Product Description

Custom CNC steel alloy machining services providing precise milling and turning solutions, tailored to your specifications for high-quality, durable, and reliable parts. Our advanced CNC technology ensures tight tolerances and exceptional surface finishes, delivering components that excel in both performance and appearance. From prototyping to high-volume production, we cater to diverse industries such as automotive, aerospace, industrial machinery, and robotics. Each part undergoes rigorous quality control to meet the highest industry standards, ensuring consistent results.

Product parameters

| Process | CNC Turning Miling |

| Logo | Accept Custom Logo |

| OEM/ODM | Accecpted |

| Sample | Samples Offered |

| Packaging Details | The carton for outer packing the inner packaging according to customer's requirement |

| CNC Manufacturer Machining Stainless Steel Mechanical Engineering Components | |

| Drawing Format | PDF;DWG;STEP;IGES |

| Surface treatment | N/A;Polished;As Custom |

| Keyword | mechanical engineering components |

| Delivery Time | 14 days;21 days;30 days |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

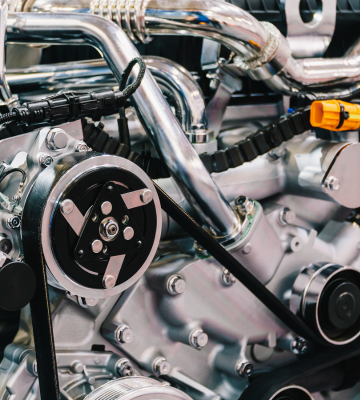

Automotive Engine Components

Reason: CNC-machined steel alloy parts are ideal for automotive engine components, such as pistons and crankshafts, due to their strength, durability, and ability to withstand high temperatures and pressures. These parts ensure smooth engine operation and long-lasting performance.

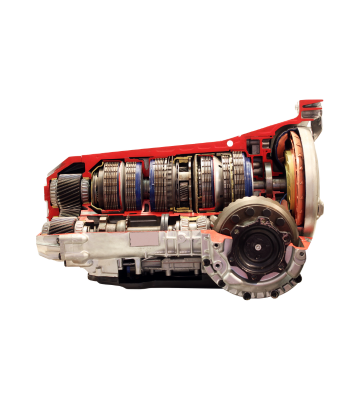

Industrial Gearboxes

Reason: CNC steel alloy parts are commonly used in gearboxes for heavy machinery. Their superior hardness and wear resistance make them perfect for handling the high stresses and constant motion within gear systems, ensuring reliability and minimal downtime.

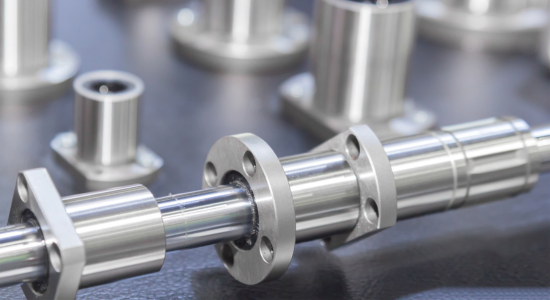

Machine Tool Spindles

Reason: CNC steel alloy components are used in machine tool spindles because of their ability to handle high rotational speeds and heavy loads. These parts maintain precise performance under stress, ensuring the reliability and accuracy required in manufacturing processes.

Material

Aluminum Alloy

Stainless Steel

Copper

Quality Control

Quality control for Custom CNC Steel Alloy Machining Services ensures that every part produced meets stringent specifications for precision, durability, and performance. Throughout the machining process, advanced tools like coordinate measuring machines (CMM) are used to verify dimensional accuracy and tight tolerances. Material quality is rigorously inspected to ensure uniformity and integrity, eliminating any defects.

Processing capability

The processing capability of Custom CNC Steel Alloy Machining Services includes advanced machining techniques such as turning, milling, drilling, and grinding to produce complex and high-precision components. With the ability to work with a wide range of steel alloys, these services can handle various part sizes and geometries, from small intricate designs to large, robust components. CNC machines provide exceptional precision, tight tolerances, and smooth surface finishes, ensuring that each part meets the required specifications.

Additional processes

Additional processes for Custom CNC Steel Alloy Machining Services include surface treatments such as heat treatment to enhance material strength and hardness, as well as coating processes like anodizing or powder coating for added corrosion resistance. Deburring ensures smooth edges and eliminates sharp points, while threading, tapping, and drilling add functional features for assembly or integration. Polishing or surface grinding may be applied to achieve a desired finish, improving both appearance and performance.