Product Description

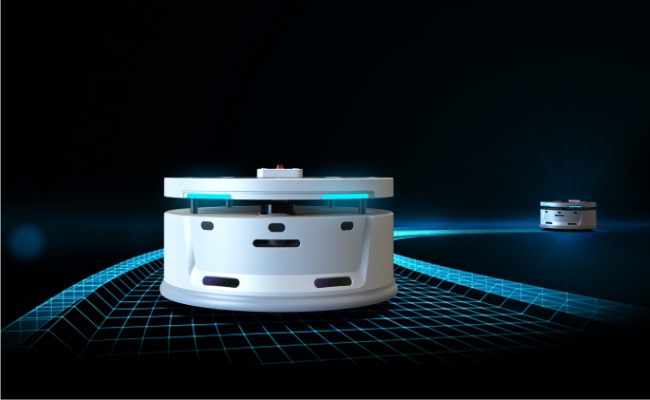

Apollo2.0 robot chassis new upgrade algorithm and hardware structure technology, based on the new SLAMWARE3.0 autonomous positioning and navigation system, multi-sensor fusion data to achieve high-precision positioning and navigation. Environmental adaptability, versatility, and durability are stronger, enabling the rapid development of full-scene applications and product landing.

Product Features

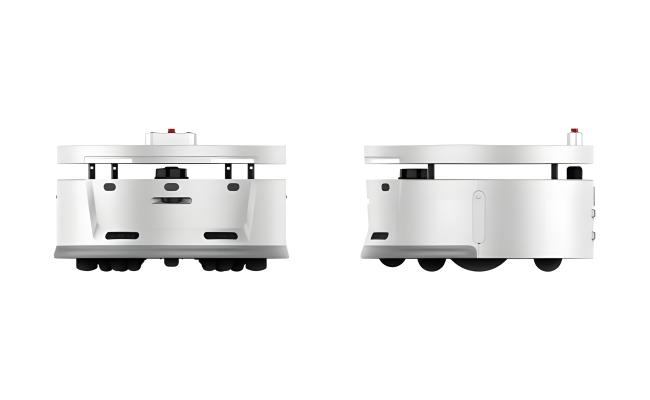

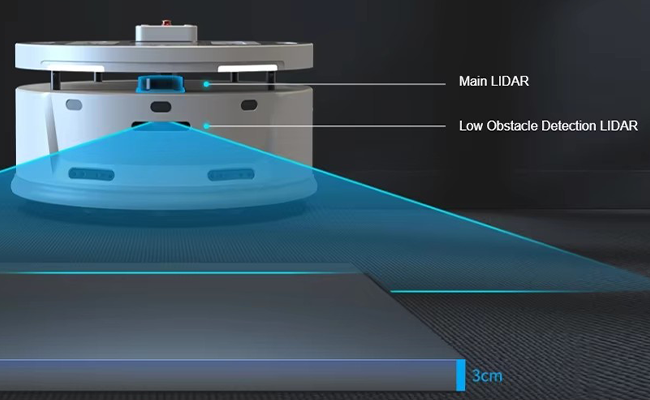

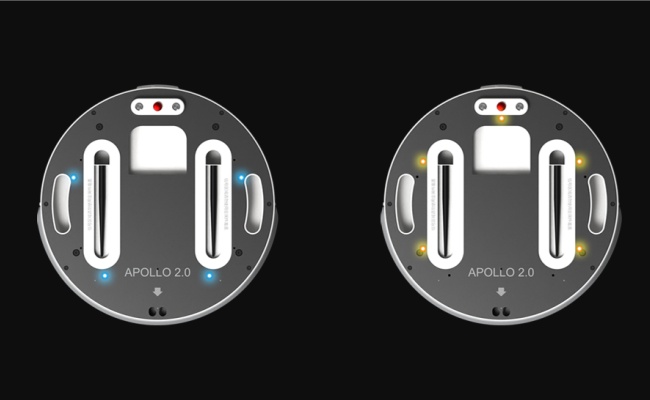

Multi-sensor fusion navigation, 360° no dead Angle protection

Equipped with and fusion of rich sensor data, high-precision mapping of large scenes. Accurately respond to static and dynamic obstacles and low obstacles to achieve stable and reliable positioning, navigation and obstacle avoidance.

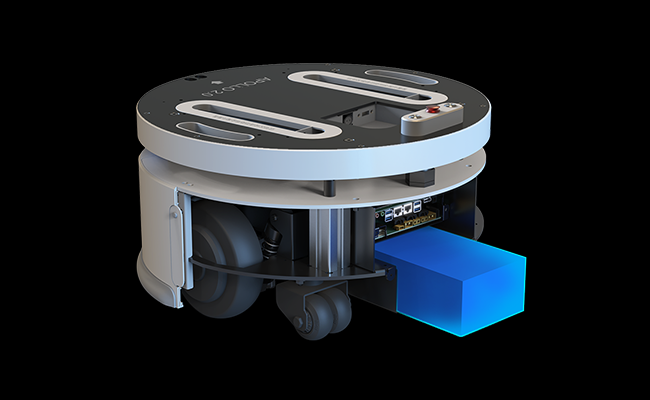

Strong athletic ability

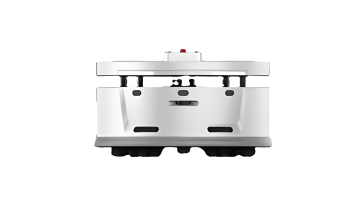

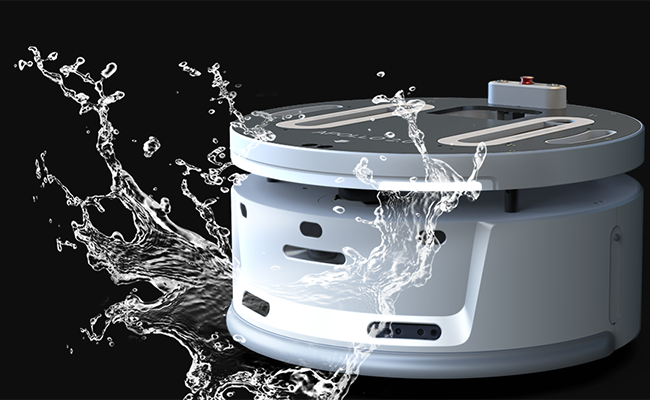

IP54 High protection level,

Water and dust proof.

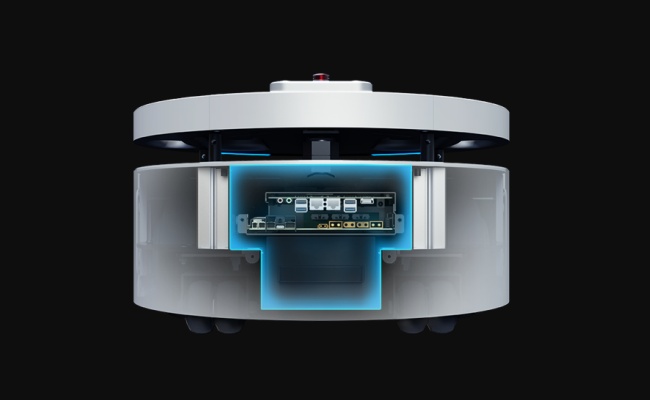

Enclosed bottom

Foreign body invasion is difficult,

Protect critical components.

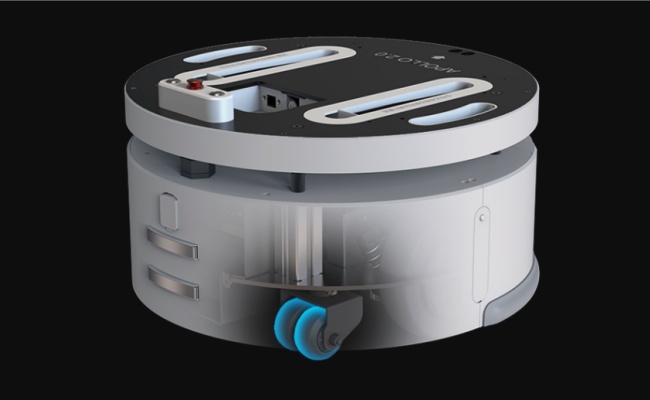

Double row industrial casters

Smooth and unimpeded

More stable operation in any direction

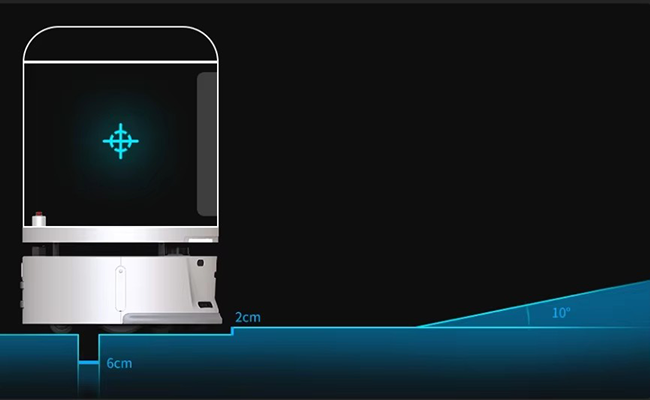

Strong ability to climb and overcome obstacles

2cm vertical pass

6cm horizontal gully

The machine climbs 10°

High integration

Compatible with chassis mounting holes on the market,

Bring convenient and efficient use experience.

High navigation accuracy and multiple modes

Apollo2.0 robot chassis is built with a variety of navigation modes, supporting accurate docking of the reflector, track direction customization, rolling travel log storage (black box), high-precision positioning, and more friendly experience.

15KV ESD protection, suitable for harsh environment

Apollo2.0 continues to optimize the fuselage materials, wire plug-ins and other hardware, air discharge 15KV, adapt to industrial harsh scenarios, harsh environment applications, performance is more stable.

Lithium iron phosphate battery

Apollo2.0 standard with lithium iron phosphate battery, to meet the stability, safety, large capacity, long life, long life and other needs. Support fast charging, line charging mode, improve the robot chassis work efficiency.

Application Cases

- Smart factory: The Internet of Things, automation and big data empowerment, optimize the production process, equipment operation and maintenance and supply chain, improve efficiency and competitiveness.

- Smart retail: Integrate online and offline, through smart devices and precision marketing, create convenient personalized shopping experience, and change the retail model.

- Smart hotels and restaurants: Use intelligent systems to optimize service processes, improve guest experience and operational efficiency, and enhance industry competitiveness.

- Intelligent inspection: Based on intelligent devices and data analysis, automatic inspection and hidden danger warning can ensure the safety and stability of various scenarios.

- Smart building: Rely on intelligent lighting, temperature control and other systems to create a comfortable and energy-saving space, reduce costs, and achieve intelligent management.

- Smart medical: integrates electronic medical records, telemedicine and other technologies to optimize processes and improve the quality of medical services and resource allocation efficiency.

Technical Parameter

| Machine name | Apollo Universal robotic platform | ||

|---|---|---|---|

| Core function | SLAM localization navigation | ||

| item | index | value | |

| Mass and volume | diameter | 520mm | |

| Chassis height | 270mm | ||

| Distance from ground | 28mm | ||

| Net weight | 40kg | ||

| Rated load | 80kg | ||

| Maximum load | 100KG(flat cement pavement) | ||

| Sensor performance parameter | Lidar sensor | quantity | one |

| Measuring radius | 0.05m-30m 90% reflectance 0.05m-10m 10% reflectance | ||

| Depth camera sensor | quantity | 2 | |

| Detection range | 0.186m~2m | ||

| Field of view (FOV) | H:147.3±3°;V:71.3±3° | ||

| Ultrasonic sensor | quantity | 3 | |

| Maximum detection range | 300cm | ||

| Low/cliff detection sensor | quantity | 1 | |

| Low minimum induction height | 3cm | ||

| Minimum inductive depth of cliff | 5cm | ||

| Magnetic sensor | quantity | 2 | |

| Maximum detection range | 3.5cm(disabled by default, enabled on demand) | ||

| Safe side contact | quantity | 1 | |

| Minimum induction force value | 10N | ||

| Mapping performance | Map resolution | 5cm/1.5cm | |

| Maximum area of a single construction plan | 500m x500m(5cm map resolution) 350mx350m(1.5cm map resolution) | ||

| Motion parameter | Maximum travel speed | 1.2m/s(1.5m/s can be customized) | |

| Default travel speed | 0.7m/s | ||

| Maximum travel speed in mapping mode | 0.6m/s | ||

| Maximum crossing grade | 10° ramp: the maximum slope Angle of the chassis is 10°, the slope is 18% ramp, and the machine's center of mass height is within 18cm Ramp within 10° (Slope 100% refers to 45° ramp, 100m length height difference is 100m) | ||

| Vertical overpass height | 2cm(rated load) | ||

| Width of horizontal overpass | 4cm(rated load) | ||

| Minimum pass width | 70cm | ||

| Point to point accuracy (AVG) typical value | +2cm(1.5cm map resolution)±4cm(5cm map resolution) | ||

| Point to point accuracy (MAX) Typical value | ±4cm(1.5cm map resolution) ±8cm(5cm map resolution) | ||

| Minimum arrival Angle | ±1.0° | ||

| Multi-machine obstacle avoidance | A maximum of three robots can be used in the same area | ||

| Electric machine | wheelset | 7NM 6.5-inch wheel motor *2 | |

| 2.5 inch industrial universal wheel *4; 2.5-inch training wheels *1(front) | |||

| User interface | Hardware interface | Customer power supply | DC 24V 10A {Support custom 20A+(with lithium iron phosphate battery)} |

| Power button | one | ||

| Scram button | one | ||

| Brake release button | one | ||

| Emergency charging interface | one | ||

| Network interface | Ethernet | 1*RJ45 Gigabit network port | |

| WIFI band | 2.4/5GHz | ||

| Software interface | SLAMWARET™ | SLAMWARE™: SDK2.0 http protocol API interface, can support different development languages and development platforms, Such as Windows/iOS/Android/Linux | |

| Battery and battery life | Capacity specification | 24V 29.4Ah(lithium iron phosphate battery) {Optional 35Ah ternary lithium battery} | |

| Duration of no-load operation | >16h | ||

| Full load duration | 14h | ||

| Charging time | 6h(Fast charging pile) | ||

| Battery life | After 2000 full discharge cycles, the charge drops to 80% of the initial capacity | ||

| Power dissipation | 待机额定功耗 | 25W | |

| Rated power consumption for full load operation (Full load 80kg) | 45W | ||

| Maximum power consumption of the external load | 280W | ||

| Autonomous return to charge | Dimensions of charging pile | 360mm*150mm*320mm | |

| Charging pile color | white | ||

| Rated input of charging pile | 100-240V 50/60Hz3A MAX | ||

| Rated output of charging pile | DC 25.5V 10A | ||

| Manual charging | support | ||

| noise | Working noise | ≤60dB | |

| Working environment | Operating temperature | 0℃~40℃ | |

| Working humidity | 20~90%rh | ||

| Service altitude range | ≤2000m | ||

| Transport and storage temperature | -25~+55℃ | ||

Product protection

Buy our robot chassis, you get not only high-quality products, but also a full range of protection services, use no worries.

We have a professional R & D team and perfect after-sales system, quality problems during the warranty period free repair or replacement, to ensure that the chassis is always the best operation. At the same time, provide detailed manuals and training materials to help you master operation and maintenance skills, customer service at any time to answer questions to give technical guidance to ensure smooth application.

We also keep up with industry trends, pay attention to customer feedback, continue to optimize and upgrade products, provide more advanced and reliable solutions, and strive to establish long-term cooperation with you to promote the development of robot technology and application innovation.

Customer Feedback

Hotel feedback

Guests have generally had a positive response to the hotel robots. Many guests praised the robot's efficient guidance during check-in, which saved time; Fast and accurate delivery of goods, late night urgent supplies can also be delivered in time, very intimate. Children especially enjoy interacting and playing with the robots to add joy to the journey.

Showroom feedback

Customer feedback on the showroom robot application is good. Most customers said that the robot explanation is clear and vivid, can quickly answer questions, greatly improve the efficiency and fun of the visit, and can accurately guide the tour route to avoid getting lost.

Medical feedback

The feedback of patients and their families on the application of hospital robots is as follows: most of them think that robots perform well in guidance, can guide the route quickly and accurately, save time and reduce anxiety; Medicine delivery robots ensure timely delivery of medicines for peace of mind.

FAQ

1. Why SLAMTEC? SLAMTEC has extensive experience in marketing, production and technology integration. Its business serves more than 2,000 enterprises and 100,000 individual users in 20 countries and regions in Asia, Europe and the Americas.

SLAMTEC ensures R & D, supply chain, pre-sale and post-sale integrity. Its technology products have matured and are applied in the service robot projects of Microsoft, Shell, UBTECH, iFlytek, SoftBank and other companies.

2. Do you have your own factory?

Yes, Slamtec has its own factory.

3. How to place an order?

Please provide us with more details such as: application, measurement range, output, accuracy, thread type, electrical connector and other relevant parameters.

4. What is the lead time for mass production?

It depends on the number of orders. Please chat with us for more details.

5. What are the terms of payment?

Wire transfers, bank account transfers.

6. Warranty

Quality assurance: 12 months.

7. After-sales service?

After receiving our products, if you have any questions or need any help, we can provide you with after-sales service via email, skype, phone and WhatsApp.