Product Description

High precision CNC aluminum parts with multi-functional anodize treatment, specially designed to meet industrial needs with premium customized services, are engineered to provide superior performance and durability in a wide range of demanding applications. Our anodizing process not only enhances the material's surface hardness and wear resistance but also offers excellent corrosion protection, making it ideal for parts exposed to harsh environmental conditions.

Product parameters

| Type | CNC Turning Parts |

| Material | Aluminum 5052, 6061, 6063, 7075, AW5083, AW5754 |

| Surface treatment | Anodize, Nickel Plating, Chrome Plating, Gold Plating, Powder Coating, Painting, Sandcasting, Polished, Mirror Polishing, Brushed, Logo printing |

| Feature | Custom service |

| Sample | Samples Offered |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Die casting

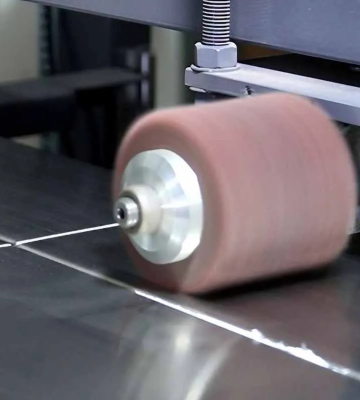

Polishing

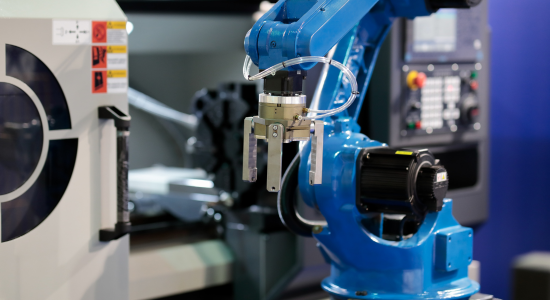

CNC machining

Material

Aluminum Alloy

Stainless Steel

Quality Control

Quality control for high-precision aluminum turned parts is a comprehensive process that ensures every component meets the highest standards of accuracy, performance, and durability. Throughout the manufacturing process, each part is carefully monitored using advanced measurement technologies such as coordinate measuring machines (CMM) and laser scanners to ensure dimensional accuracy and consistency.

Processing capability

The processing capability of high-precision aluminum turned parts involves advanced CNC turning technology, allowing for the production of intricate and complex components with exceptional accuracy and tight tolerances. Using multi-axis CNC lathes, we can perform precise turning, drilling, threading, and grooving operations, enabling the creation of parts with intricate geometries and detailed features. Our capabilities extend to handling a wide range of aluminum alloys, ensuring that each material is selected based on the specific mechanical properties required for the application.

Additional processes

Additional processes for high-precision aluminum turned parts are implemented to enhance their functionality, durability, and aesthetic quality. These processes include surface treatments such as anodizing, which improves corrosion resistance, wear resistance, and surface hardness, providing the parts with a longer lifespan and better performance in harsh environments. For parts requiring specific finishes, processes like polishing, bead blasting, or coating can be applied to achieve the desired texture, appearance, and protective qualities.