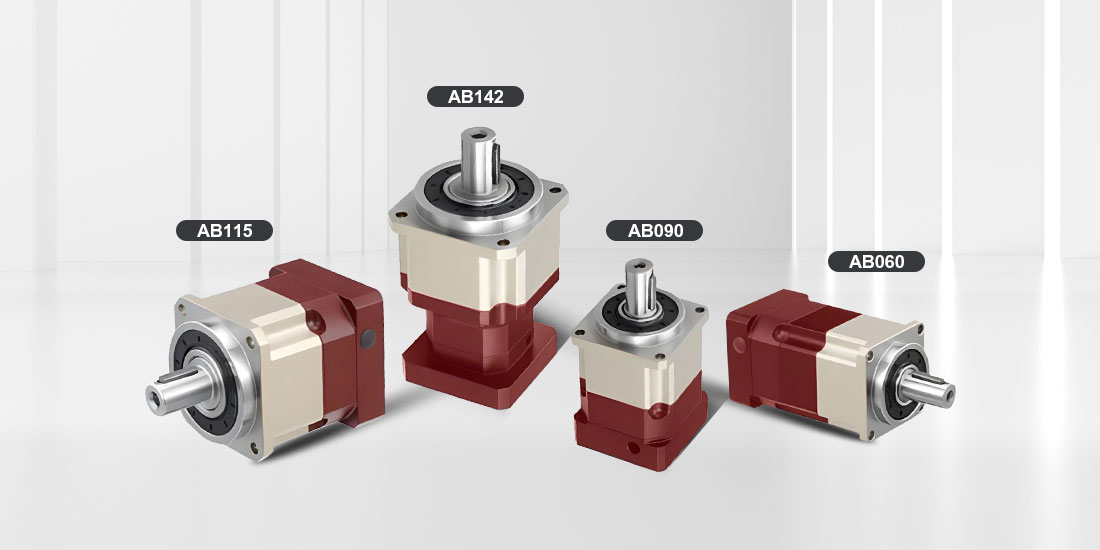

Product Description

AB series precision planetary gear reducer, precise transmission, stable and reliable

Precision planetary reducer has the characteristics of small structure size,large output torque,wide speed ratio range,high efficiency,safe and reliable performance,etc.This machine is mainly used for tower crane slewing mechanism,and can also be used as supporting components for overweight,mining,transportation,construction and other industries Can be directty installed on AC and DC servo motors,and is widely used in medium precision packaging.automatic generation industry,industria robots and automatic mechanical and electrical products industry.

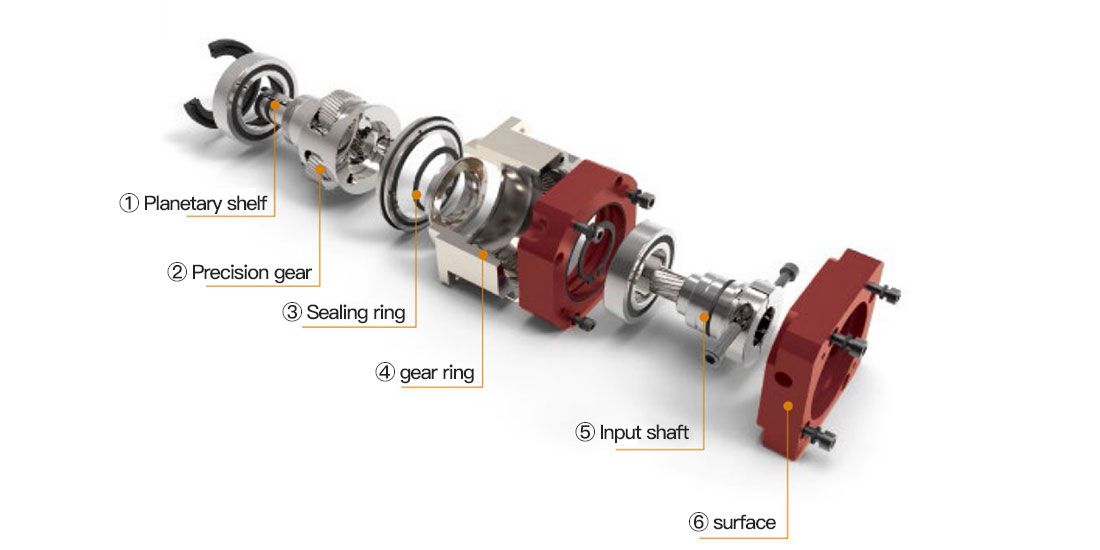

Functional Features

Planetary frame: adopts the integrated double support structure, the front and rear bearings are distributed in the box with a long span to ensure high torsional rigidity and accuracy.

Gear: Gear material is made of high quality alloy steel, after carbon-nitriding treatment, wear resistance and impact toughness is the best.

Seal ring: ANSYS technology performs finite element analysis of gear strength to reduce dimensional impact and noise and increase life.

Gear ring: Integrated design with output housing using high-quality steel, with higher strength and accuracy.

Input shaft: Integrated with the tightening device design double bolts symmetrical distribution, effectively prevent the motor shaft from slipping.

Surface: Advanced surface treatment wear resistance, scratch resistance, corrosion resistance

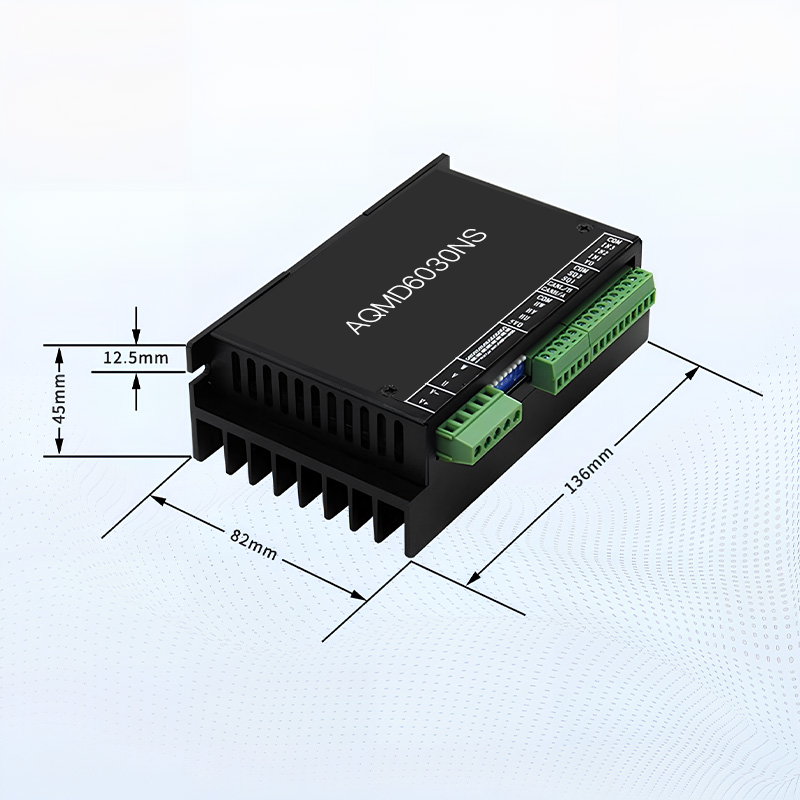

Dimensional drawing

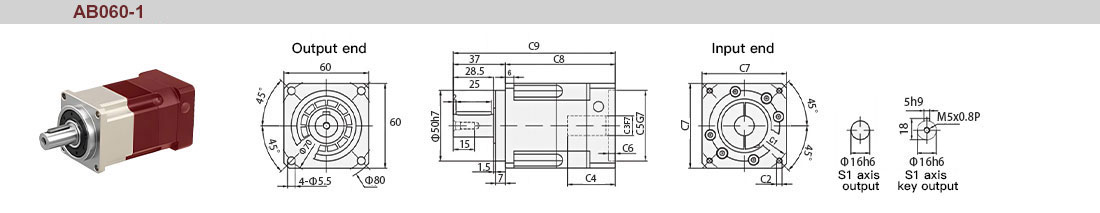

■ AB060planetary gear reducer

Input size table | Decelerometer | |||||||||||

Dimension | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | Dimension | Reduction ratio | |

AB060-1 | φ70 | 4-M4×10,4-M5×12 | φ11 φ14 | 34 | φ50 | 5 | 60 | 115 | 115 | AB060-1 | 3/4/5/6/7/8/10 | |

φ90 | 4-M5×12,4-M6×13 | φ19 | 34 | φ50 | 5 | 80 | 125 | 125 | ||||

*C1-C7 is the size of the metric standard motor connection plate, which can be customized according to customer requirements. | ||||||||||||

Input size table | Decelerometer | |||||||||||

尺寸 | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | Dimension | Reduction ratio | |

AB060-2 | φ70 | 4-M4×10,4-M5×12 | φ11 φ14 | 34 | φ50 | 5 | 60 | 105 | 142 | AB060-2 | 12/15/20/25/30/35/40/50 60/70//80/100 | |

*C1-C7 is the size of the metric standard motor connection plate, which can be customized according to customer requirements. | ||||||||||||

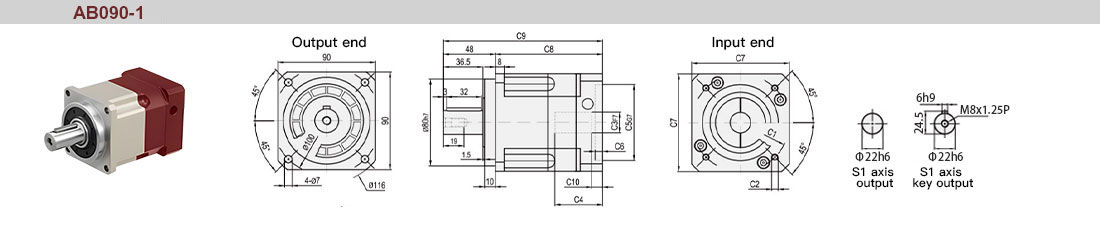

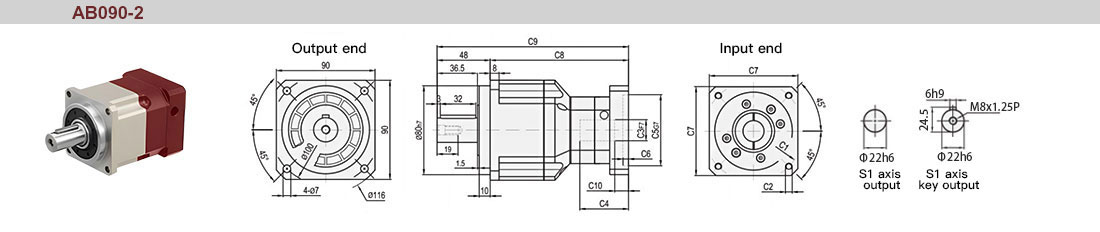

■ AB090planetary gear reducer

Input size table | Decelerometer | ||||||||||||

Dimension | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | Dimension | Reduction ratio | |

AB090-1 | φ90 | 4-M5×12,4-M6×12 | φ19 | 44 | φ70 | 7 | 90 | 99 | 147 | 8 | AB090-1 | 3/4/5/6/7/8/10 | |

φ100 | 4-M6×12 | φ16 | 44 | φ80 | 7 | 90 | 99 | 147 | 7 | ||||

φ115 | 4-M8×20 | φ19 φ22 | 50 | φ95 | 7 | 100 | 105 | 153 | 13 | ||||

φ115 | 4-M8×25 | φ19 φ22 | 60 | φ95 | 8 | 100 | 115 | 163 | 23 | ||||

φ145 | 4-M8×20 | φ19 φ22 φ24 | 60 | φ110 | 8 | 130 | 115 | 163 | 23 | ||||

*C1-C7 is the size of the metric standard motor connection plate, which can be customized according to customer requirements. | |||||||||||||

Input size table | Decelerometer | ||||||||||||

Dimension | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | Dimension | Reduction ratio | |

AB090-2 | φ70 | 4-M4×10,4-M5×12 | φ11 φ14 | 34 | φ50 | 5 | 60 | 15 | 163 | 5.5 | AB090-2 | 12/15/20/25/30/35/ 40/50/60/70//80/100 | |

φ90 | 4-M5×12,4-M6×12 | φ19 | 44 | φ70 | 5 | 80 | 125 | 173 | 16.5 | ||||

φ100 | 4-M6×12 | φ16 | 38.5 | φ80 | 5 | 86 | 19.5 | 67.5 | 10 | ||||

*C1-C7 is the size of the metric standard motor connection plate, which can be customized according to customer requirements. | |||||||||||||

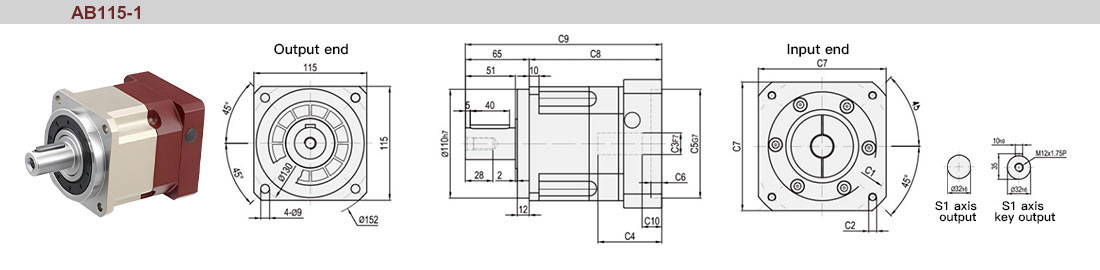

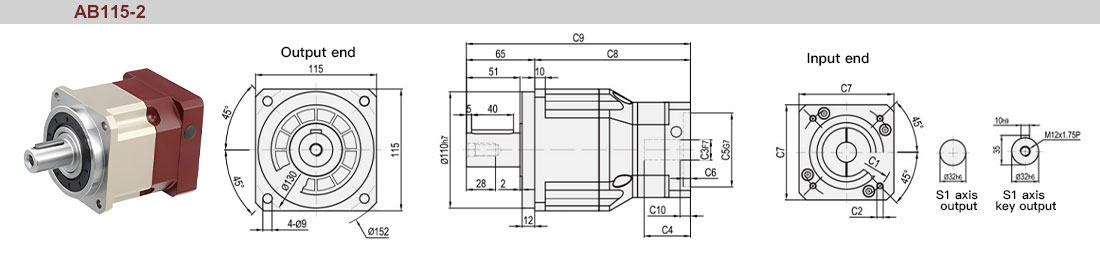

■ AB115planetary gear reducer

Input size table | Decelerometer | ||||||||||||

Dimension | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | Dimension | Reduction ratio | |

AB115-1 | φ145 | 4-M8×25 | φ19 φ22 φ24 | 65 | φ110 | 11 | 130 | 135 | 200 | 20 | AB115-1 | 3/4/5/6/7/8/10 | |

φ200 | 4-M12×28 | φ35 | 80.5 | φ114.3 | 6 | 180 | 180 | 215.5 | 36.5 | ||||

*C1-C7 is the size of the metric standard motor connection plate, which can be customized according to customer requirements. | |||||||||||||

Input size table | Decelerometer | ||||||||||||

Dimension | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | Dimension | Reduction ratio | |

AB115-2 | φ90 | 4-M5×12,4-M6×12 | φ19 | 44 | φ70 | 7 | 90 | 48 | 213 | 8 | AB115-2 | 12/15/20/25/30/35/ 40/50/60/70//80/100 | |

φ100 | 4-M6×12 | φ16 | 44 | φ80 | 7 | 90 | 148 | 213 | 7 | ||||

φ115 | 4-M8×20 | φ19φ22 | 50 | φ95 | 7 | 100 | 154 | 219 | 13 | ||||

φ115 | 4-M8×25 | φ19 φ22 | 60 | φ95 | 8 | 100 | 164 | 229 | 23 | ||||

φ145 | 4-M8×20 | φ19 φ22 φ24 | 60 | φ110 | 8 | 130 | 164 | 229 | 23 | ||||

*C1-C7 is the size of the metric standard motor connection plate, which can be customized according to customer requirements. | |||||||||||||

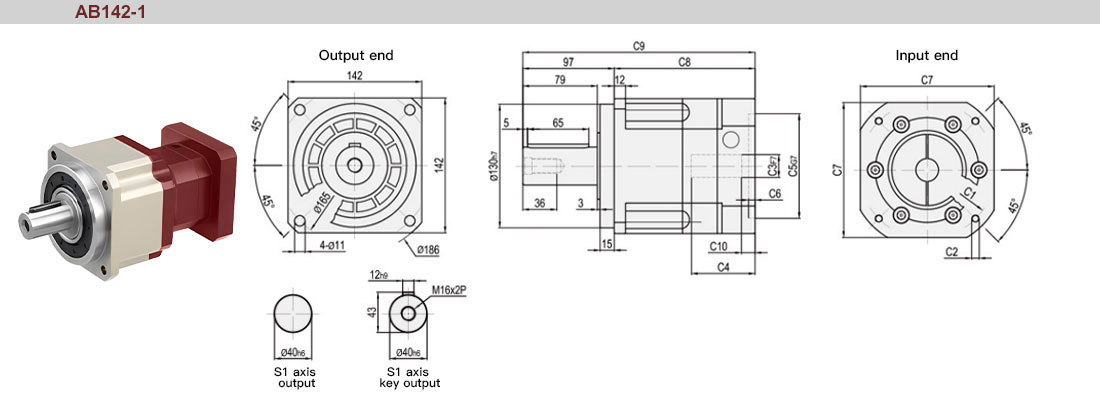

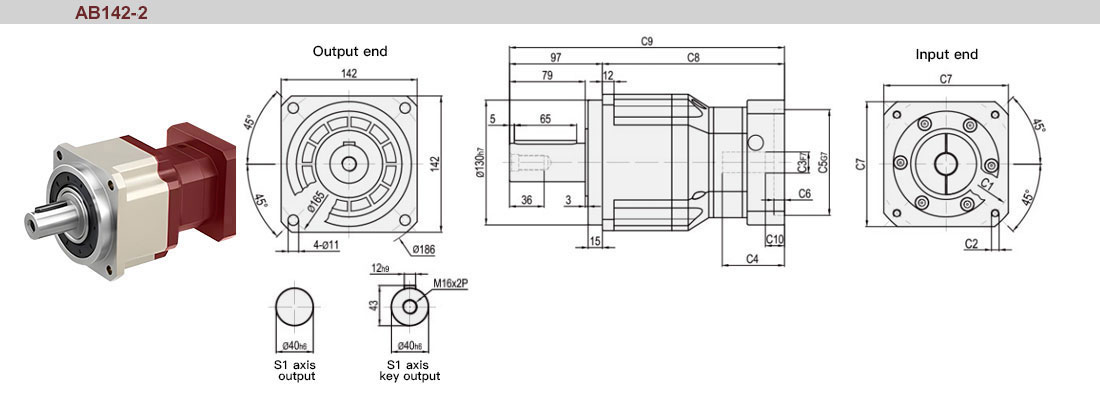

■ AB142planetary gear reducer

Input size table | Decelerometer | ||||||||||||

Dimension | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | Dimension | Reduction ratio | |

AB142-1 | φ145 | 4-M8×25 | φ22 φ24 | 67.5 | φ110 | 7 | 142 | 149.5 | 246.5 | 14.5 | AB142-1 | 3/4/5/6/7/8/10 | |

φ200 | 4-M12×23 | φ35 | 83 | φ114.3 | 8 | 180 | 165 | 262 | 30 | ||||

*C1-C7 is the size of the metric standard motor connection plate, which can be customized according to customer requirements. | |||||||||||||

Input size table | Decelerometer | ||||||||||||

Dimension | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | Dimension | Reduction ratio | |

AB142-2 | φ145 | 4-M8×25 | φ19 φ22 φ24 | 65 | φ110 | 11 | 130 | 149.5 | 287 | 20 | AB142-2 | 12/15/20/25/30/35/ 40/50/60/70//80/100 | |

φ200 | 4-M12×28 | φ35 | 80.5 | φ114.3 | 6 | 180 | 205.5 | 302.5 | 36.5 | ||||

*C1-C7 is the size of the metric standard motor connection plate, which can be customized according to customer requirements. | |||||||||||||

Product parameters

■ Techical Performance | |||||||

specification | unit | series | Reduction ratio | AB060 | AB090 | AB115 | AB142 |

Rated output torque T2N | Nm | 1 | 3 | 55 | 130 | 208 | 342 |

4 | 50 | 140 | 290 | 542 | |||

5 | 60 | 160 | 330 | 650 | |||

6 | 55 | 150 | 310 | 600 | |||

7 | 35 | 140 | 300 | 550 | |||

8 | 3 | 120 | 260 | 500 | |||

10 | 23 | 48 | 140 | 370 | |||

2 | 12 | 55 | 130 | 208 | 342 | ||

15 | 55 | 130 | 208 | 342 | |||

20 | 50 | 140 | 290 | 542 | |||

25 | 60 | 160 | 330 | 650 | |||

30 | 60 | 160 | 330 | 650 | |||

35 | 60 | 160 | 330 | 650 | |||

40 | 60 | 160 | 330 | 650 | |||

50 | 60 | 160 | 330 | 650 | |||

60 | 55 | 150 | 310 | 600 | |||

70 | 35 | 140 | 300 | 550 | |||

80 | 35 | 120 | 260 | 500 | |||

100 | 23 | 48 | 140 | 370 | |||

Maximum output torque T | Nm | 1.2 | 3-100 | 3 times rated output torque | |||

Rated output speed N | rpm | 1.2 | 3-100 | 5000 | 4000 | 4000 | 3000 |

Maximum output speed N | rpm | 1.2 | 3-100 | 10000 | 8000 | 8000 | 6000 |

Ultra precision backlash PO | arcmin | 1 | 43534 | — | ≤1 | ≤1 | ≤1 |

2 | 12-100 | 二 | ≤3 | ≤3 | ≤3 | ||

Precision backlash P1 | arcmin | 1 | 45726 | ≤3 | ≤3 | ≤3 | ≤3 |

2 | 12-100 | ≤5 | ≤5 | ≤5 | ≤5 | ||

Standard back clearance | arcmin | 1 | 45726 | ≤5 | ≤5 | ≤5 | ≤5 |

2 | 12-100 | ≤7 | ≤7 | ≤7 | ≤7 | ||

Torsional rigidity | Nm/arcmin | 1.2 | 3-100 | 7 | 14 | 25 | 50 |

Allowable radial force F2rb² | N | 1.2 | 3-100 | 1530 | 3250 | 6700 | 9400 |

Allowable axial force F2r1b² | N | 1.2 | 3-100 | 630 | 1300 | 3000 | 4000 |

Allowable axial force F2r2b² | N | 1.2 | 3-100 | 765 | 1625 | 3350 | 4700 |

Service life | hr | 1.2 | 3-100 | 20000* | |||

efficiency | % | 1 | 45726 | ≥97% | |||

2 | 12-100 | ≥94% | |||||

weight | kg | 1 | 45726 | 1.3 | 3.7 | 7.8 | 14.5 |

2 | 12-100 | 1.9 | 4.1 | 9 | 17.5 | ||

Service temperature | ℃ | 1.2 | 12-100 | -10℃~+90℃ | |||

oiling | 1.2 | 3-100 | Japan imported lubricating oil | ||||

Class of protection | 1.2 | 3-100 | IP65 | ||||

Mounting direction | 1.2 | 3-100 | Arbitrary direction | ||||

Voice value | Db | 1.2 | 3-100 | ≤58 | ≤60 | ≤63 | ≤65 |

■ Moment of inertia of reducer | |||||||

specification | unit | series | Reduction ratio | AB060 | AB090 | AB115 | AB142 |

The moment of inertia J | kg.cm² | 1 | 3 | 0.16 | 0.61 | 3.25 | 9.21 |

4 | 0.14 | 0.48 | 2.74 | 7.54 | |||

5 | 0.13 | 0.47 | 2.71 | 7.42 | |||

6 | 0.13 | 0.45 | 2.65 | 7.25 | |||

7 | 0.13 | 0.45 | 2.62 | 7.14 | |||

8 | 0.13 | 0.44 | 2.58 | 7.07 | |||

10 | 0.13 | 0.44 | 2.57 | 7.03 | |||

2 | 12 | 0.03 | 0.03 | 0.47 | 2.71 | ||

15 | 0.03 | 0.03 | 0.47 | 2.71 | |||

20 | 0.03 | 0.03 | 0.47 | 2.71 | |||

25 | 0.03 | 0.03 | 0.47 | 2.71 | |||

30 | 0.03 | 0.03 | 0.47 | 2.71 | |||

35 | 0.03 | 0.03 | 0.47 | 2.71 | |||

40 | 0.03 | 0.03 | 0.47 | 2.71 | |||

50 | 0.03 | 0.03 | 0.44 | 2.57 | |||

60 | 0.03 | 0.03 | 0.44 | 2.57 | |||

70 | 0.03 | 0.03 | 0.44 | 2.57 | |||

80 | 0.03 | 0.03 | 0.44 | 2.57 | |||

100 | 0.03 | 0.03 | 0.44 | 2.57 | |||

1. Deceleration ratio (i=Nin/Nout) Continuous operation reduces the service life by half | |||||||

Application

Productsarewidey usedin vanious industialpoduction ines,conveyng machinery,food machinery medical machiney,prntng machinery textle machinery,ofice equpment,instrumentaton,avetsing industy,recreaional facltes,francial equpment,househotd applances,intelient robots and ofher felds,is the pefered matcning products of automation equipment.

Service

Dedicated service, along the way

Warranty worry-free, extended repair, often return to promote optimization, peace of mind choice, all in control.

Before the purchase of professional consultants rapid response, accurate recommendation products;

Purchase logistics is efficient, specially-assigned to ensure delivery;

After the purchase 7×24 hours customer service answer questions, engineers at any time to save the "machine";

After-sale guarantee

After-sales service: We provide comprehensive after-sales technical support, if you encounter any problems in the process of use, the professional after-sales engineer team will respond quickly, through telephone, mail or remote assistance, to provide you with detailed solutions. We also provide regular return visits to our products to understand how they are used and to collect your feedback in order to continuously optimize our products and services. In addition, in strict accordance with the quality assurance policy, we provide free repair or replacement services for products with quality problems during the warranty period, so that you have no worries.