Product Description

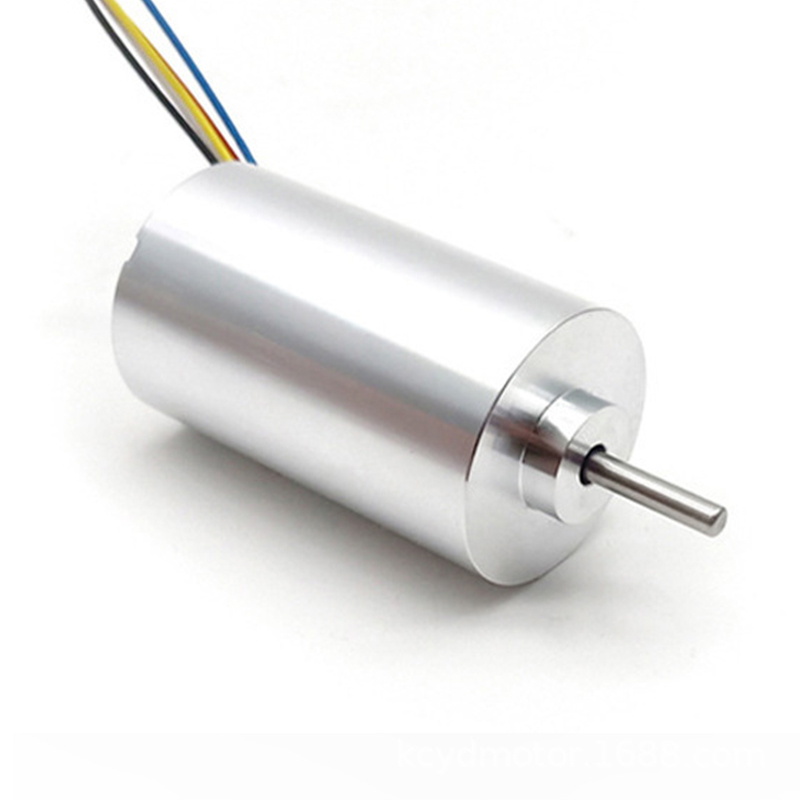

Dc hollow cup brushless motor High power series with outstanding characteristics. In terms of power output, it can provide powerful power to meet the heavy load operation needs, and the output torque is far more than the ordinary model. Outstanding performance in high efficiency and energy saving, advanced winding design and optimization of magnetic circuit, to achieve efficient conversion of electrical energy to mechanical energy, reduce energy consumption. The motor is made of high quality material, strong mechanical structure, can withstand long time high load operation, and strong durability. The response speed is extremely fast, the hollow cup structure with brushless technology, can quickly start and stop, accurate speed regulation. Moreover, its smooth operation, low vibration, low noise, weak electromagnetic interference, to provide stable power support for equipment with severe environmental requirements.

Product parameters

Brushless motor Ball bearing | ||||||||

Model number | 2408 | 2406 | 3609 | 3605 | 4809 | 4805 | ||

Rated voltage | V | 24 | 24 | 36 | 36 | 48 | 48 | |

No-load speed ±12% | rpm | 8488 | 6063 | 9095 | 5093 | 8935 | 4993 | |

No-load current Max150% | mA | 521 | 358 | 375 | 178 | 281 | 125 | |

Recommended limit value for continuous operation | Maximum continuous torque | mN.m | 207.33 | 235.65 | 205.07 | 257.99 | 201.04 | 263.93 |

Rated speed | rpm | 7995 | 5529 | 8626 | 4533 | 8474 | 4425 | |

Maximum continuous current | mA | 8200 | 6600 | 5800 | 4000 | 4200 | 3000 | |

Rated power | W | 173.59 | 136.62 | 185.23 | 122.46 | 178.4 | 122.3 | |

Starting current | mA | 141176 | 75000 | 112500 | 36364 | 81356 | 26374 | |

Locked-rotor moment | mN. m | 3812 | 2835 | 4253 | 2455 | 4174 | 2421 | |

Maximum output power | W | 847.1 | 450 | 1012.5 | 327.3 | 976.3 | 316.5 | |

Maximum efficiency value | % | 88 | 87 | 89 | 86 | 89 | 87 | |

End resistance ±12% | Ω | 0.18 | 0.32 | 0.32 | 0.99 | 0.59 | 1.82 | |

inductance (1KHZ) | mH | 0.19 | 0.068 | 0.064 | N/A | N/A | 0.37 | |

Mechanical time constant | ms | 0.32 | 1.69 | 1.69 | 1.64 | 1.69 | 1.63 | |

Moment of inertia | gcm2 | 74.56 | 74.56 | 74.56 | 74.56 | 74.56 | 74.56 | |

Torque constant | mN.m/A | 27 | 37.8 | 37.8 | 67.5 | 51.3 | 91.8 | |

Speed constant | rpm/V | 354 | 253 | 253 | 141 | 186 | 104 | |

Speed/torque slope | rpm/mN.m | 2.2 | 2.1 | 2.1 | 2.1 | 2.1 | 2.1 | |

Motor weight | g | 480 | 480 | 480 | 480 | 480 | 480 | |

Relevant information | ||||||

Thermal resistance of motor 4.2 K/W | Thermal time constant of motor 1380 S | |||||

Dynamic load: axial 6.0 N | Dynamic load: radial (5mm outside face) 28.0 N | |||||

Maximum installation force (static) 110 N | Maximum driving depth of mounting screw 4.0mm | |||||

Radial clearance (5mm outside face) ≤0.02 mm | Axial clearance 0 (<6.0N ) | |||||

Maximum coil temperature 155ºC | Ambient temperature -30 to 65ºC | |||||

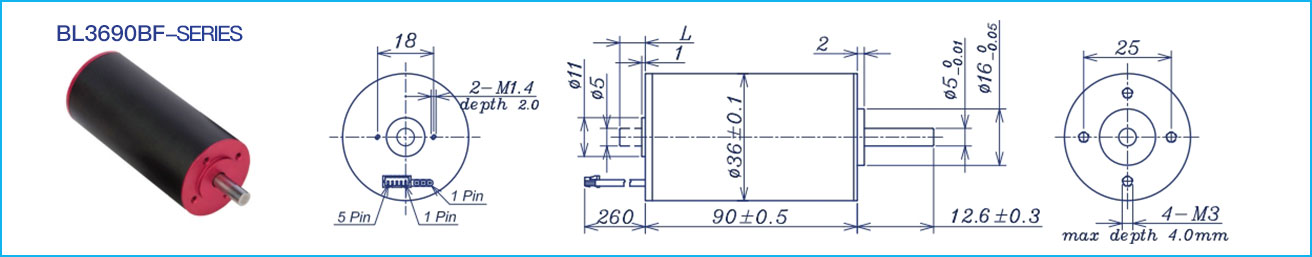

Standard rear axle diameter 5 mm | Standard rear axle Length "L" 0/3.7/5.5 mm | |||||

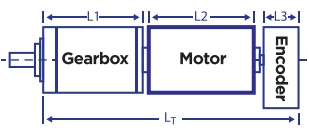

Lead Definition (AWG 20#)) | Total length of gear motor: LT=L1+L2+L3 | BL3690BF Recommended combination options | ||||

Lead 1: yellow motor winding A | L1:36GP | L1:40GP | L2:BL36 | L3:EN22S | L3:EN36T |

|

Lead 2: Red motor winding B | 39.6 | 46.8 | 90 | 10.7 | 12 | |

Lead 3: Blue motor winding C | 48.6 | 58.3 | ||||

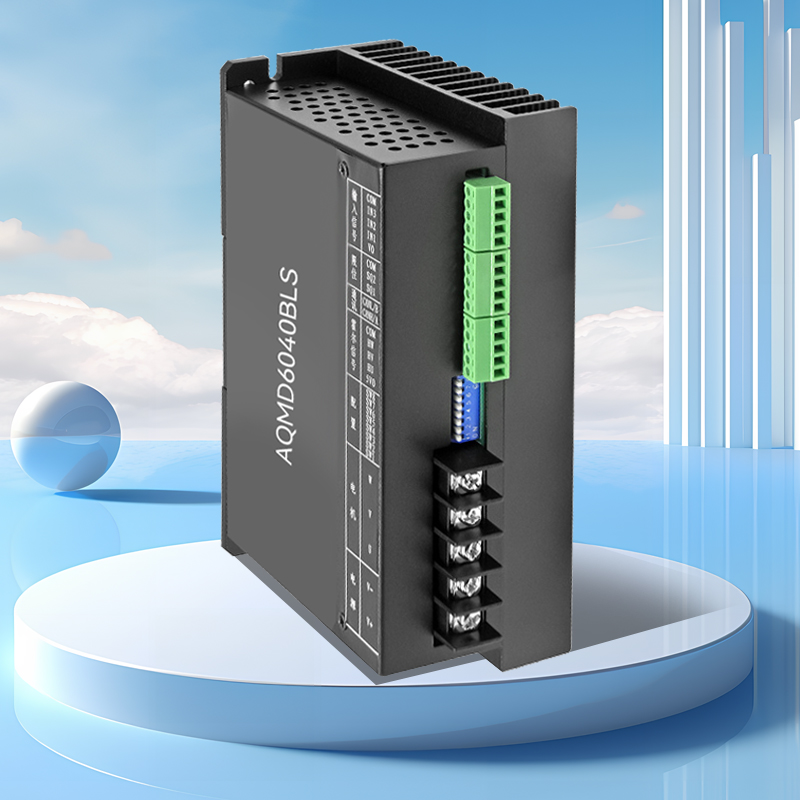

Sensor Pin Definition (AWG 28#) Molex:51021-0500 | 57.6 | 69.8 | ||||

Pin 1: Brown Hall Vcc 3 to 16V | ||||||

Pin 2: Black Hall GND | Note: Customers can choose the corresponding gear box and encoder to match with the motor, more product combinations, please contact our sales staff. | Recommended gear box: 36GP 40GP | ||||

Pin 3: Yellow Hall A | ||||||

Pin 4: Red Hall B | ||||||

Pin 5: Blue Hall C | ||||||

The motor data was measured in a standard test environment of 25 ° C. Motor operation beyond the maximum recommended continuous parameters may result in reduced life or damage to the motor. In high temperature environments, the load current must be reduced to protect the motor. | ||||||

Brushless motor Ball bearing | ||||||||

Model number | 2409 | 2407 | 3609 | 3607 | 4809 | 4807 | ||

Rated voltage | V | 24 | 24 | 36 | 36 | 48 | 48 | |

No-load speed ±12% | rpm | 9095 | 7074 | 9095 | 7074 | 9095 | 7074 | |

No-load current Max150% | mA | 375 | 292 | 250 | 150 | 188 | 146 | |

Recommended limit value for continuous operation | Maximum continuous torque | mN.m | 177.03 | 184.94 | 171.99 | 184.97 | 182.04 | 191.42 |

Rated speed | rpm | 8534 | 6425 | 8573 | 6539 | 8569 | 6530 | |

Maximum continuous current | mA | 7400 | 6000 | 4800 | 4000 | 3800 | 3100 | |

Rated power | W | 158.2 | 126.38 | 154.41 | 126.66 | 163.36 | 130.89 | |

Starting current | mA | 120000 | 77419 | 83721 | 52941 | 65753 | 40336 | |

Locked-rotor moment | mN.m | 3024 | 2508 | 3165 | 2573 | 3314 | 2614 | |

Maximum output power | W | 720 | 464.5 | 753.5 | 476.5 | 789 | 484 | |

Maximum efficiency value | % | 89 | 88 | 89 | 88 | 90 | 88 | |

End resistance ±12% | Ω | 0.22 | 0.31 | 0.43 | 0.68 | 0.7319 | 1.17 | |

inductance (1KHZ) | mH | 0.04 | 0.057 | 0.076 | 0.15 | 0.15 | 0.23 | |

Mechanical time constant | ms | 2.72 | 2.55 | 2.6 | 2.49 | 2.49 | 2.45 | |

Moment of inertia | gcm2 | 86.51 | 86.51 | 86.51 | 86.51 | 86.51 | 86.51 | |

Torque constant | mN.m/A | 25.2 | 32.4 | 37.8 | 48.6 | 50.4 | 64.8 | |

Speed constant | rpm/V | 379 | 295 | 253 | 196 | 189 | 147 | |

Speed/torque slope | rpm/mN.m | 3 | 2.8 | 2.9 | 2.7 | 2.7 | 2.7 | |

Motor weight | g | 356 | 356 | 356 | 356 | 356 | 356 | |

Relevant information | ||||||

Dynamic load: axial 6.0 N | Thermal time constant of motor 1163 S | |||||

Maximum installation force (static) 110 N | Dynamic load: radial (5mm outside face) 28.0 N | |||||

Maximum installation force (static) 110 N | Maximum driving depth of mounting screw 4.0mm | |||||

Radial clearance (5mm outside face) ≤0.02 mm | Axial clearance 0 (<6.0N ) | |||||

Maximum coil temperature 155ºC | Ambient temperature -30 to 65ºC | |||||

Standard rear axle diameter 5 mm | Standard rear axle Length "L" 0/3.7/5.5 mm | |||||

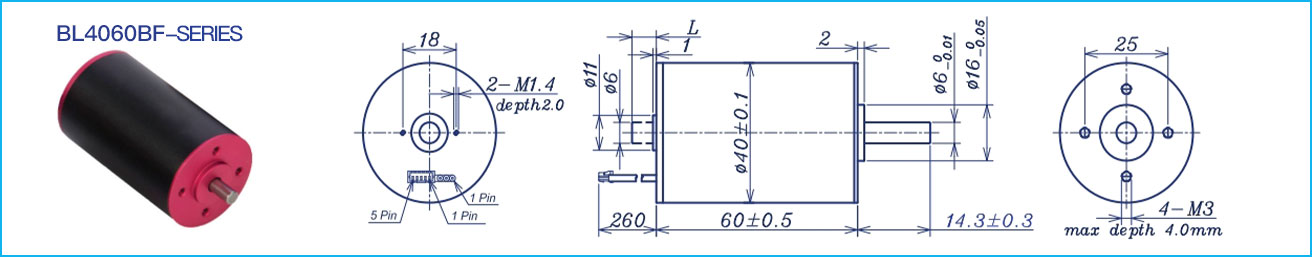

Lead Definition (AWG 20#)) | Total length of gear motor: LT=L1+L2+L3 | BL4060BF Recommended combination options | ||||

Lead 1: yellow motor winding A | L1:40GP | L1:45GP | L2:BL40 | L3:EN22S | L3:EN36T |

|

Lead 2: Red motor winding B | 35.3 | 36.1 | 60 | 10.7 | 12 | |

Lead 3: Blue motor winding C | 46.8 | 48.1 | ||||

Sensor Pin Definition (AWG 28#) Molex:51021-0500 | 58.3 | 60.1 | ||||

Pin 1: Brown Hall Vcc 3 to 16V | ||||||

Pin 2: Black Hall GND | Note: Customers can choose the corresponding gear box and encoder to match with the motor, more product combinations, please contact our sales staff. | Recommended gear box: 40GP 45GP | ||||

Pin 3: Yellow Hall A | ||||||

Pin 4: Red Hall B | ||||||

Pin 5: Blue Hall C | ||||||

The motor data was measured in a standard test environment of 25 ° C. Motor operation beyond the maximum recommended continuous parameters may result in reduced life or damage to the motor. In high temperature environments, the load current must be reduced to protect the motor. | ||||||

Brushless motor Ball bearing | ||||||||

Model number | 2407 | 2406 | 3608 | 3606 | 4808 | 4807 | ||

Rated voltage | V | 24 | 24 | 36 | 36 | 48 | 48 | |

No-load speed ±12% | rpm | 7569 | 5823 | 9200 | 5684 | 8200 | 7075 | |

No-load current Max150% | mA | 900 | 650 | 700 | 289 | 430 | 350 | |

Recommended limit value for continuous operation | Maximum continuous torque | mN.m | 354.79 | 358.2 | 234.3 | 381.69 | 276.39 | 230 |

Rated speed | rpm | 6397 | 5427 | 8812 | 5382 | 7350 | 6804 | |

Maximum continuous current | mA | 11000 | 9600 | 7000 | 6600 | 5000 | 3890 | |

Rated power | W | 237.68 | 203.55 | 216.2 | 215.12 | 214.25 | 163.86 | |

Starting current | mA | 218182 | 141176 | 149904 | 124138 | 165517 | 111628 | |

Locked-rotor moment | mN. m | 7423 | 5557 | 5549 | 7508 | 10010 | 7258 | |

Maximum output power | W | 1390.1 | 847.1 | 1336.6 | 1117.2 | 2149 | 1339.5 | |

Maximum efficiency value | % | 90 | 88 | 87 | 91 | 90 | 89 | |

End resistance ±12% | Ω | 0.11 | 0.17 | 0.16 | 0.29 | 0.29 | 0.43 | |

inductance (1KHZ) | mH | 0.023 | 0.043 | 0.035 | N/A | 0.082 | 0.13 | |

Mechanical time constant | ms | 2.16 | 2.49 | 3.9 | 1.8 | 1.8 | 1.71 | |

Moment of inertia | gcm2 | 227.14 | 227.14 | 227.14 | 227.14 | 227.14 | 227.14 | |

Torque constant | mN.m/A | 34.02 | 39.36 | 37.2 | 60.48 | 60.48 | 65.02 | |

Speed constant | rpm/V | 281 | 243 | 257 | 158 | 158 | 147 | |

Speed/torque slope | rpm/mN.m | 0.9 | 1 | 1.7 | 0.8 | 0.8 | 1 | |

Motor weight | g | 757 | 757 | 757 | 757 | 757 | 757 | |

Relevant information | ||||||

Thermal resistance of motor 3.3 K/W | Thermal time constant of motor 1740 S | |||||

Dynamic load: axial 6.0 N | Dynamic load: radial (5mm outside face) 180.0 N | |||||

Maximum installation force (static) 110 N | Maximum driving depth of mounting screw 4.5 mm | |||||

Radial clearance (5mm outside face) ≤0.02 mm | Axial clearance 0 (<8.0N ) | |||||

Maximum coil temperature 155ºC | Ambient temperature -30 to 65ºC | |||||

Standard rear axle diameter 8 mm | Standard rear axle Length "L" 0/3.7/5.5 mm | |||||

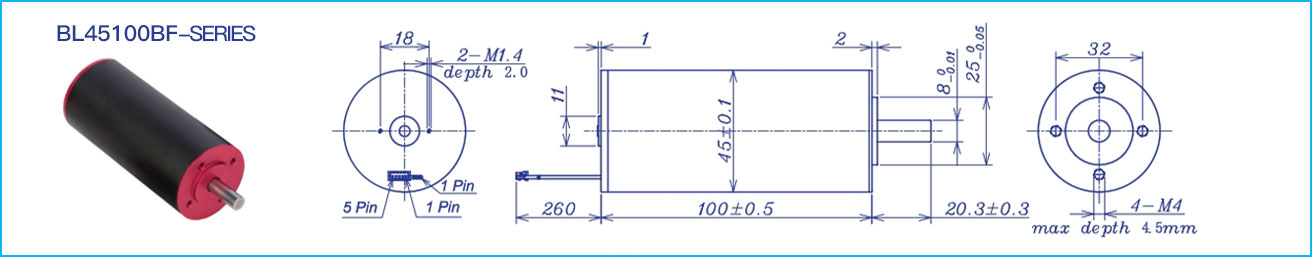

Lead Definition (AWG 18#)) | Total length of gear motor: LT=L1+L2+L3 | BL45100BF Recommended combination options | ||||

Lead 1: yellow motor winding A | L1:45GP | L1:52GP | L2:BL45 | L3:EN22S | L3:EN36T |

|

Lead 2: Red motor winding B | 60.1 | 79.3 | 100 | 10.7 | 12 | |

Lead 3: Blue motor winding C | 72.1 | |||||

Sensor Pin Definition (AWG 28#) Molex:51021-0500 | ||||||

Pin 1: Brown Hall Vcc 3 to 16V | ||||||

Pin 2: Black Hall GND | Note: Customers can choose the corresponding gear box and encoder to match with the motor, more product combinations, please contact our sales staff. | Recommended gear box: 45GP 52GP | ||||

Pin 3: Yellow Hall A | ||||||

Pin 4: Red Hall B | ||||||

Pin 5: Blue Hall C | ||||||

The motor data was measured in a standard test environment of 25 ° C. Motor operation beyond the maximum recommended continuous parameters may result in reduced life or damage to the motor. In high temperature environments, the load current must be reduced to protect the motor. | ||||||

Application

High power series of DC hollow cup brushless motors play a key role in many industries.

In the field of industrial manufacturing, heavy machinery drives for automated production lines, such as large robotic arms and high-load conveyor belts, ensure efficient

production with powerful power; In the logistics industry, it helps the high-speed operation of sorting robots and the handling of heavy goods to improve the efficiency

of sorting and transportation.

In transportation, it can be applied to electric forklift trucks, AGV cars and other equipment to provide strong power to meet the needs of frequent start and stop and high

load operation. In the medical equipment industry, it is suitable for high-precision motion control of large image diagnostic equipment to ensure stable and accurate operation

of equipment.

In addition, in scientific research and experimental equipment, it provides stable and strong power support for high-precision centrifuges, large vacuum coating equipment, etc.,

to help the smooth development of scientific research. These industries have high requirements for motor power, and this series of motors has become a powerful "engine" to

promote the development of various industries with its excellent performance.