Product Description

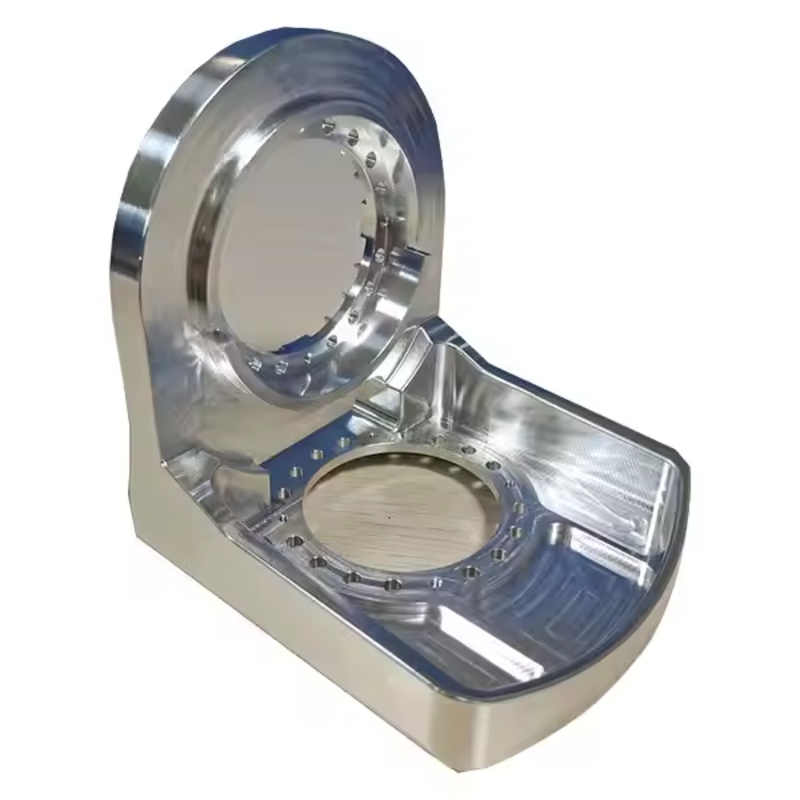

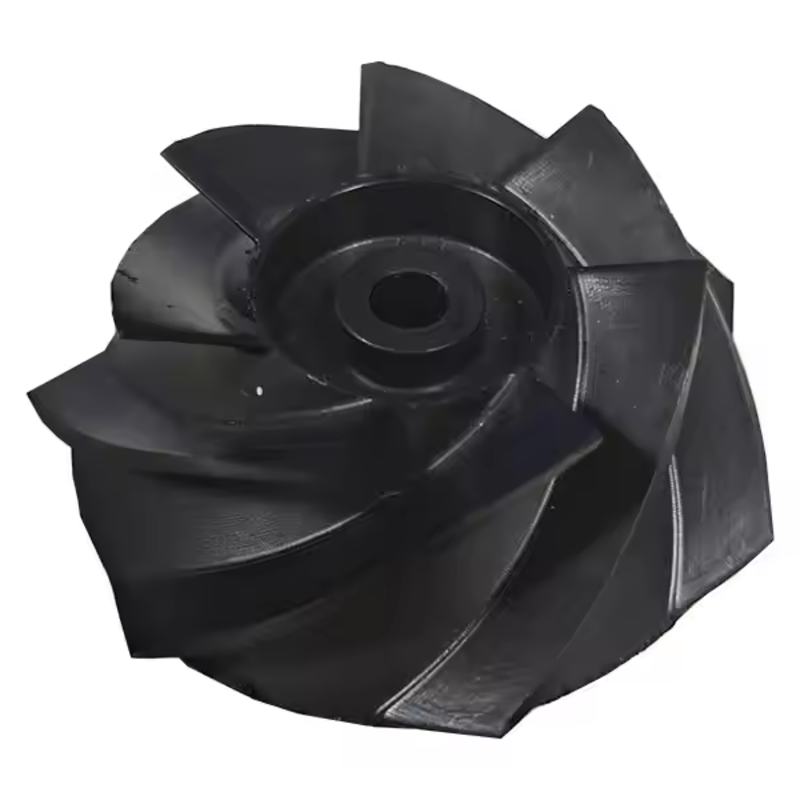

Our Keyboard CNC Machining services offer precision manufacturing for custom keyboard components, ensuring high-quality and durable parts. Using advanced CNC technology, we produce keycaps, housings, and other intricate components with tight tolerances and smooth finishes. Our team works with a variety of materials, including aluminum, stainless steel, and plastics, to meet your design requirements. Whether it's for mechanical, membrane, or custom keyboard designs, we ensure consistent quality and optimal performance. We provide both prototyping and large-scale production capabilities. Trust us for reliable, high-precision keyboard parts with quick turnaround times and superior craftsmanship.

Product parameters

| List | Details |

|---|---|

| Brand Name | Keyboard Cnc Machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, stainless steel, Steel Alloys, varirous plastic |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Material | ALUMINUM 6061 |

| Surface finish | Andized |

| Processing method | CNC MILLING |

| Color | various color |

| OEM/ODM | OEM ODM CNC Milling Turning Machining Service |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

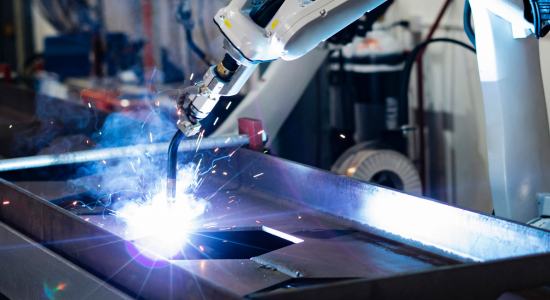

Milling & Drilling

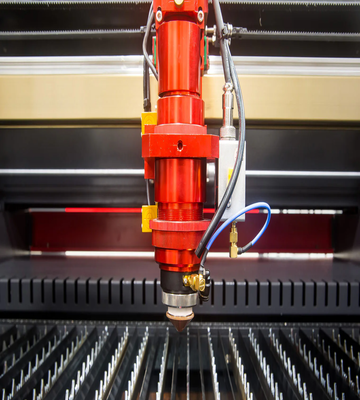

Laser Cutting

Turning

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

Our Quality Control (QC) for Keyboard CNC Machining ensures precise and reliable components for every project. We perform detailed inspections at each stage, from raw material sourcing to final product finishing. Using advanced measurement tools, we check key dimensions, tolerances, and surface finishes to guarantee accuracy. Visual inspections are conducted to detect any defects or imperfections in the components. We also test the functionality and durability of parts to ensure they meet performance standards. With a commitment to excellence, our QC process ensures the production of high-quality, defect-free keyboard parts.

Processing capability

Our Keyboard CNC Machining services offer a comprehensive range of capabilities to produce high-precision components for custom keyboards. We utilize state-of-the-art CNC machines for milling, turning, and engraving, allowing us to create intricate keycaps, housings, and other components with tight tolerances and excellent finishes. Our advanced machining techniques enable us to work with various materials such as aluminum, stainless steel, brass, and high-quality plastics like ABS, PBT, and polycarbonate.

Additional processes

We offer customization options such as different textures, surface finishes (e.g., anodizing, powder coating, and polishing), and engraving or laser etching for unique designs. Our machining process supports both small-scale prototypes and large-scale production runs. We also provide assembly and post-processing services, ensuring every component meets the highest quality standards. With precision capabilities for complex geometries and intricate detailing, we deliver durable and high-performance parts for mechanical, membrane, and custom keyboards. Our efficient production processes ensure fast turnaround times without compromising on quality.