Product Description

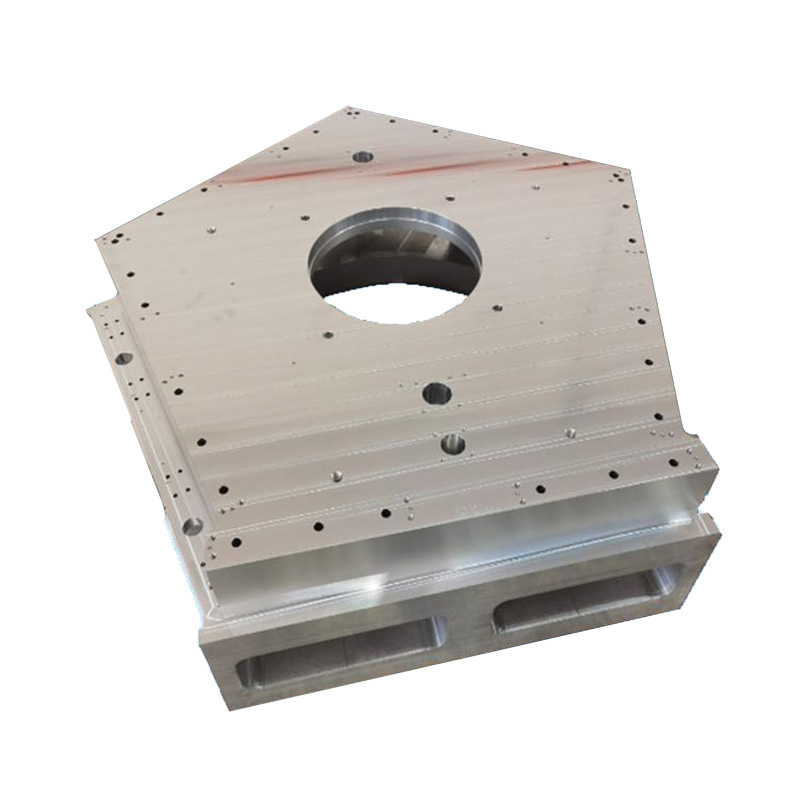

The precision customized sheet metal welded parts produced by our company are ideal for industrial manufacturing. They are produced in strict accordance with high-precision standards to ensure that every detail is accurate. They can be customized according to the diverse needs of customers, whether it is a complex structural design or a special size specification, they can be perfectly realized. The use of advanced welding technology ensures that the welding parts are firm and reliable, and the overall performance is excellent. They are widely used in many fields such as aerospace, automobile manufacturing, and electronic equipment.

Product parameters

| Service | Professional custom sheet metal fabrication services. |

| Color | Customized Color |

| Size | Customer Request |

| Logo | Accept Customized Logo |

| Thickness | Customized Thickness |

Custom Process

1.Requirements communication

2.Scheme design

3.Quotation accounting

4.Contract signing

5.Raw material procurement

6.Processing and Manufacturing

7.Quality Inspection

8.Delivery acceptance

Process Type

Laser cutting

With the help of the high temperature generated by the focused high-energy laser beam, the material is instantly melted or vaporized, and the sheet is cut with extremely high precision, with narrow and smooth cuts.

CNC milling

The milling machine is controlled by a computer digital program, which can precisely control the multi-axis linkage of the tool and can process parts of various complex shapes.

Surface grinding

Use a high-speed rotating grinding wheel to perform micro-cutting on the surface of the workpiece, greatly improving the surface flatness and finish.

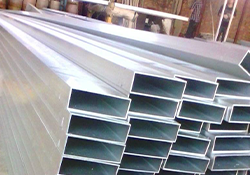

Material

Stainless steel

Aluminum

Aluminum Alloy

Copper Alloy

Quality Control

Quality control is crucial in the production of precision customized sheet metal welded parts. Strict screening and testing are carried out from the source of raw materials to ensure that the materials meet the standards. On the production line, technicians use their superb skills and advanced equipment technology to monitor and accurately operate each process in real time. After welding is completed, high-precision instruments are used to fully test the finished products according to strict standards, without missing any minor defects. Products that have passed rigorous inspections are finally delivered to ensure excellent quality and reliable performance.

Processing capability

Lathe/CNC TURN Machine:

"TAKISAWA" CNC LATHE MACHINE(NEX 108 ) 2 UNITS

"TAKISAWA" CNC LATHE MACHINE(TC 100) 1 UNIT

"TAKISAWA" TURN & MILL MACHINE(NEX 108 Y) 1 UNIT

"CHARLES" Precision Lathe 1

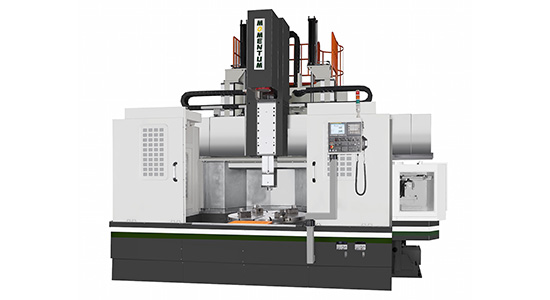

"MOMENTUM" VERTICAL TURNING LATHE MACHINE(MVL-12) 1 UNIT