Product Description

Our Custom Prototype CNC Machining services provide rapid, precise, and cost-effective solutions for turning design concepts into functional prototypes. Utilizing advanced CNC technology, we can quickly produce complex, high-precision parts with tight tolerances and intricate details. We work with a wide range of materials, including aluminum, steel, and plastics, to meet specific application requirements. From one-off prototypes to small batch runs, our services are tailored to support product development and design validation. With fast turnaround times and superior quality control, we ensure prototypes that meet both functional and aesthetic specifications. This service is ideal for industries such as automotive, aerospace, and consumer electronics.

Product parameters

| List | Details |

|---|---|

| Product name | Custom CNC machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, stainless steel, Steel Alloys |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Keywords | Precision CNC milling processing |

| Material | Aluminum/brass/plastic/copper/titanium alloy |

| Equipment | Three-axis, four-axis, five-axis machining center |

| Process | CNC milling;CNC turning |

| Application | Industrial equipment |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Drilling

Milling

Turning

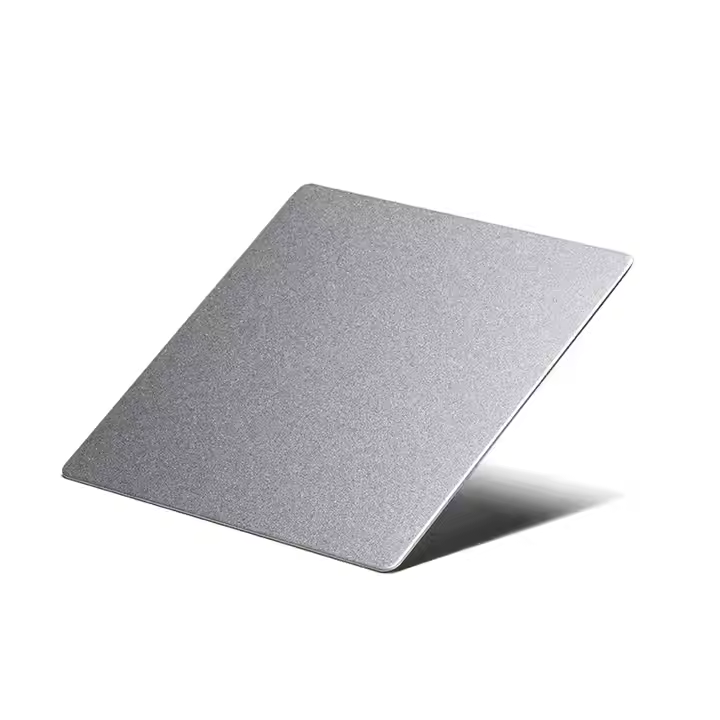

Material

Silver

Brass

Copper

Quality Control

Our QC process for Custom Prototype CNC Machining ensures the highest levels of precision and quality. Each prototype undergoes comprehensive dimensional inspection to confirm adherence to design specifications and tight tolerances. Advanced measuring tools, such as CMM (Coordinate Measuring Machines), are used to ensure accuracy and consistency. Surface finish, material integrity, and overall part functionality are closely monitored throughout the process. We perform non-destructive testing to identify any potential defects. Finally, each prototype is visually inspected to meet both functional requirements and aesthetic expectations before delivery.

Processing capability

Our Custom Prototype CNC Machining services offer advanced capabilities for producing high-precision, intricate parts tailored to your design specifications. Utilizing state-of-the-art CNC milling, turning, and drilling equipment, we can achieve tight tolerances and complex geometries across a wide range of materials, including metals, plastics, and composites. Our machining processes allow for rapid prototyping, enabling quick iteration and testing of your design concepts.

We offer a variety of secondary operations, such as threading, chamfering, and polishing, to meet specific functional and aesthetic needs. Our team uses advanced CAD/CAM software to optimize tool paths, ensuring efficiency and accuracy in every part produced.

Additional processes

We are capable of producing both simple and highly detailed components, with the flexibility to handle low to medium-volume production.

From functional prototypes to pre-production parts, we focus on delivering high-quality results with minimal lead times. We can also integrate advanced finishing techniques like anodizing, powder coating, and heat treatment for added durability and performance. With a focus on innovation and quality control, we support industries like aerospace, automotive, medical, and consumer electronics in bringing their designs to life.