Product Description

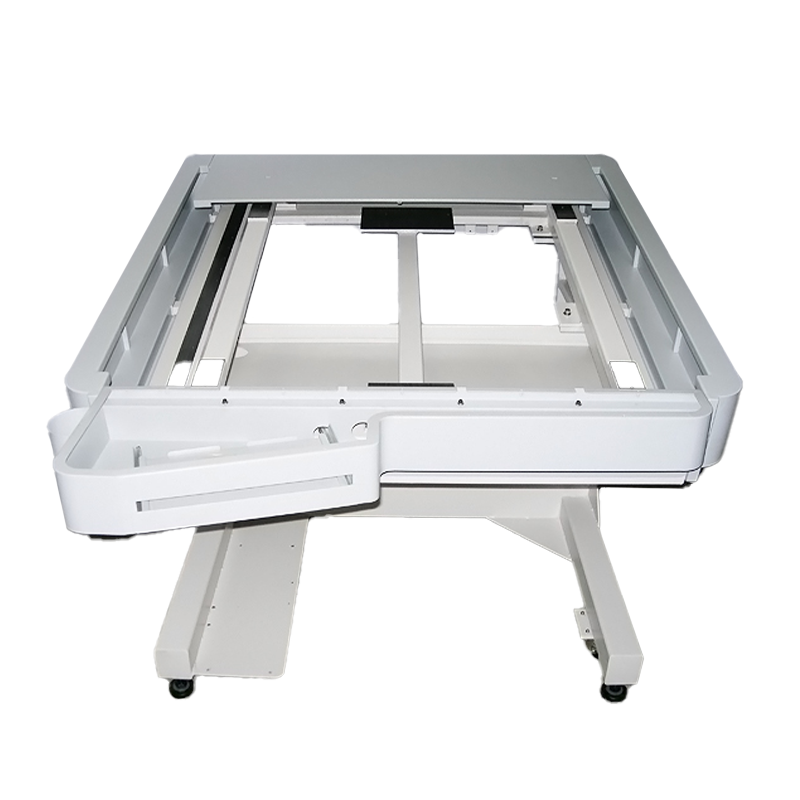

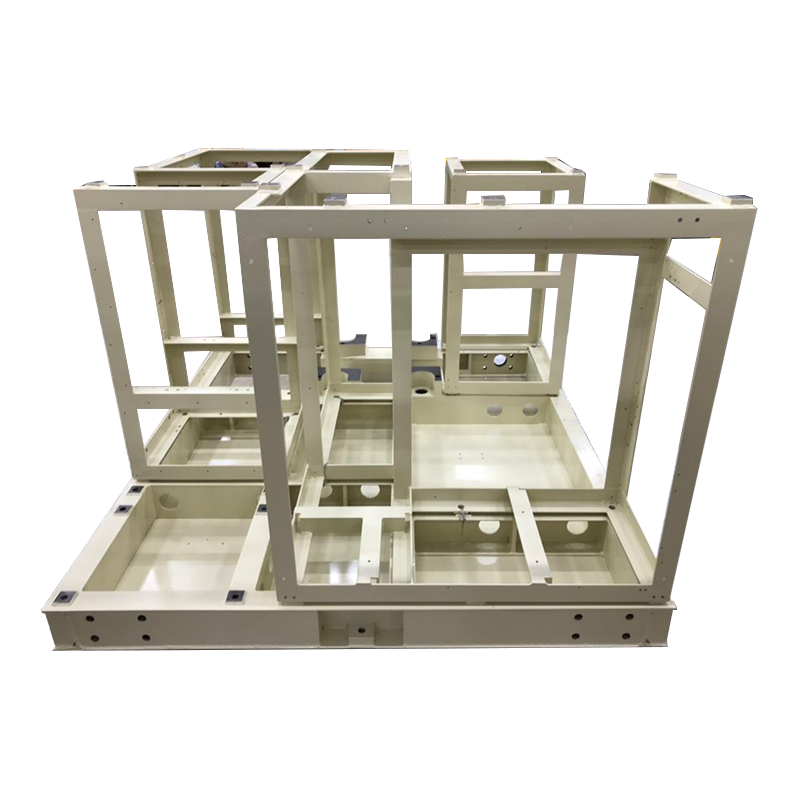

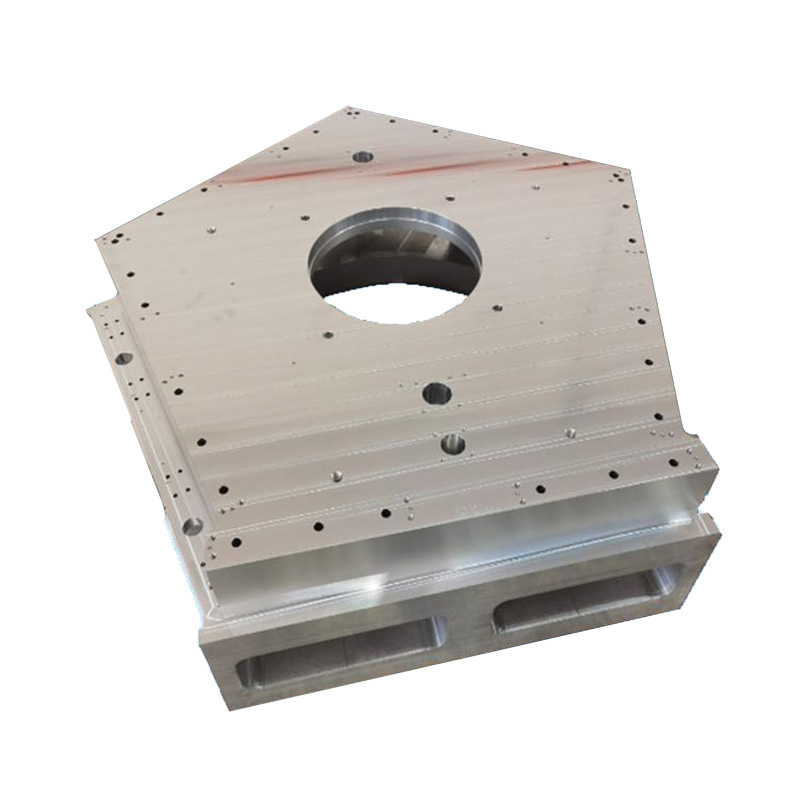

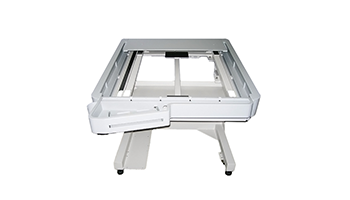

Our non-standard precision sheet metal welding parts are carefully crafted by a professional team. Using advanced sheet metal processing technology, cutting is accurate and the size meets the standard. The welding technology is superb, the welds are uniform and firm, and the strength and stability are improved. From material selection to finished product inspection, each link is strictly controlled and follows high standards. It is suitable for industrial equipment, automation machinery, electronic equipment and other fields, providing reliable guarantee for the project.

Product parameters

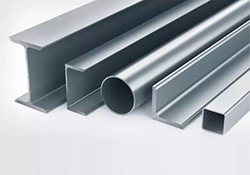

| Material | Steel , Iron ,Stainless steel, Aluminum, Brass, Copper etc. |

| Process | Welding, Stamping, Laser cutting, Bending, CNC, etc. |

| Surface treatment | Galvanizing, Polishing, Anodizing, Powder coating, etc. |

| Size | Customized Size |

| Certificate | ISO 9001:2015 |

Custom Process

1.Requirements communication

2.Scheme design

3.Quotation accounting

4.Contract signing

5.Raw material procurement

6.Processing and Manufacturing

7.Quality Inspection

8.Delivery acceptance

Material

Copper Alloy

Aluminum Alloy

Aluminum

Stainless steel

Quality Control

In the field of precision machining and non-standard precision sheet metal welding, quality is our uncompromising commitment. From the strict selection of raw materials at the beginning, to the precise control of each process during processing, to multiple rounds of fine testing after welding, we have built a strict and complete quality control system. With a professional team and advanced technology, we strictly monitor the entire production process to ensure that each product meets high-precision standards and win the trust and praise of customers with excellent quality.

Processing capability

ORBITAL WELDING x 1

Welding PIPE Diameter Range

: 6 to 38.0mm

: 12 to 76.0 mm

Weldable Material

: Carbon Steel, / SST

:TitaniumAlloy / etc

Welding Shielding Gas : Argon

Wall Thickness : up to 3.0 mm

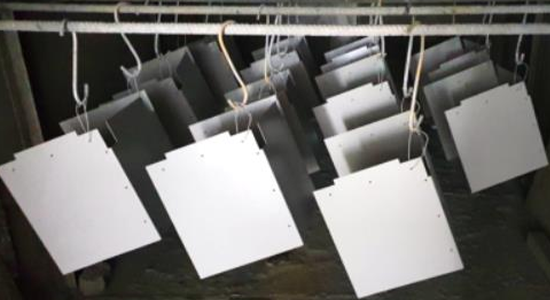

Additional processes

Internal powder coating process

We use an in-house powder spraying process to evenly adhere the powder to the surface of the workpiece using the principle of electrostatic adsorption. This process is environmentally friendly and efficient, with strong coating adhesion and good corrosion resistance. After high-temperature curing, the formed coating is flat and smooth, with long-lasting and bright colors, providing all-round protection and aesthetic protection for the product.