Product Description

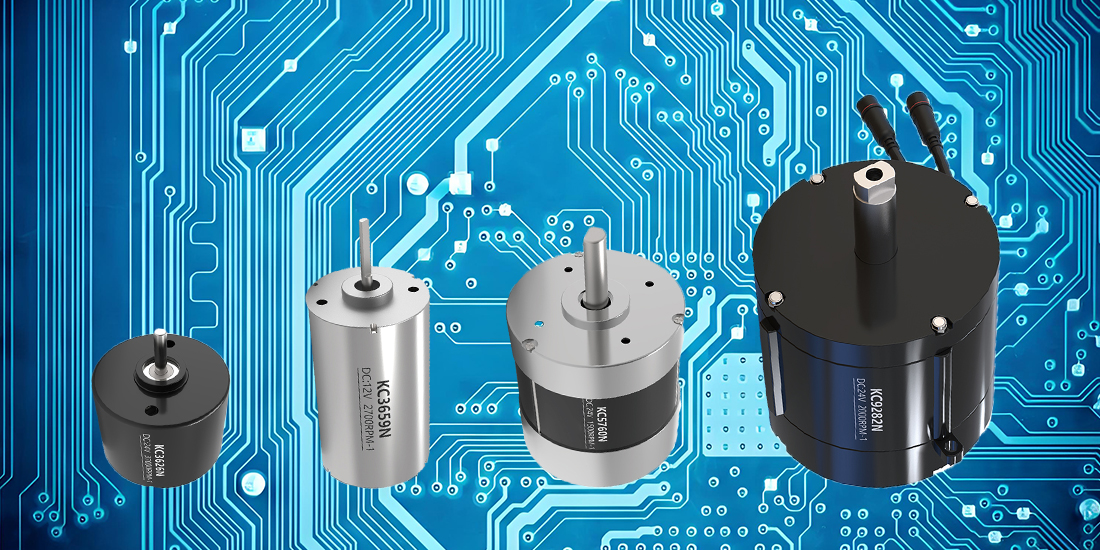

The internal rotor brushless motor, with its unique design and advanced technology, is excellent in many fields. The rotor rotates in the stator, the moment of inertia is small, can respond quickly to the command, to achieve accurate start and stop and speed control, suitable for the dynamic response requirements of the equipment. The motor uses electronic commutation instead of mechanical commutation, eliminating friction and sparks between brush and commutator, reducing energy loss, improving conversion efficiency, and reducing maintenance needs and costs. Moreover, the heat dissipation performance of the motor is excellent, the heat generated during operation can be quickly dissipated, and can work stably for a long time to ensure the continuous operation of the equipment. In addition, the internal rotor brushless motor has minimal noise and vibration during operation, providing quiet and stable power support for noise-sensitive environments, such as medical equipment and household silent appliances.

Product parameters

Model number | voltage | NO LOAD | LOAD | locked-rotor | ||||

Electric current(A) | Rotational speed(rpm) | Moment of force(gf.cm) | Electric current(A) | Rotational speed(rpm) | Electric current(A) | Moment of force(gf.cm) | ||

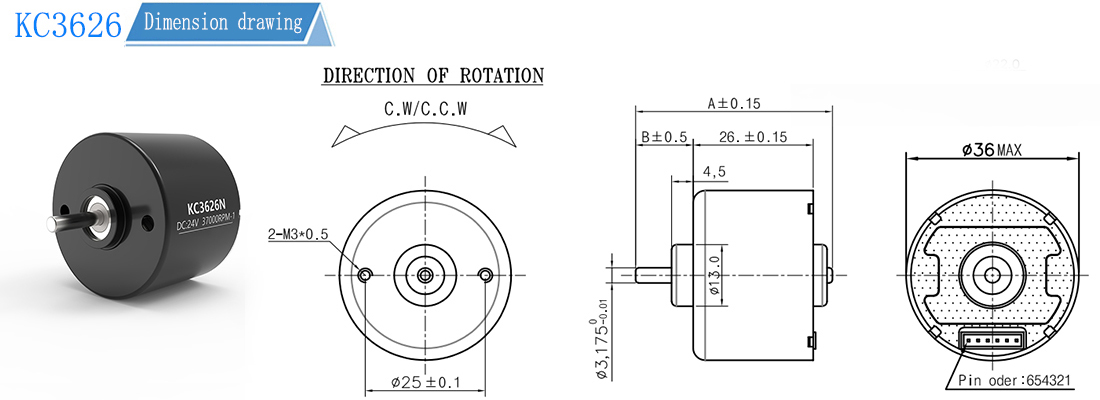

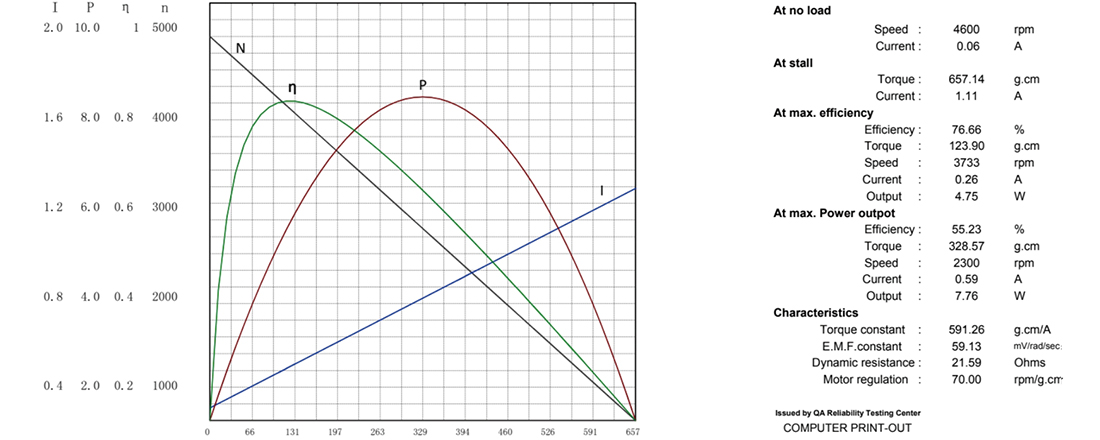

KC-3626 | 12 | 0.08 | 4070 | 200 | 0.65 | 3060 | 2.4 | 800 |

KC-3626 | 36 | 0.26 | 19400 | 220 | 1.3 | 16700 | 7.7 | 1580 |

Model number | voltage | NO LOAD | LOAD | locked-rotor | ||||

Electric current(A) | Rotational speed(rpm) | Moment of force(gf.cm) | Electric current(A) | Rotational speed(rpm) | Electric current(A) | Moment of force(gf.cm) | ||

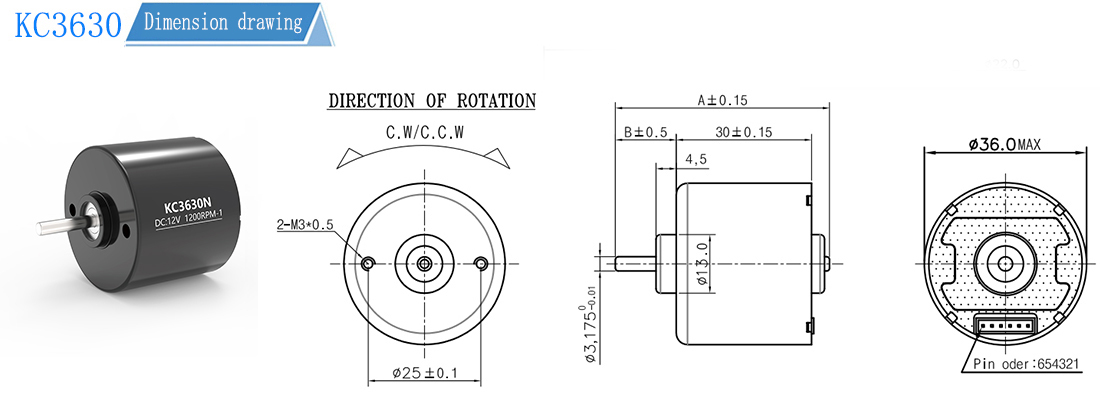

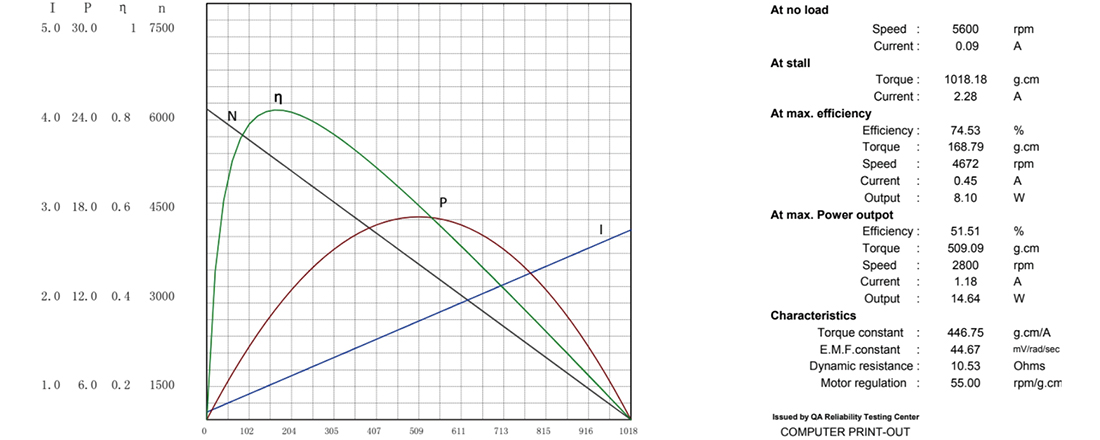

KC-3630 | 24 | 0.09 | 5600 | 200 | 0.52 | 4500 | 2.2 | 1000 |

Model number | voltage | NO LOAD | LOAD | locked-rotor | ||||

Electric current(A) | Rotational speed(rpm) | Moment of force(gf.cm) | Electric current(A) | Rotational speed(rpm) | Electric current(A) | Moment of force(gf.cm) | ||

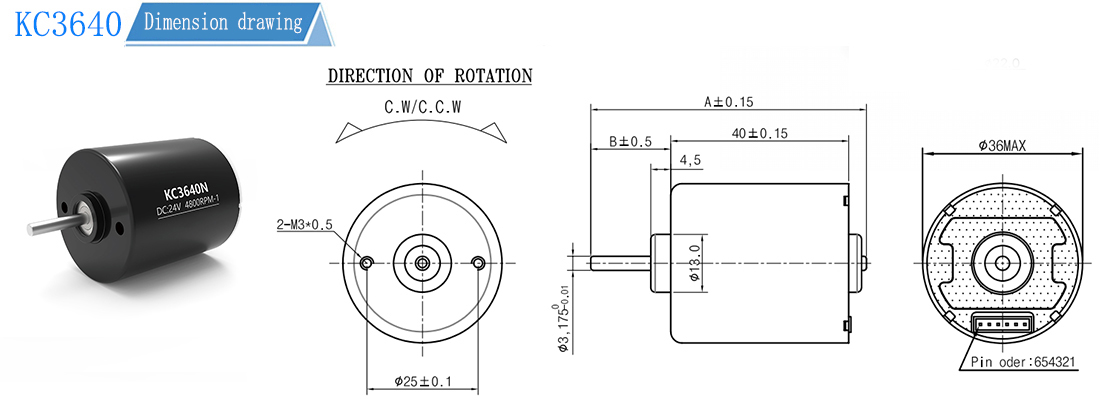

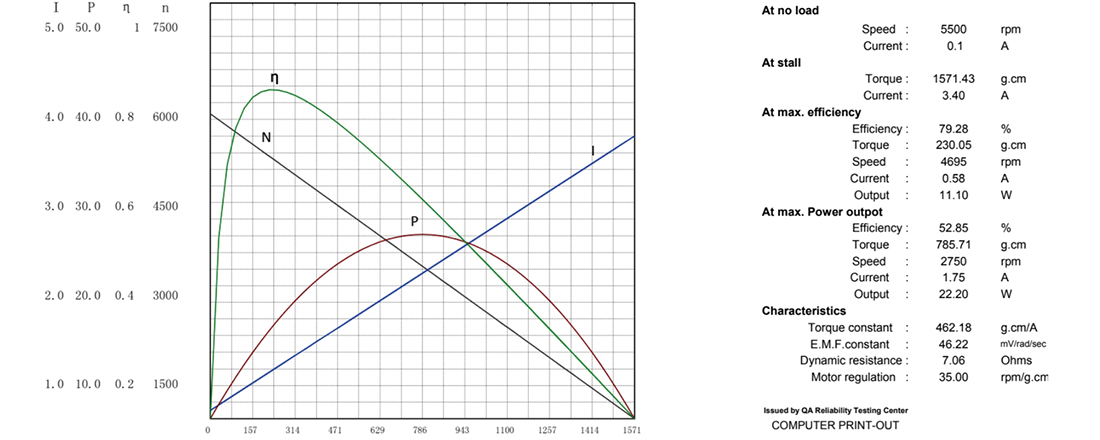

KC-3640 | 24 | 0.08 | 5500 | 200 | 0.52 | 4800 | 2.9 | 1400 |

Model number | voltage | NO LOAD | LOAD | locked-rotor | ||||

Electric current(A) | Rotational speed(rpm) | Moment of force(gf.cm) | Electric current(A) | Rotational speed(rpm) | Electric current(A) | Moment of force(gf.cm) | ||

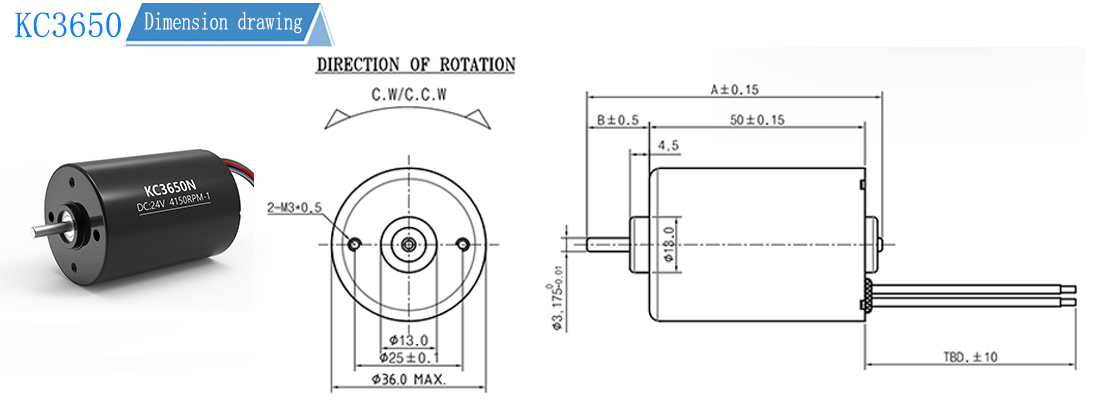

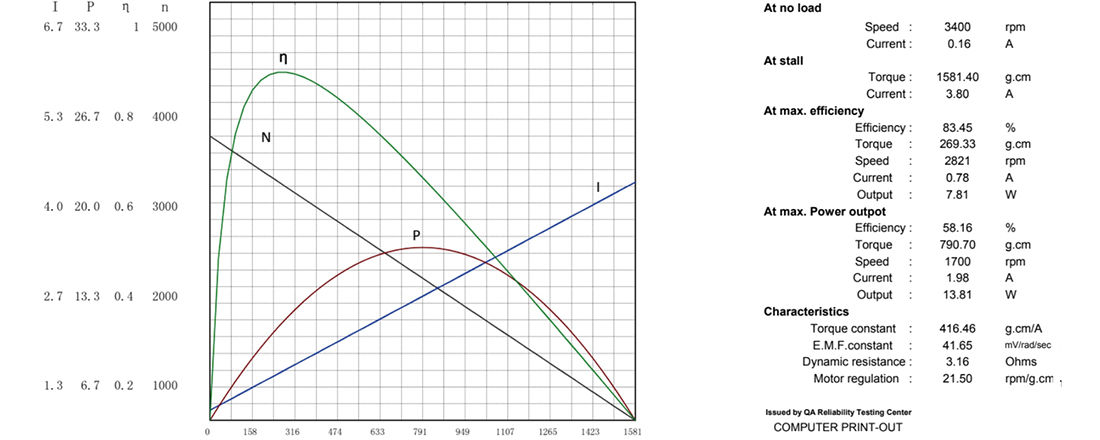

KC-3650 | 12 | 0.16 | 3400 | 200 | 0.6 | 2970 | 3.5 | 1520 |

Model number | voltage | NO LOAD | LOAD | locked-rotor | ||||

Electric current(A) | Rotational speed(rpm) | Moment of force(gf.cm) | Electric current(A) | Rotational speed(rpm) | Electric current(A) | Moment of force(gf.cm) | ||

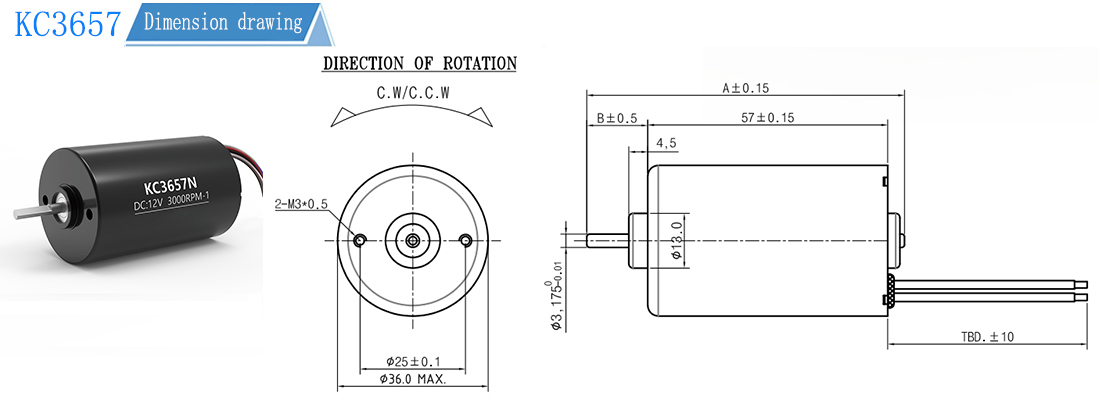

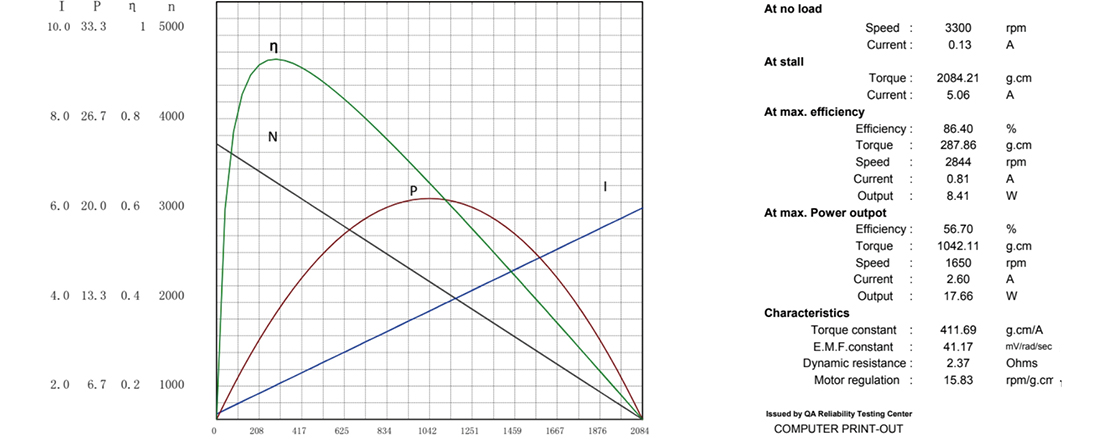

KC-3657 | 12 | 0.13 | 3300 | 600 | 1.5 | 2350 | 3 | 200 |

KC-3657 | 14.4 | 0.96 | 20600 | 200 | 3.7 | 18060 | 23 | 1622 |

Model number | voltage | NO LOAD | LOAD | locked-rotor | ||||

Electric current(A) | Rotational speed(rpm) | Moment of force(gf.cm) | Electric current(A) | Rotational speed(rpm) | Electric current(A) | Moment of force(gf.cm) | ||

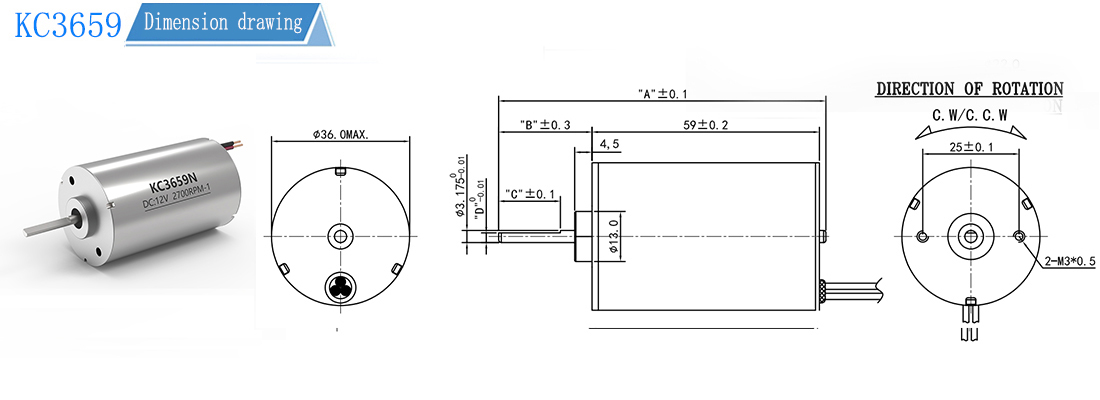

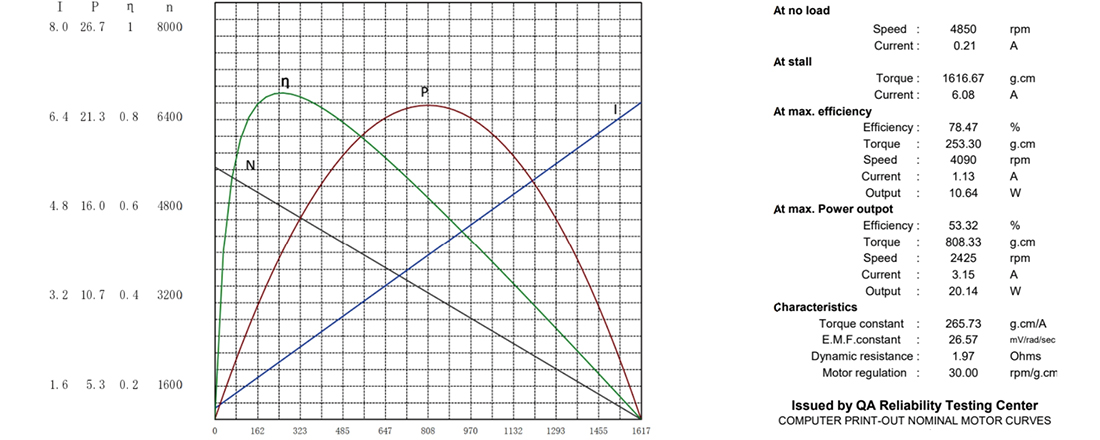

KC-3659 | 12 | 0.14 | 2700 | 300 | 0.73 | 2150 | 2.9 | 1350 |

Model number | voltage | NO LOAD | LOAD | locked-rotor | ||||

Electric current(A) | Rotational speed(rpm) | Moment of force(gf.cm) | Electric current(A) | Rotational speed(rpm) | Electric current(A) | Moment of force(gf.cm) | ||

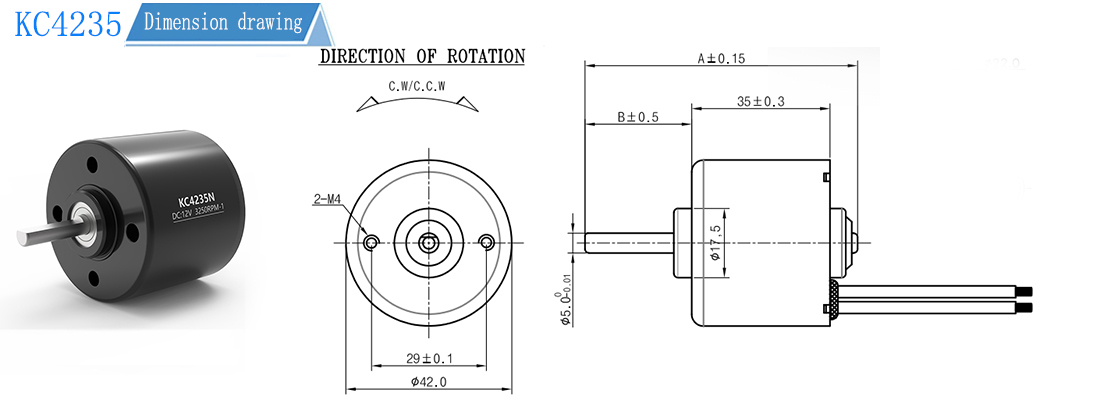

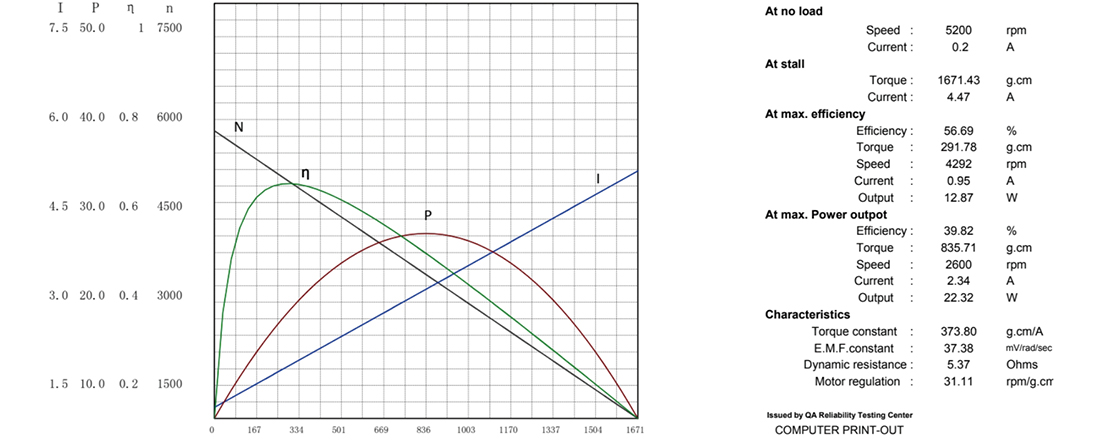

KC-4235 | 24 | 0.2 | 5200 | 600 | 1.5 | 3800 | 4.5 | 1500 |

Model number | voltage | NO LOAD | LOAD | locked-rotor | ||||

Electric current(A) | Rotational speed(rpm) | Moment of force(gf.cm) | Electric current(A) | Rotational speed(rpm) | Electric current(A) | Moment of force(gf.cm) | ||

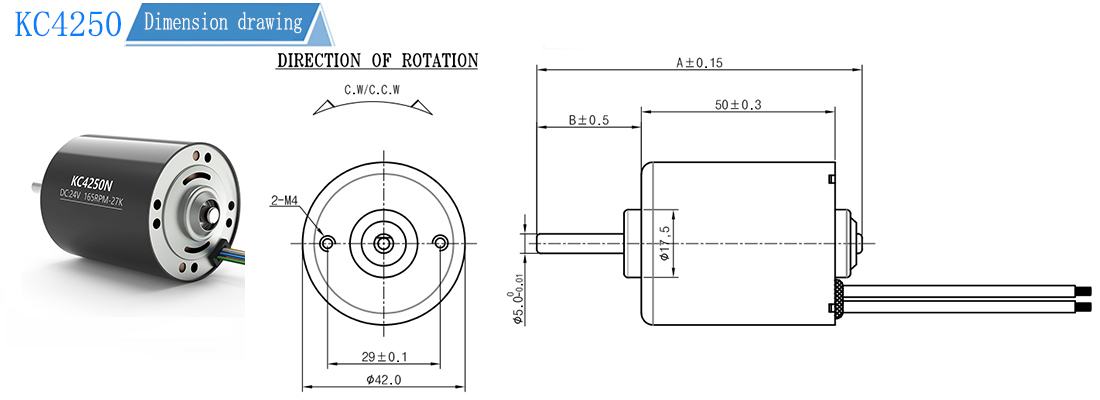

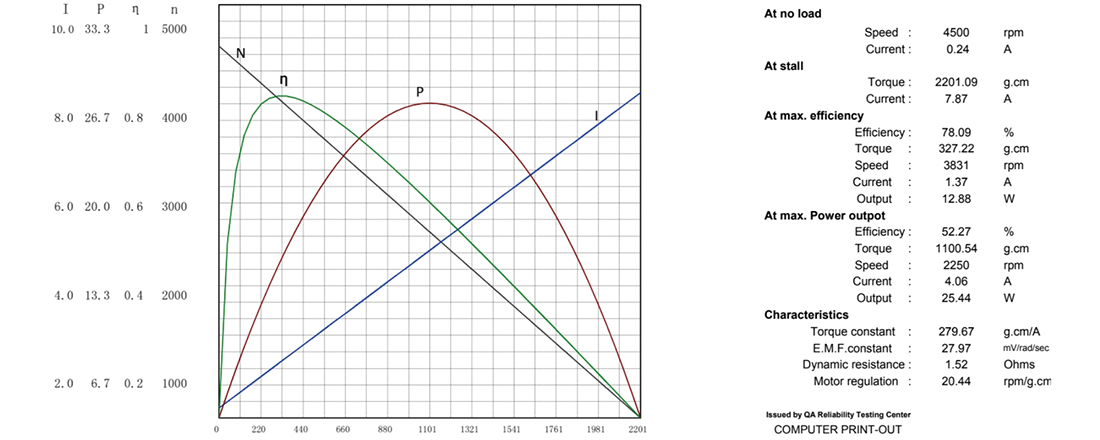

KC-4250 | 12 | 0.24 | 4500 | 450 | 1.8 | 3580 | 4.5 | 2200 |

Model number | voltage | NO LOAD | LOAD | locked-rotor | ||||

Electric current(A) | Rotational speed(rpm) | Moment of force(gf.cm) | Electric current(A) | Rotational speed(rpm) | Electric current(A) | Moment of force(gf.cm) | ||

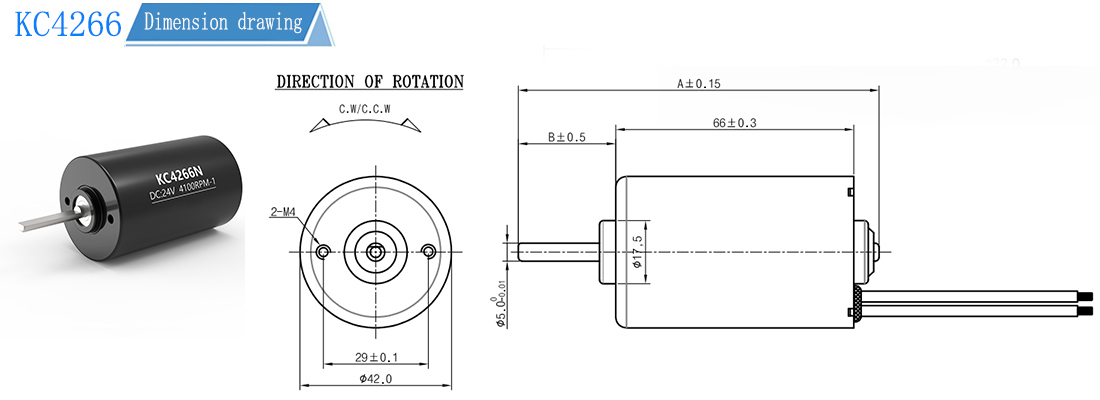

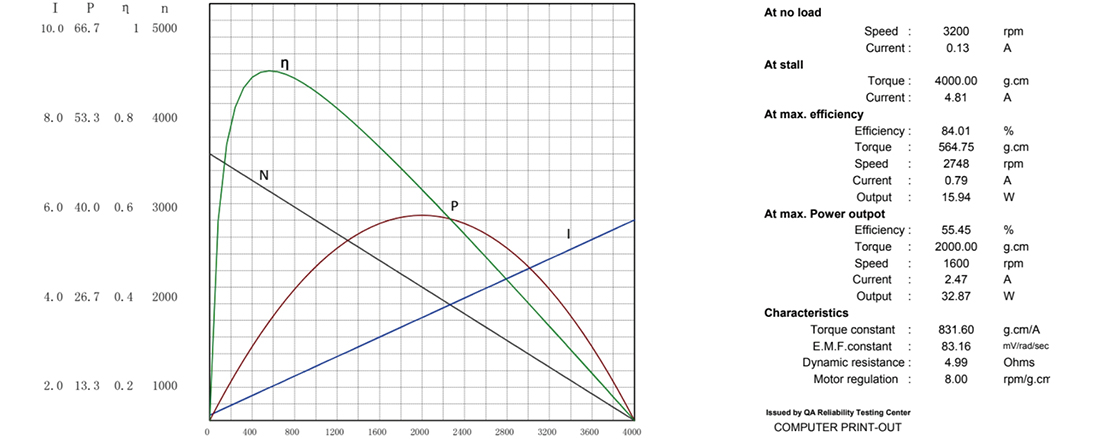

KC-4266 | 24 | 0.13 | 3200 | 1000 | 1.3 | 2400 | 4.8 | 3980 |

Model number | voltage | NO LOAD | LOAD | locked-rotor | ||||

Electric current(A) | Rotational speed(rpm) | Moment of force(gf.cm) | Electric current(A) | Rotational speed(rpm) | Electric current(A) | Moment of force(gf.cm) | ||

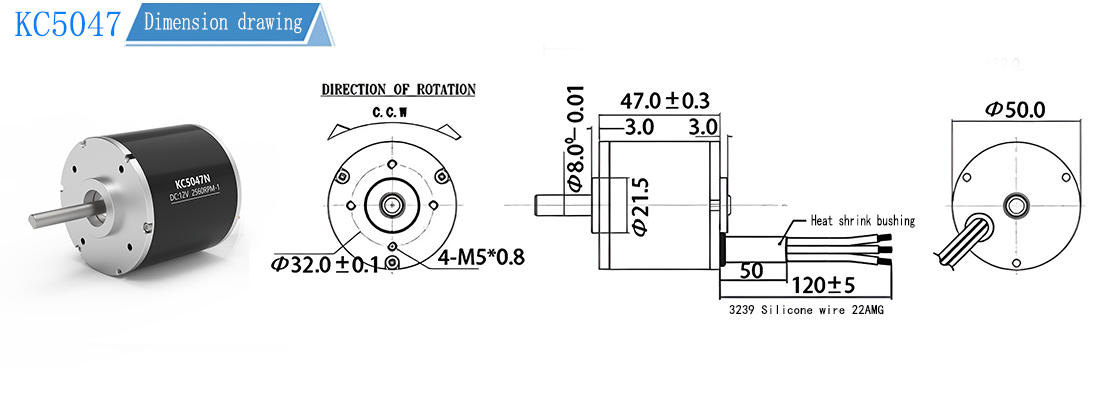

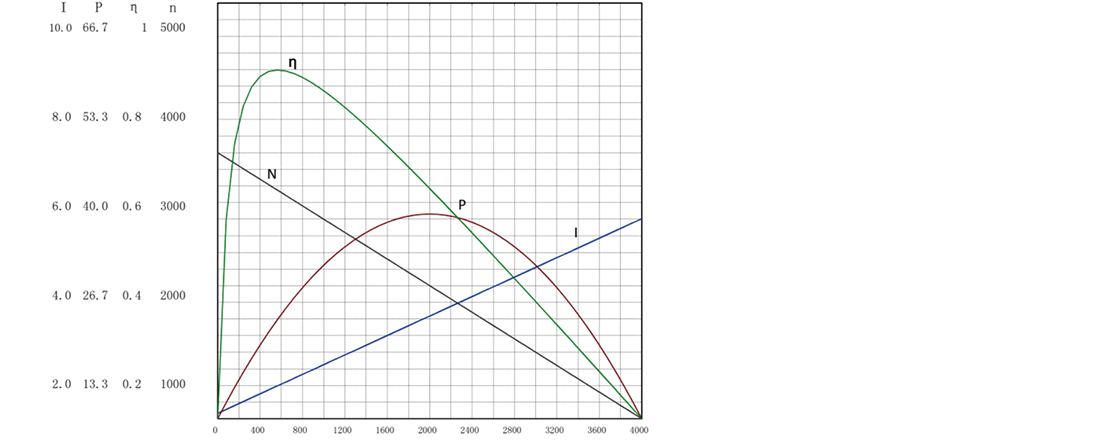

KC-5047 | 12 | 0.26 | 3000 | 1050 | 3 | 2560 | 8 | 3000 |

Model number | voltage | NO LOAD | LOAD | locked-rotor | ||||

Electric current(A) | Rotational speed(rpm) | Moment of force(gf.cm) | Electric current(A) | Rotational speed(rpm) | Electric current(A) | Moment of force(gf.cm) | ||

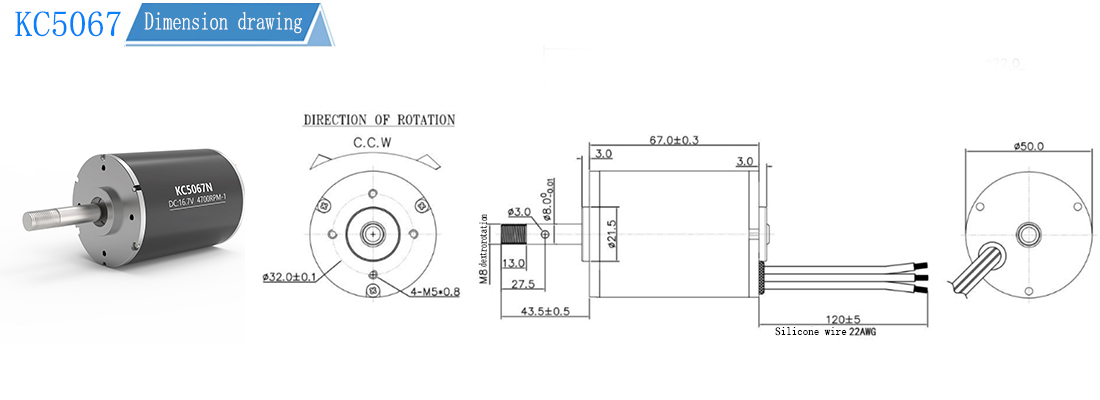

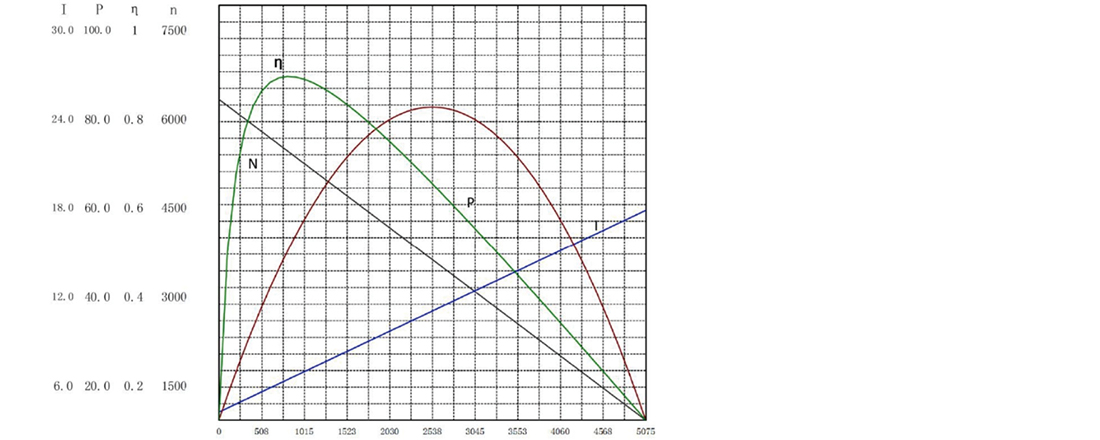

KC-5067 | 24 | 0.25 | 3400 | 2025 | 3.1 | 3400 | 10 | 5900 |

Model number | voltage | NO LOAD | LOAD | locked-rotor | ||||

Electric current(A) | Rotational speed(rpm) | Moment of force(gf.cm) | Electric current(A) | Rotational speed(rpm) | Electric current(A) | Moment of force(gf.cm) | ||

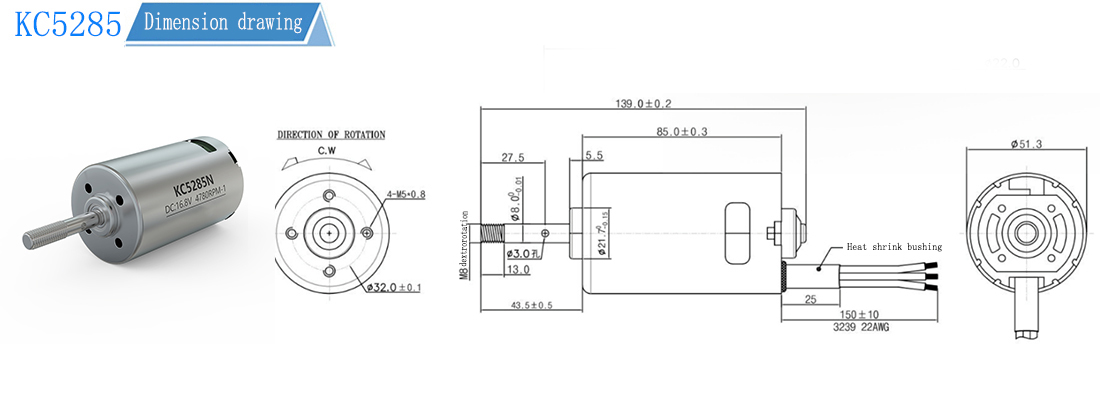

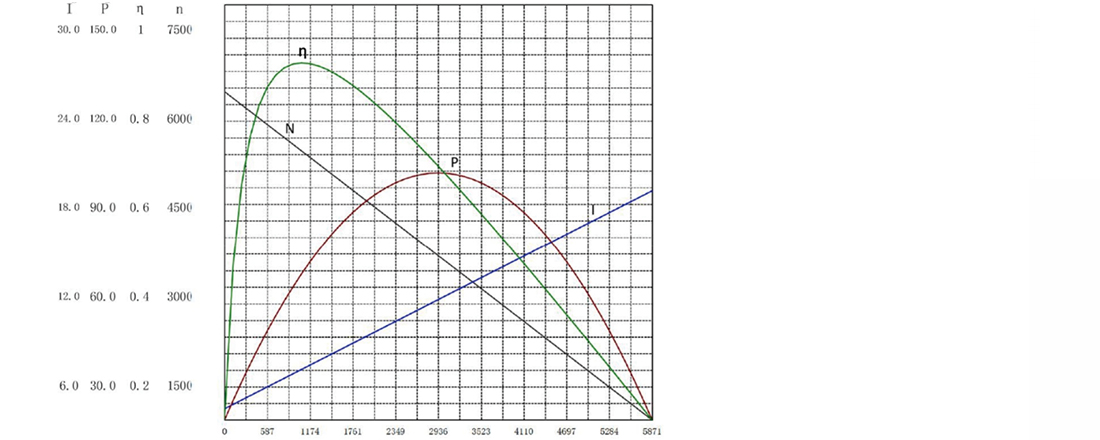

KC-5285 | 16.8 | 0.8 | 4833 | 1050 | 3.63 | 4782 | 24.8 | 10577 |

Model number | voltage | NO LOAD | LOAD | locked-rotor | ||||

Electric current(A) | Rotational speed(rpm) | Moment of force(gf.cm) | Electric current(A) | Rotational speed(rpm) | Electric current(A) | Moment of force(gf.cm) | ||

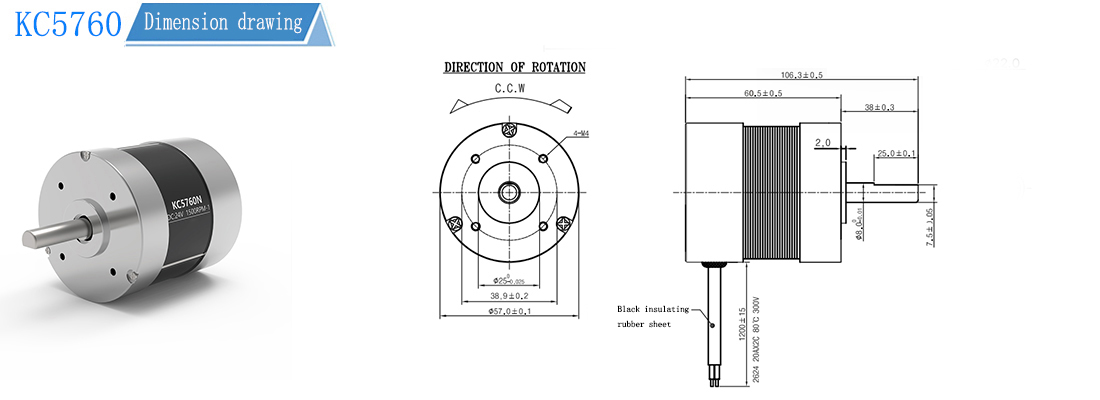

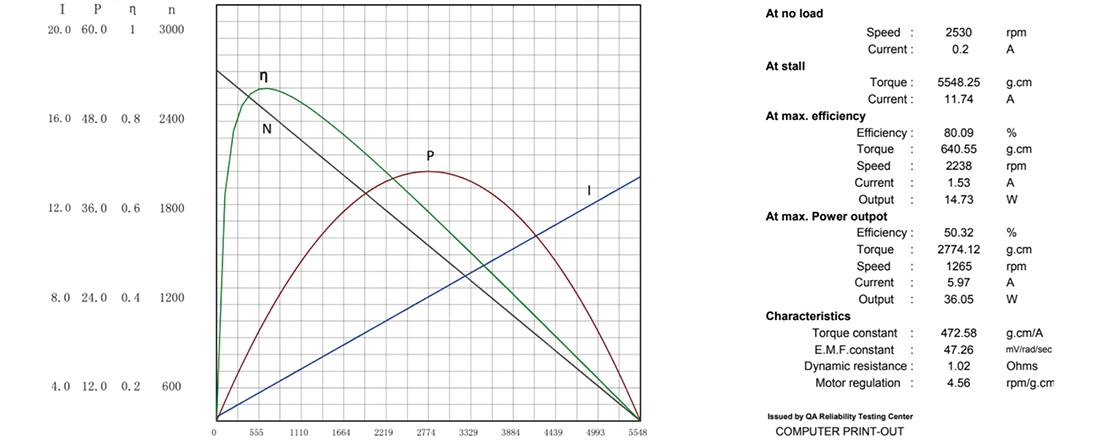

KC-5760 | 12 | 0.2 | 2530 | 1250 | 2.8 | 1960 | 11.7 | 5548 |

Model number | voltage | NO LOAD | LOAD | locked-rotor | ||||

Electric current(A) | Rotational speed(rpm) | Moment of force(gf.cm) | Electric current(A) | Rotational speed(rpm) | Electric current(A) | Moment of force(gf.cm) | ||

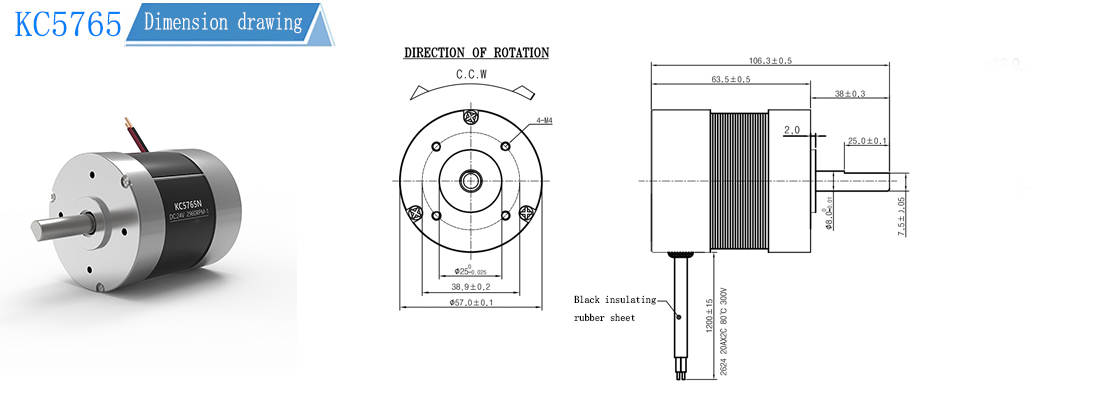

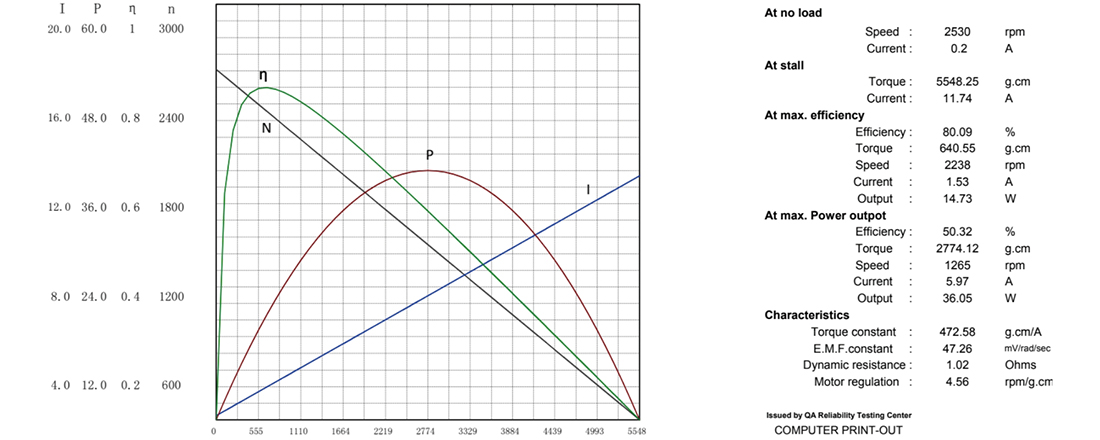

KC-5765 | 12 | 0.2 | 2530 | 1250 | 2.8 | 1960 | 11.7 | 5548 |

Model number | voltage | NO LOAD | LOAD | locked-rotor | ||||

Electric current(A) | Rotational speed(rpm) | Moment of force(gf.cm) | Electric current(A) | Rotational speed(rpm) | Electric current(A) | Moment of force(gf.cm) | ||

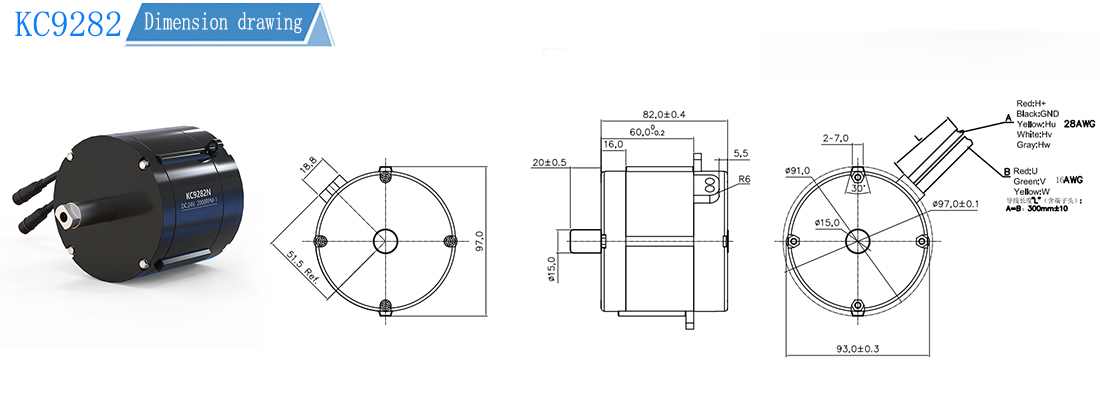

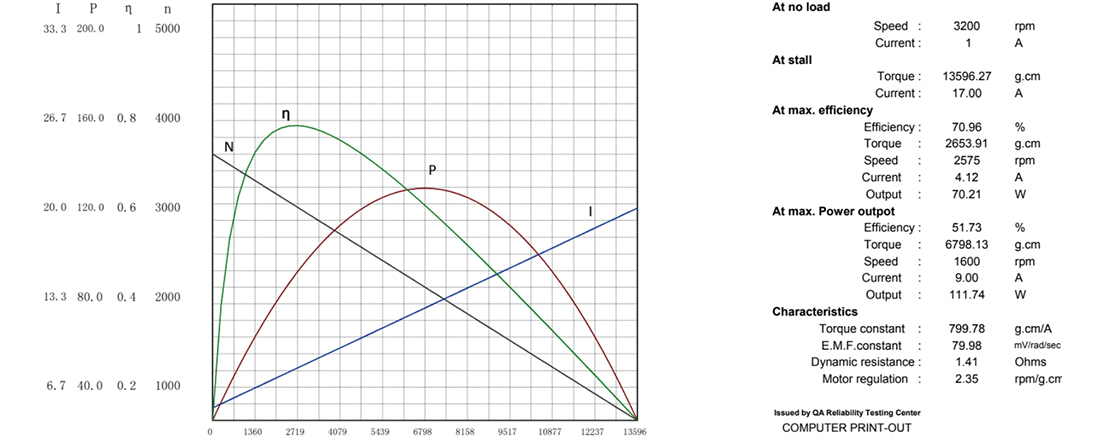

KC-9282 | 24 | 1 | 3200 | 5098.6 | 7 | 2000 | 17 | 13596.2 |

Custom Process

Pre-sales consultation

Scheme discussion

Scheme determination

Processing and production

Logistics delivery

After-sales service

Application