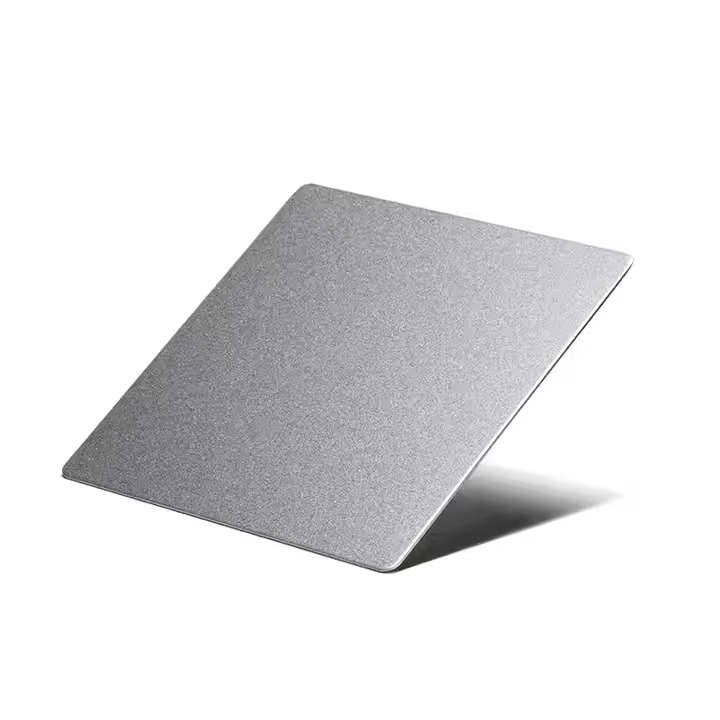

Custom professional aluminum parts are precision-engineered components designed to meet specific industrial requirements. Crafted from high-quality aluminum, these parts offer excellent strength-to-weight ratio, corrosion resistance, and durability. Tailored to exact specifications, they are ideal for applications in industries such as aerospace, automotive, and manufacturing. Our custom aluminum parts are produced using advanced machining, cutting, and finishing techniques to ensure precise dimensions and optimal performance. Whether for complex designs or standard applications, these parts provide a reliable solution for various professional uses. We prioritize quality and precision to deliver products that exceed customer expectations.

Product parameters

| List | Details |

|---|---|

| Product name | CNC Machine Parts |

| Material Capabilities | Precious Metals |

| Type | Other Machining Services |

| Materials Avaliable | Hardened Metals |

| Process | Cnc Machining+deburrs |

| Surface treatment | Painting |

| Equipment | CNC Machining Centres |

| Material | Brass |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

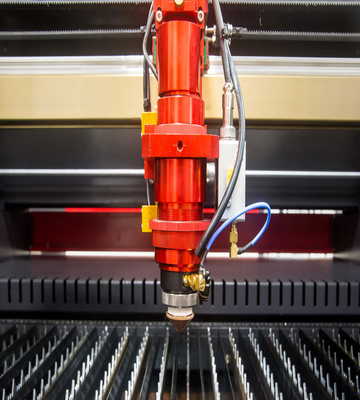

Laser Cutting

Milling & Drilling

Turning

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

The quality control (QC) of custom professional aluminum parts ensures each component meets the highest standards of precision and performance. We conduct thorough inspections throughout the production process, verifying dimensional accuracy, surface finish, and structural integrity. Advanced measurement tools, including CMM (Coordinate Measuring Machines), are used to check tolerances and ensure consistency. We also perform material testing to verify strength, corrosion resistance, and durability. Any deviations are promptly identified and corrected. Our QC process guarantees that every custom aluminum part delivers reliable, long-lasting performance in its intended application.

Processing capability

The processing capability of custom professional aluminum parts combines advanced techniques to produce precise and high-performance components. We utilize state-of-the-art CNC machining, including milling, turning, and drilling, to achieve exact dimensions and intricate designs. Our aluminum parts can be fabricated from various grades, offering excellent strength, lightweight properties, and superior corrosion resistance, ideal for industries like aerospace, automotive, and electronics.

Additional processes

We also offer precision cutting, including laser cutting and waterjet cutting, for clean and accurate edges. After cutting, the parts are processed through bending, welding, and assembly as required to meet specific project needs. Surface finishing techniques, such as anodizing, powder coating, and polishing, are applied to enhance both aesthetics and durability.

With a focus on custom designs, we ensure parts meet tight tolerances and complex geometries, delivering parts that perform efficiently under demanding conditions. Our advanced processing capabilities ensure every aluminum part is crafted to the highest standards for quality, functionality, and reliability.