Product Description

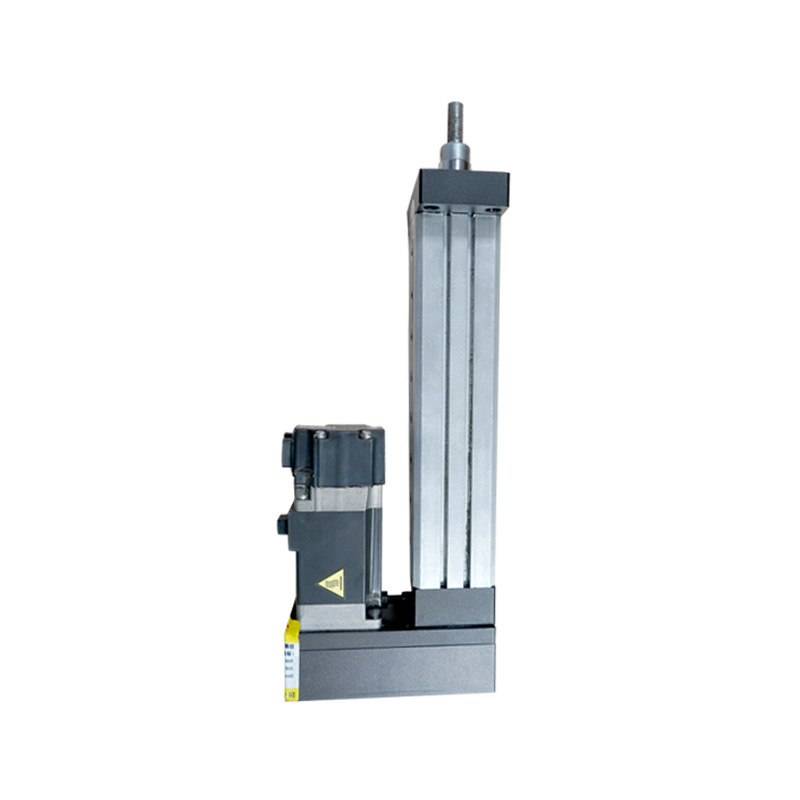

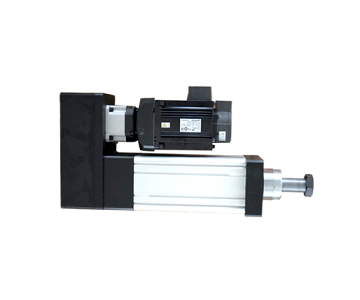

The large thrust and long stroke servo electric cylinder can produce a large thrust, ranging from thousands of Newtons to tens of tons, which can meet the driving needs of various heavy loads, such as the motion control of large equipment in aerospace, automobile manufacturing, construction machinery and other fields. With a long stroke, it can achieve a large distance of linear motion, and the stroke length is generally between several hundred millimeters and several meters, which can meet some application scenarios that require a wide range of motion. With the closed-loop servo control technology, the control accuracy can reach 0.01mm or even higher, which can achieve accurate speed control, position control and thrust control, and can meet the requirements of various high-precision motion control, such as precision machining equipment, medical equipment and other fields.

Product parameters

| Model number | TYSC135 | |||||||

|---|---|---|---|---|---|---|---|---|

| Motor mounting mode | direct-connected | reentrant | ||||||

| Screw diameter (mm) | 50 | |||||||

| Screw lead (mm) | 5 | 10 | 20 | 50 | 5 | 10 | 20 | 50 |

| Effective travel (mm) | 0-2000 | |||||||

| Rated output (KN) | 20 | 50 | 50 | 20 | 20 | 50 | 50 | 20 |

| Maximum output (KN) | 22 | 55 | 55 | 25 | 22 | 55 | 55 | 25 |

| Reduction ratio | 1:1/1:3/1:4/1:5/1:10/1:20 | |||||||

| Motor Power (W) | 1kw/2kw/3kw/5kw/7.5kw | |||||||

| Rated speed (mvs) | 250 | 500 | 1000 | 1600 | 250 | 500 | 1000 | 1600 |

| Internal anti-turning mechanism | Yes/no | |||||||

| Limit switch | Yes/no | |||||||

| Repeated positioning accuracy (mm) | ±0.02 | |||||||

| Electric cylinder installation mode | Bottom thread hole | |||||||

| Bottom plate | ||||||||

| Front flange | ||||||||

| Tail flange | ||||||||

| Tail pin | ||||||||

| Tail pin hole | ||||||||

| custom | ||||||||

| Load connection mode | Male thread | |||||||

| Internal thread | ||||||||

| Rod end joint bearing | ||||||||

| Double bolt hole at rod end | ||||||||

| custom | ||||||||

| Class of protection | Ip65 | |||||||

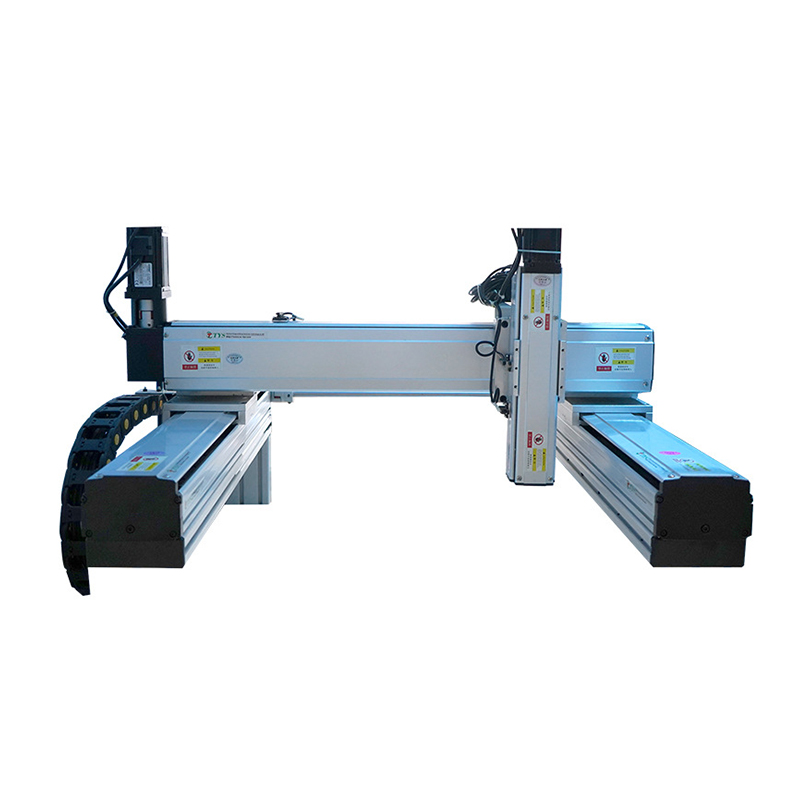

Product Display

The characteristics of servo electric cylinder: energy saving and environmental protection, low noise, high speed, high precision, fast response, long life, can work in the harsh environment without trouble for a long time. Therefore, it can be used in the field of mechanical automation, automotive industry, chemical industry, military manufacturing, large-scale special scene simulation and other fields and industries.

The electric cylinder mainly saves costs from six aspects: improving energy efficiency, reducing heat loss, improving production speed, improving material utilization, extending uptime, and simplifying maintenance processes.

Large thrust output: As can be seen from the name, large thrust is its significant advantage. Through specially designed screws, nuts and powerful drive motors, thousands or even tens of thousands of cows of thrust can be generated. In the large stamping equipment of automobile manufacturing, the large thrust servo electric cylinder can provide stable and strong pressure to press the steel plate into various auto parts, ensuring production efficiency and product quality.

Adapt to heavy load conditions: with high-strength structural design and high-quality material selection, it can stably withstand huge loads for a long time, and is not easy to appear structural deformation, parts wear and other problems. In material handling systems in the mining industry, electric cylinders need to frequently push or pull conveyor belts weighing several tons to achieve efficient material transportation.

Application Cases

Suzhou Tongyousheng Electronic Technology Co., LTD., specializing in the production of servo electric cylinder, linear slide module, servo press, multi-dimensional free movement platform robot, robot series products. And provide Mitsubishi, Panasonic industrial control products, PLC, servo motor, inverter, touch screen, guide rail, screw, reducer series products.

Cooperative partner

Service

- Pre-sales -- Help reasonable selection: project evaluation engineers docking, in-depth communication to understand the use of conditions, to confirm the appropriate selection and specifications, to give customers reasonable suggestions, effectively avoid problems in production

- Sales -- Ensure production delivery: dedicated engineers and business specialists docking, project managers to process control, active communication and interaction, timely detection of problems and timeliness communication, for the production delivery escort

- After-sales -- Timely response processing: after-sales engineering personnel docking, the same day response; And timely to the scene to confirm, discuss, solve and deal with problems, to meet customer production needs, to avoid downtime and production