Product Description

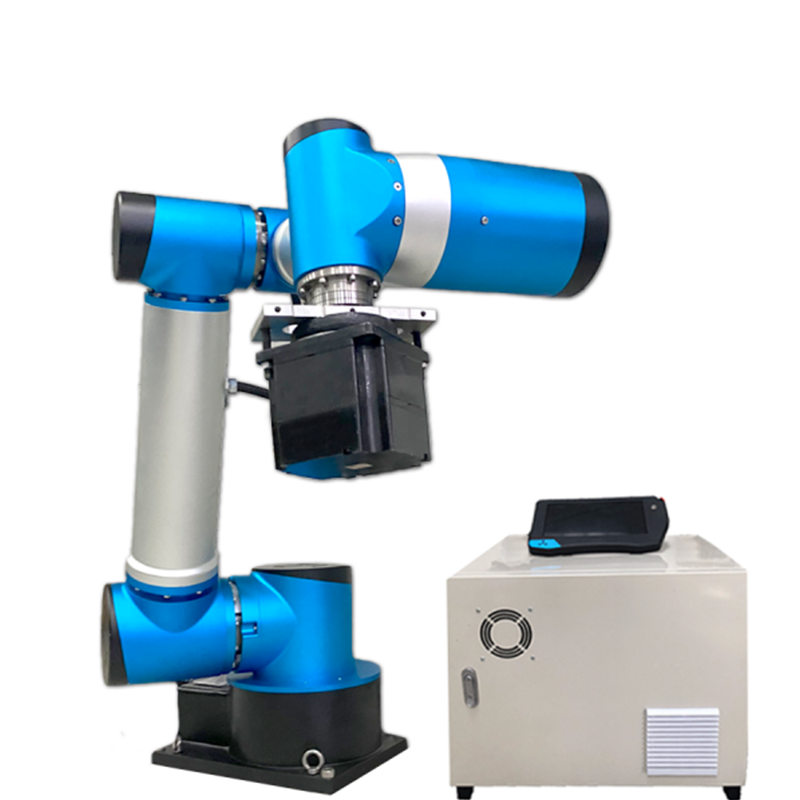

The VJ collaborative robot joint features high flexibility in its transmission system, allowing for adjustments and compatibility with various types of cobots and different applications. It provides diverse compatibility and easy integration into existing automation systems.

Product parameters

| Model | VJ-01 | VJ-02 | VJ-03 | VJ-04 | |||||||||

| Ratio | 14-50 | 14-80 | 14-100 | 17-50 | 17-80 | 17-100 | 20-50 | 20-80 | 20-100 | 25-50 | 25-80 | 25-100 | 25-120 |

| Output peak speed(RPM) | 60 | 37.5 | 30 | 60 | 37.5 | 30 | 60 | 37.5 | 30 | 60 | 37.5 | 30 | 25 |

| Rated torque(Nm) | 22.8 | 36.5 | 45.6 | 37.6 | 60.16 | 90.24 | 58 | 92.8 | 116 | 70.4 | 112.6 | 140.8 | 169 |

| Peak torque(Nm) | 65.2 | 104.3 | 130.4 | 107.2 | 171.5 | 257.3 | 164 | 262.4 | 328 | 198 | 316.8 | 396 | 475.2 |

| Motor watt(W) | 100 | 200 | 400 | 750 | |||||||||

| Voltage(V) | 48 ( +/- 10%) | ||||||||||||

| Rated current(A) | 3.5 | 6.5 | 10.5 | 17 | |||||||||

| Peak current(A) | 15 | 19 | 29 | 48 | |||||||||

| Output encoder resolution | 20 Bits | ||||||||||||

| Repeat positioning accuracy(degrees) | +/- 0.0025 | ||||||||||||

| Communication bus | EtherCAT/ CANopen | ||||||||||||

| Outer diameter x length x through hole (mm) | 75 x 101 x 10 | 95 x 106 x 12 | 105 x 108 x 14 | 110 x 128 x 16 | |||||||||

| Weight (kg) | 1 | 1.4 | 2.5 | 3.3 | |||||||||

| Brake | Friction damping brake | ||||||||||||

| IP rating | IP54 | ||||||||||||

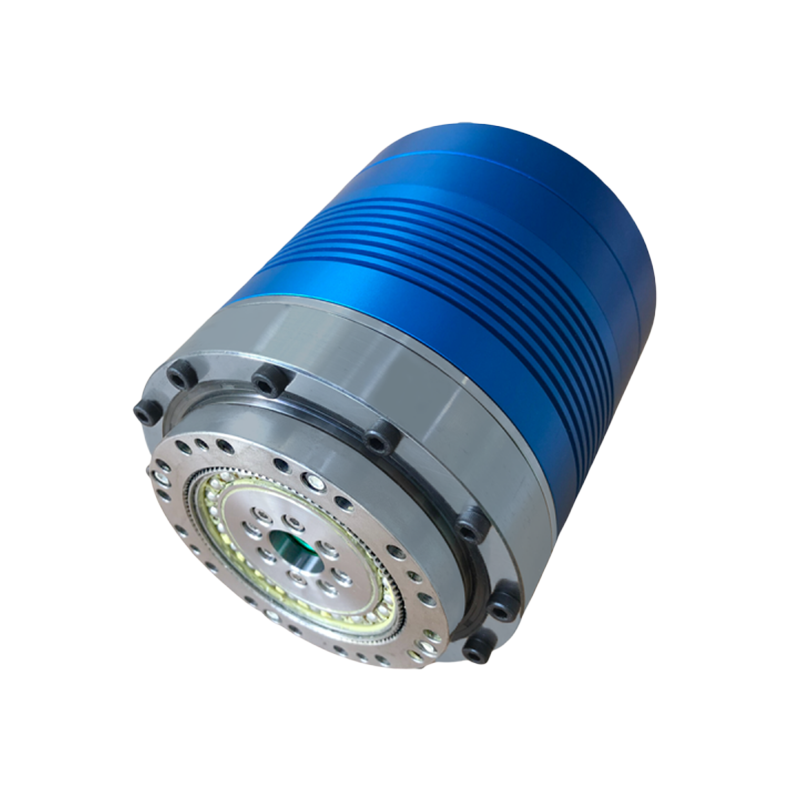

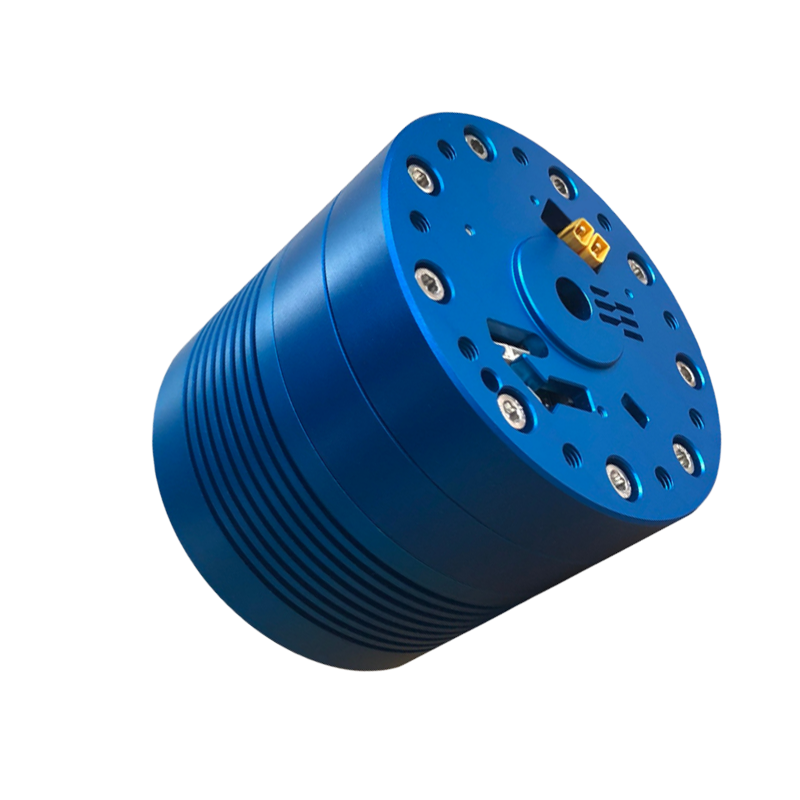

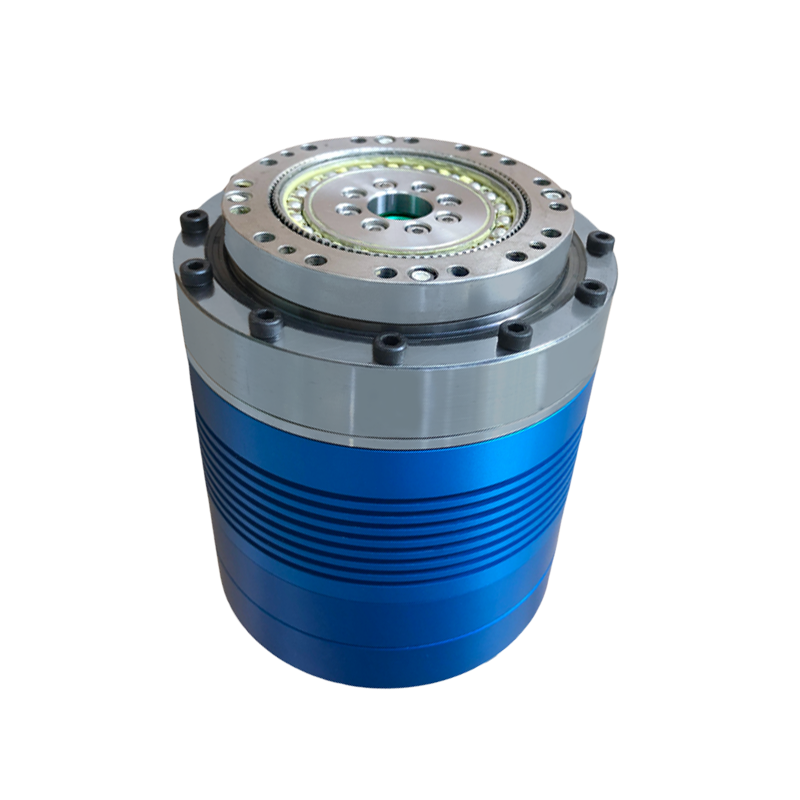

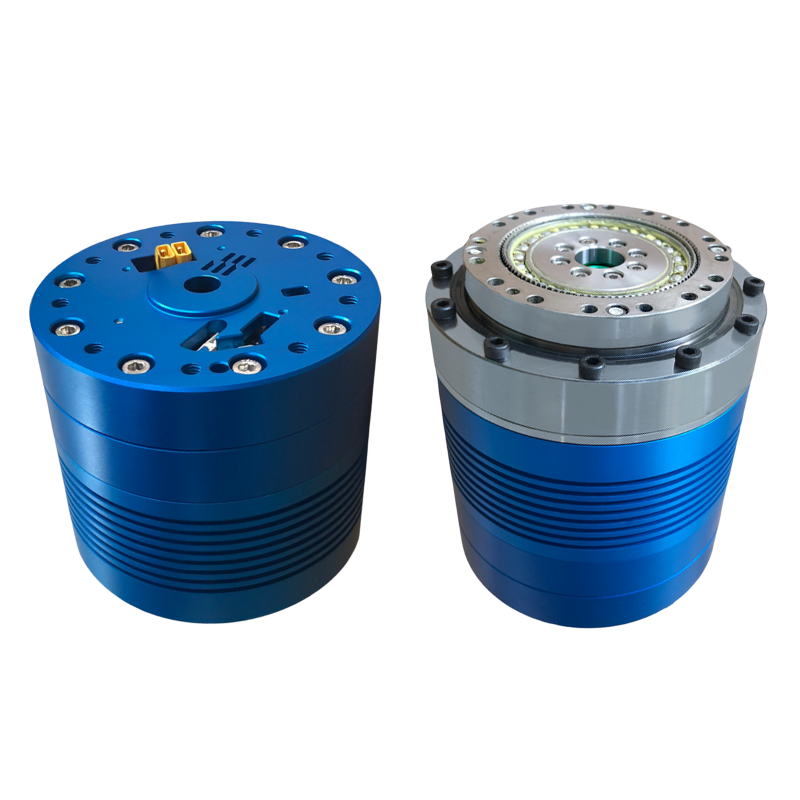

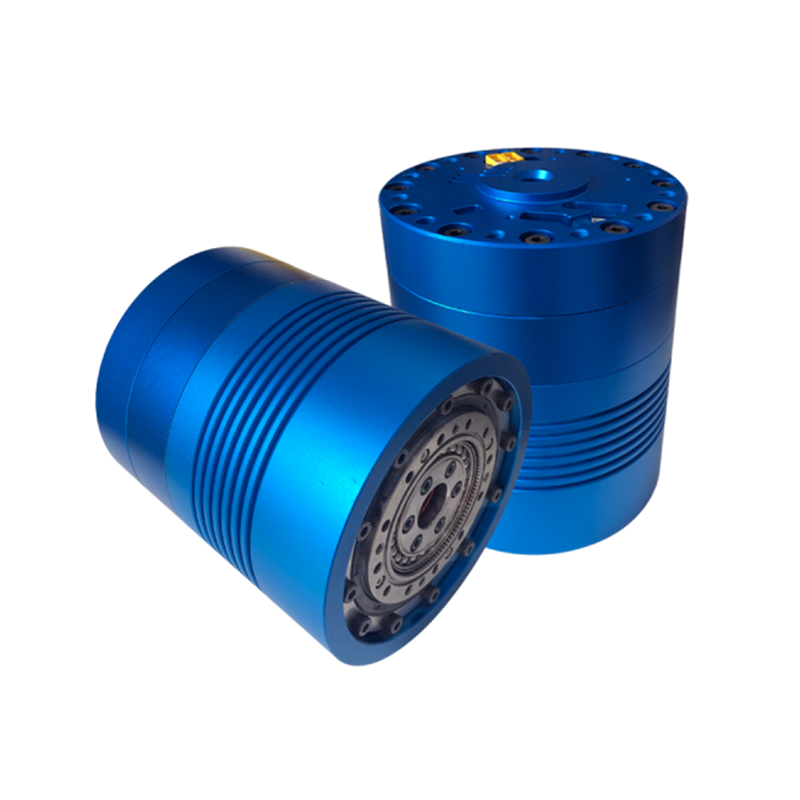

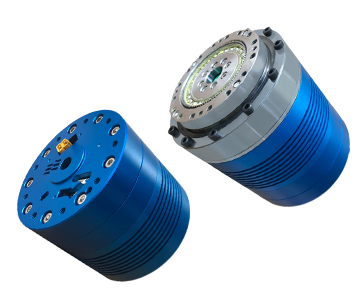

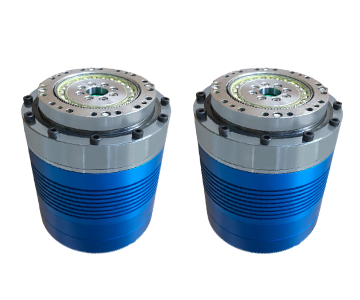

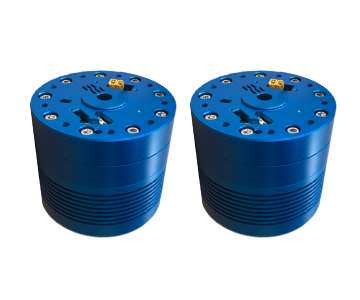

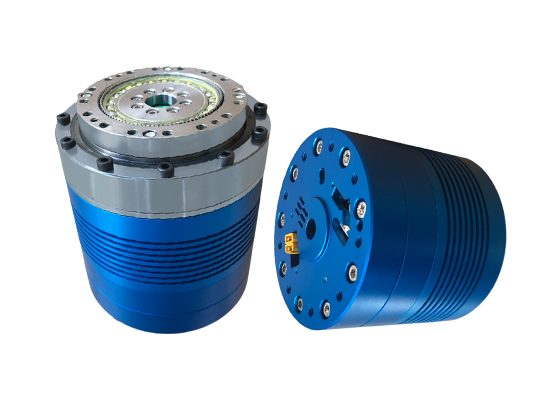

Product Display

- 3- phase Field Oriented Control (FOC)

- Absolute encoder (20 bits at motor)

- High resolution current sampling

- Flux weakening algorithm

- Feed-Forward

- SVPWM generation (Centered PWM pattern type & Adjustable PWM frequency)

- Torque control mode, speed control mode & position control mode

- Brake strategies ( Motor phase short-circuiting)

- Real-time fine tuning of PID Regulators

- Fault management: Overcurrent, Overvoltage, Overtemperature, Speed feedback reliability error

- High Speed EtherCAT Slave ( 100 Mbps Full-Duplex)

- Terminal Debug Commands via UART

- Joint Collision Detection

- Self-diagnosis of joint damage

Application Cases

Super-large collaborative robot joints have key applications in many fields. In automobile manufacturing, it assists in car body assembly, accurately controls the robotic arm to carry heavy parts, ensures assembly accuracy, and improves production efficiency. In the logistics industry, it can flexibly drive the robotic arm to quickly sort goods, adapt to high-intensity and long-term operations, and reduce labor costs. In shipbuilding, it can control large tools for welding and grinding, and handle heavy steel plates with high load capacity to ensure process quality. At the same time, in the aerospace field, it accurately assists in the assembly of precision parts, empowers high-end manufacturing, and promotes industrial development to new heights.