Product Description

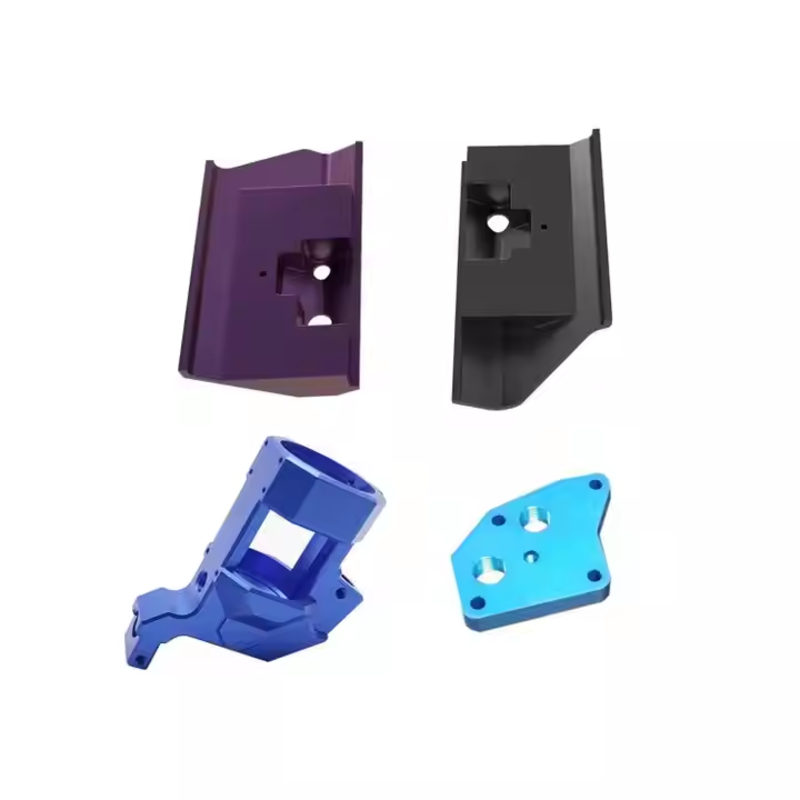

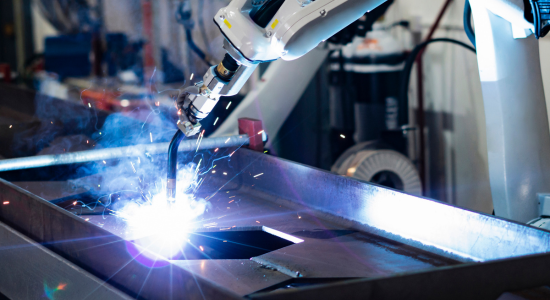

Our Aluminum CNC Machining Services offer high-precision, custom-machined parts tailored to your specifications. Utilizing advanced CNC technology, we ensure tight tolerances and complex geometries with exceptional accuracy. We work with a variety of aluminum grades, providing lightweight yet strong solutions for industries such as aerospace, automotive, and electronics. Our services include milling, turning, drilling, and finishing, delivering high-quality parts with smooth surfaces and superior durability. With quick turnaround times and scalable production, we meet both small and large volume demands. Whether for prototypes or production runs, our aluminum machining services guarantee reliability and performance.

Product parameters

| List | Details |

|---|---|

| Product name | Custom CNC machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, stainless steel, Steel Alloys |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Keywords | Precision CNC milling processing |

| Material | Aluminum/brass/plastic/copper/titanium alloy |

| Equipment | Three-axis, four-axis, five-axis machining center |

| Process | CNC milling;CNC turning |

| Application | Industrial equipment |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Drilling

Milling

Turning

Material

Silver

Brass

Copper

Quality Control

Our QC process for Aluminum CNC Machining Services ensures the highest standards of precision and quality. Each part undergoes detailed dimensional inspections to confirm tight tolerances and accurate geometries. Advanced measuring tools, such as CMM (Coordinate Measuring Machines), are used to verify the accuracy of each component. Surface finish and material integrity are thoroughly checked to meet industry specifications. All parts are tested for consistency and durability through non-destructive methods. The final product undergoes a visual inspection to ensure it meets both functional and aesthetic requirements.

Processing capability

Our Aluminum CNC Machining Services offer extensive processing capabilities to meet diverse manufacturing needs. We utilize state-of-the-art CNC milling, turning, and drilling equipment, allowing us to create highly detailed and complex parts with tight tolerances. Our services cater to a variety of aluminum grades, ensuring both lightweight and strong components for a range of applications. We can handle intricate geometries, from simple to complex shapes, with precision and consistency.

We also provide custom finishing options, including surface polishing, anodizing, and powder coating, to enhance both the aesthetics and durability of the parts. Additionally, we offer thread tapping, chamfering, and deburring services to ensure the final product is ready for assembly.

Additional processes

Our capabilities extend to rapid prototyping, allowing quick turnaround for design validation before mass production.

With advanced CAD/CAM software integration, we can optimize machining processes for efficiency and accuracy. Our experienced team ensures that all parts meet the highest quality standards, with detailed inspections at every stage of production. Whether for one-off prototypes or high-volume runs, we offer scalable solutions for industries such as aerospace, automotive, and electronics.