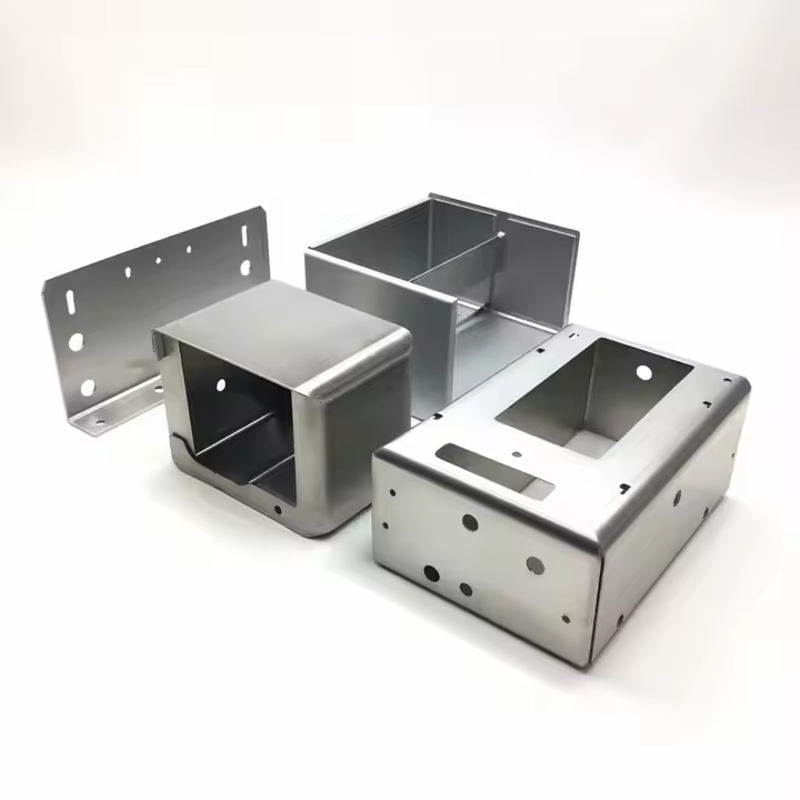

Product Description

Milling Turning Copper involves precise machining of copper components using advanced milling and turning techniques. These processes ensure high accuracy and smooth finishes for complex designs. Copper's excellent conductivity and corrosion resistance make it ideal for electrical and industrial applications. Our skilled technicians maintain tight tolerances to meet custom specifications. We offer various surface treatments, including polishing and coating, to enhance performance. Trusted by industries for its reliability, precision, and quality craftsmanship.

Product parameters

| List | Details |

|---|---|

| Product name | CNC Machine Parts |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Materials Avaliable | Aluminum.etc |

| Process | Cnc Machining+deburrs |

| Surface treatment | Sandblasting |

| Service | Customized OEM CNC Machining |

| Application | Industrial Equipment |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Turning

Milling & Drilling

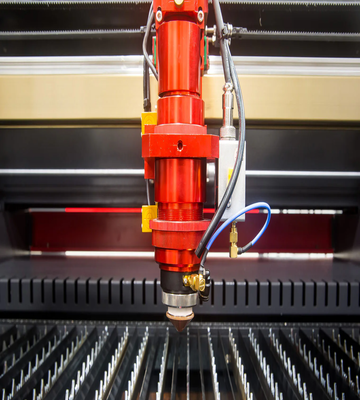

Laser Cutting

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

The QC process for Milling Turning Copper ensures precise dimensional accuracy and surface finish. Each part undergoes detailed inspections, including measurement checks and visual assessments. Advanced testing methods, such as conductivity and corrosion resistance tests, are performed. Any defects or deviations from specifications are identified and corrected promptly. Surface treatments are thoroughly checked for consistency and quality. Only copper parts that pass stringent quality control are approved for shipment.

Processing capability

The processing capability of Milling Turning Copper includes precise CNC milling and turning operations for high-quality copper components. Our advanced machinery ensures tight tolerances and accurate dimensions, ideal for complex and custom designs. We offer a variety of copper grades suitable for electrical, industrial, and mechanical applications. The facility supports high-volume production as well as small-batch runs for prototypes.

Additional processes

Our technicians use precise tools to achieve smooth finishes and detailed features. We provide additional processes like drilling, tapping, and thread cutting to meet specific requirements. Surface treatments such as polishing, coating, and anodizing enhance copper’s durability and appearance. Heat treatment processes can be applied to improve material strength. We ensure the highest standards of material integrity and functionality. The production process is highly flexible, accommodating both simple and intricate designs. Rigorous quality control checks are conducted to ensure superior product consistency. Our services cater to industries like electronics, automotive, and machinery.