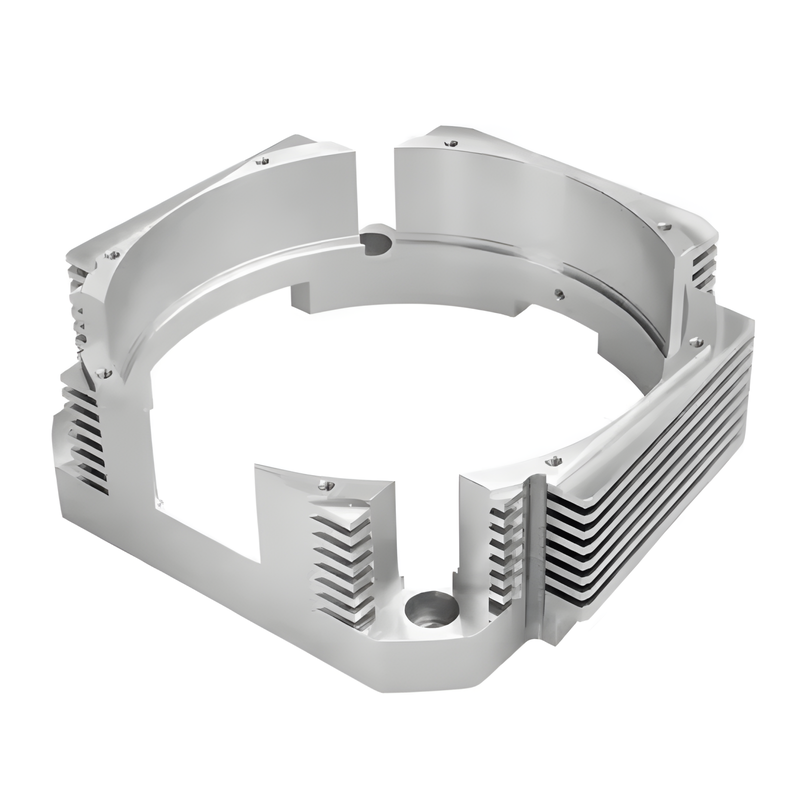

Product Description

This High Precision Anodized Aluminum is designed for superior durability and performance, featuring a corrosion-resistant anodized finish that enhances its longevity. With a high degree of accuracy in manufacturing, it ensures consistent dimensional precision and minimal tolerance. Ideal for applications in aerospace, automotive, and electronics, it combines lightweight strength with excellent thermal conductivity. The anodized surface provides increased wear resistance and improved aesthetics. Available in various finishes and sizes, this product is perfect for both functional and aesthetic uses, offering an optimal balance of strength, performance, and style.

Product parameters

| List | Details |

|---|---|

| Product name | Custom CNC machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, stainless steel, Steel Alloys |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Keywords | Precision CNC milling processing |

| Material | Aluminum/brass/plastic/copper/titanium alloy |

| Equipment | Three-axis, four-axis, five-axis machining center |

| Process | CNC milling;CNC turning |

| Application | Industrial equipment |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

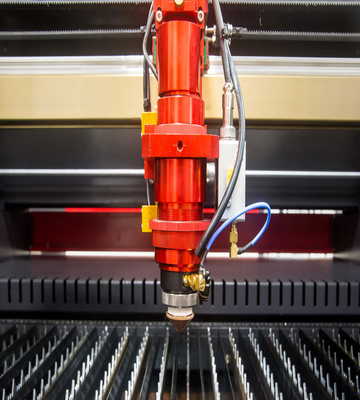

Laser Cutting

Milling & Drilling

Turning

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

The QC process for High Precision Anodized Aluminum ensures strict adherence to industry standards, focusing on dimensional accuracy, surface quality, and material integrity. Each batch undergoes comprehensive inspection for tolerances, ensuring minimal deviation from specifications. The anodized coating is thoroughly tested for thickness, uniformity, and adhesion to guarantee durability. A series of non-destructive tests are performed to check for defects such as cracks, scratches, or discoloration. Rigorous mechanical testing, including hardness and tensile strength, ensures the aluminum meets performance requirements. The final product undergoes visual inspection to confirm overall quality and finish consistency.

Processing capability

The processing capability of High Precision Anodized Aluminum includes advanced machining techniques, such as CNC milling, turning, and precision drilling, ensuring tight tolerances and complex geometries. The aluminum can be precisely shaped and cut to meet specific design requirements, while maintaining structural integrity. It undergoes a high-quality anodizing process, which enhances corrosion resistance, surface hardness, and aesthetic appeal. The anodized layer is controlled for uniformity, ensuring an even coating thickness.

Additional processes

In addition to standard machining, capabilities include laser engraving, surface polishing, and custom finishing to meet both functional and decorative needs. The material can be heat treated for improved strength and durability. Advanced quality control techniques are used throughout the entire process, from material selection to the final product, ensuring precise performance characteristics. The aluminum is compatible with a wide range of industries, including aerospace, automotive, electronics, and medical, where high tolerance and finish are essential. Furthermore, custom anodizing colors and finishes are available to cater to specific aesthetic preferences.