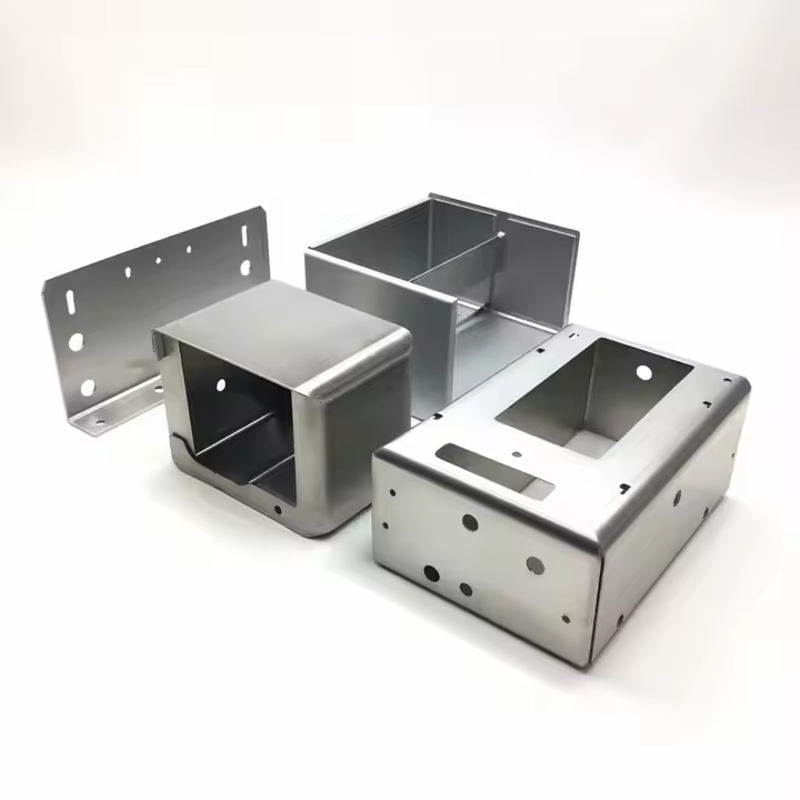

Product Description

Our custom CNC milling and turning services are designed to create precision automotive parts. Using advanced CNC technology, we produce highly accurate components for various car models. We work with materials like aluminum, steel, and plastics to ensure durability and performance. Our services include both complex milling and turning operations for intricate shapes and smooth finishes. Whether for prototypes or production runs, we deliver fast and cost-effective solutions. Trust us to meet your automotive machining needs with exceptional quality and precision.

Product parameters

| List | Details |

|---|---|

| Product name | Custom OEM sheet metal parts |

| Material | Q235B, aluminum, 304 stainless steel |

| Finish | Powder coating/paint/zinced |

| Color | black,grey or Customized |

| Usage | Engineering machinery equipment, other mechanical equipment |

| Surface treatment | Electrostatic spraying, boiling black, galvanizing, oxidizing etc. |

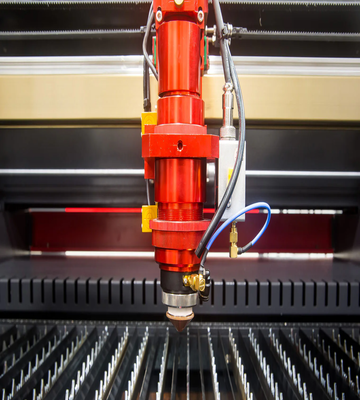

| Process | Metal cutting,bending,welding etc. |

| Drawing | Engineering Drawings |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

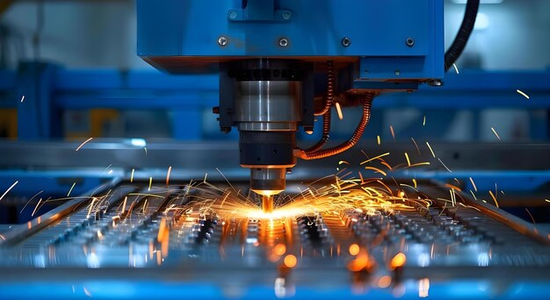

Laser Cutting

Milling & Drilling

Turning

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

Our quality control for custom CNC milling and turning car parts ensures strict precision and reliability. Each component is meticulously inspected for dimensional accuracy and surface finish. We use advanced measurement tools to confirm tolerances and functionality. All parts undergo a comprehensive testing process to meet automotive industry standards. We ensure that every part performs optimally under real-world conditions. Our rigorous QC process guarantees consistent, high-quality results for every project.

Processing capability

Our custom CNC milling and turning services offer precise capabilities for automotive parts manufacturing. We work with a variety of materials including aluminum, steel, titanium, and plastics to meet different performance requirements. Our advanced CNC machines handle complex geometries with high accuracy, ensuring tight tolerances of ±0.01 mm. We provide both 3-axis and multi-axis machining for intricate designs and detailed features. Our process supports turning, milling, drilling, and tapping to create fully functional automotive components. We specialize in creating prototypes as well as high-volume production runs. With fast turnaround times and efficient workflows, we can scale production to meet your needs

Additional processes

Our machines are capable of handling both large and small parts, from engine components to interior pieces. We ensure smooth, precise finishes for all parts with minimal post-processing. We can accommodate a wide range of automotive applications, including performance, aesthetic, and functional parts. Our team works closely with clients to optimize designs for manufacturability and cost-effectiveness. Whether it's for R&D or mass production, our CNC services deliver top-quality results.