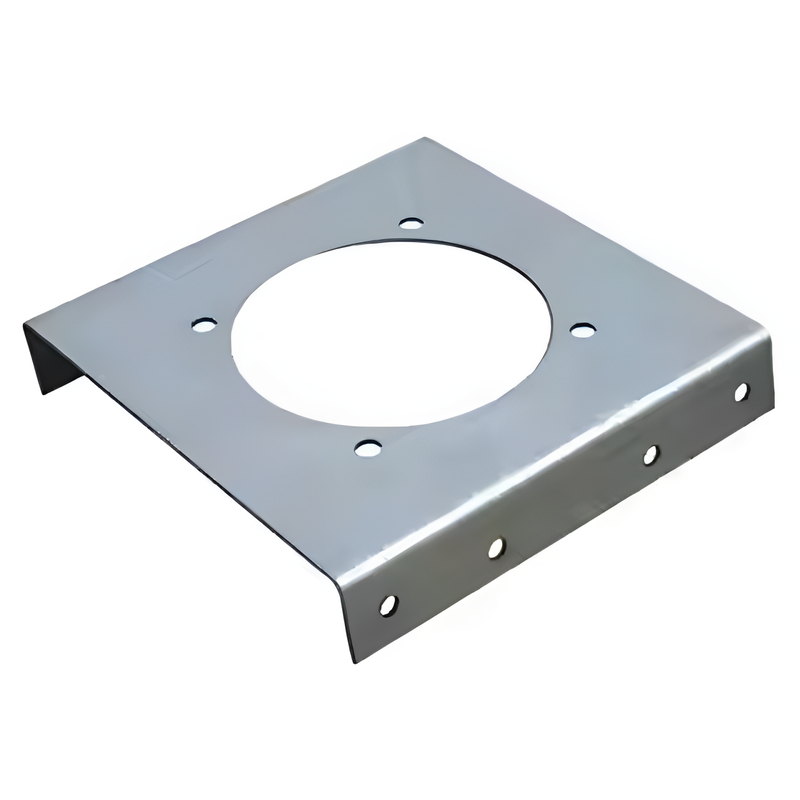

Product Description

Precision Craft Auto Components: High-quality custom metal parts, including stainless steel, iron, and copper, expertly crafted for automotive and industrial applications. Our components are designed with precision to meet the stringent demands of various industries, ensuring superior performance and durability. We utilize state-of-the-art manufacturing processes, including advanced stamping, CNC machining, and welding, to produce parts that fit perfectly and function reliably.

Product parameters

| Material | Steel |

| Application | Industry |

| Service | Customize ODM, OEM |

| Color | Customized Color |

| Size | Customer's Drawings |

| Logo | Accept Customized Logo |

Custom Process

1.send inquiries

2.drawings or samplet

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

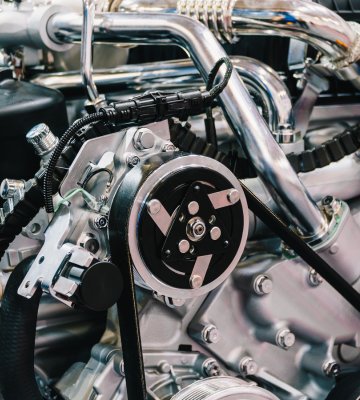

Engine Components

Reason: Engine parts such as crankshafts and pistons use Precision Craft Auto Components for high precision in manufacturing and durability under high heat and pressure.

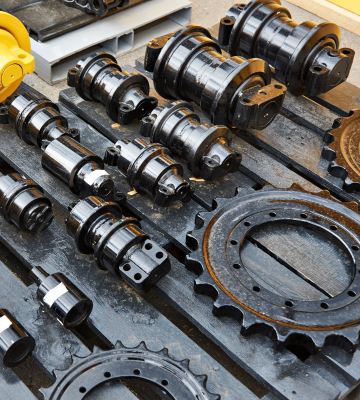

Chassis Parts

Reason: Vehicle structural components, such as bumpers or suspension arms, use parts made from steel and stainless steel to ensure strength and resistance to impacts and wear.

Transmission Components

Reason: Parts in the transmission system, such as bearings and gears, require high precision and durability to withstand forces and high rotational speeds, making high-quality components essential.

Material

Stainless Stee

Aluminum Alloy

Copper

Quality Control

Quality control of Precision Craft Auto Components is a comprehensive process that ensures each part meets the highest standards of precision, durability, and performance. The process starts with thorough inspection of raw materials, ensuring that they meet the required specifications before manufacturing begins. During production, each component undergoes rigorous checks for dimensional accuracy using advanced measurement tools, while strength and endurance are tested through various mechanical tests.

Processing capability

The processing capability of Precision Craft Auto Components involves a range of advanced manufacturing techniques designed to produce high-quality, custom metal parts. Using state-of-the-art equipment such as CNC machines, stamping presses, and welding systems, the process enables the creation of intricate and precise components from materials like steel, stainless steel, and copper.

Additional processes

Additional processes for Precision Craft Auto Components include various secondary operations designed to enhance the functionality, quality, and performance of the parts. After the initial manufacturing, components may undergo processes such as heat treatment to improve strength and hardness, surface coating for corrosion resistance or aesthetic appeal, and assembly for integrating multiple parts into a final product. Further operations like drilling, tapping, and finishing ensure the parts meet specific design requirements, while custom packaging and labeling are offered to facilitate handling and delivery.