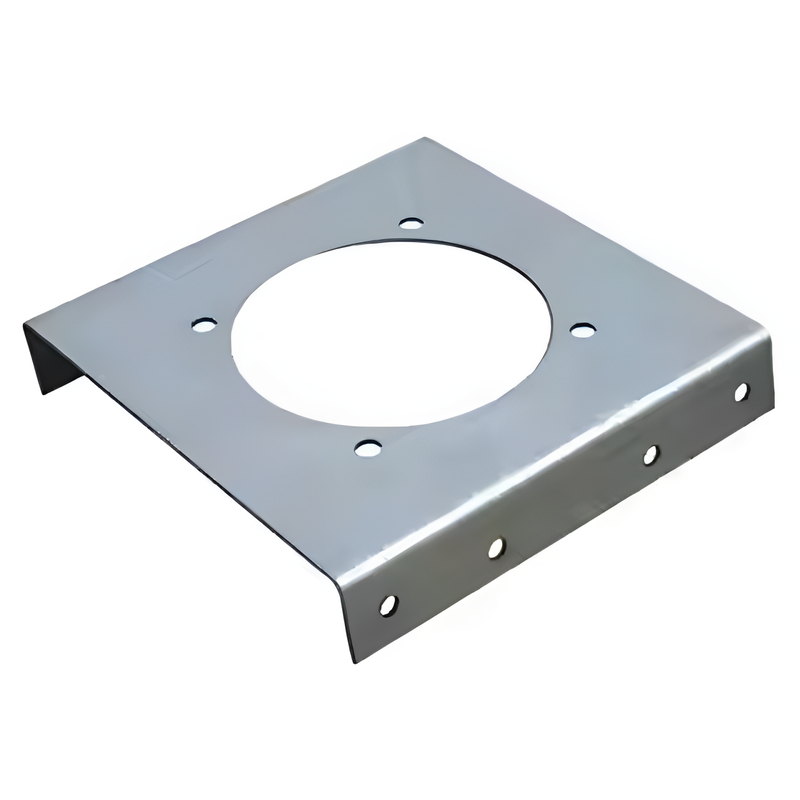

Product Description

Stamped Parts: High-precision metal components crafted through advanced stamping processes, designed to meet the exacting standards of durability, reliability, and performance. These versatile components are tailored for use across diverse industries, including automotive, electronics, construction, and manufacturing.

Product parameters

| Product Name | Stamped Parts | |||

| Services | Customized OEM ODM | |||

| Delivery Time | According Customers | |||

| Material | Customized | |||

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Automotive Body Panels

Reason: Parts used in vehicle bodies, such as doors, hoods, and roofs, are crafted through stamping processes to achieve strength and durability, ensuring the vehicle's safety and performance.

Electronic Connectors

Reason: Connectors in electronic devices, such as computers or smartphones, use highly precise stamped parts to ensure stable connections and long-lasting performance.

Home Appliance Parts

Reason: Parts in home appliances, such as refrigerators, washing machines, or microwaves, are stamped to create durable components that can withstand impacts, increasing the lifespan of the appliances.

Material

Aluminum Alloy

Stainless Stee

Copper

Quality Control

Quality control of stamped parts ensures that every component meets strict standards for precision, durability, and functionality. The process involves thorough inspection at various stages, from raw material selection to final product testing. Dimensional accuracy is verified through advanced measurement tools, while strength and durability are assessed through rigorous testing, including stress, fatigue, and impact tests.

Processing capability

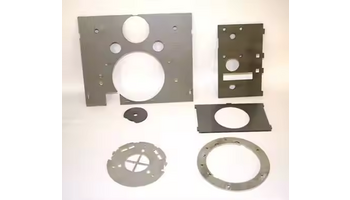

The processing capability of stamped parts involves a range of advanced techniques that enable the production of high-precision components from various materials, such as steel, aluminum, and copper. The stamping process includes operations like blanking, punching, bending, and embossing, which are tailored to achieve complex shapes and tight tolerances.

Additional processes

Additional processes for stamped parts include operations such as welding, coating, and assembly, which enhance the functionality and performance of the components. After the stamping process, parts can undergo welding to join multiple pieces together or create more complex structures. Coatings, such as powder coating or electroplating, are applied to improve corrosion resistance, aesthetic appearance, or provide electrical conductivity.