Product Description

The precise control advantages of the C series of 42mm-63mm external rotor brushless motors

Functional Features

·14 Pole Hi-torque rotor design,stable output power.

·Fits all fixed wing aircraft model.

·CNC Machined 6061 T6 aluminum front and rear cover.

·High purity copper windings maximizes efficiency.

·Explosion-proof rotor,high toughness stainless steel shaft,high precision and high quality bearing make the motor super durable.

·Preclslon balanced rotor,smoothness for best rellablllty and maximum RPM.

Product parameters

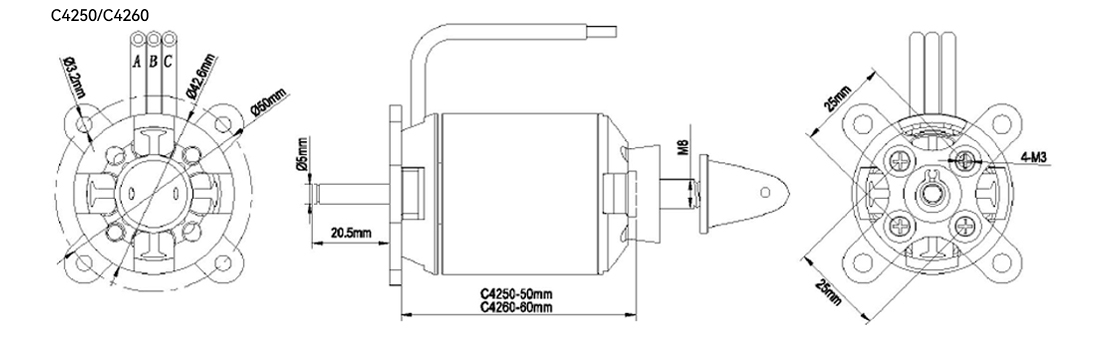

42 Diameter series |

Model | Item Number | KV | MAXWatts | Voltage | Max | Rotor | No load | Resistance | Motor Size | Stator | Weight | Propeller |

C4250-06 | SP-042500-01 | 800 | 1250 | 10~20 | 62 | 14 | 2.3 | 0.0212 | φ42x50 | φ35x20 | 205 | 13x10/14x7/14x10 |

C4250-07 | 720 | 1120 | 10~20 | 56 | 14 | 1.8 | 0.0298 | φ42x50 | φ35x20 | 205 | 13x8/14x7/12x10 | |

C4260-05 | SP-042600-01 | 710 | 1650 | 10~20 | 82 | 14 | 2.7 | 0.0234 | φ42x60 | φ35x30 | 275 | 13x10/14x10/15x8 |

C4260-06 | 600 | 1500 | 10~20 | 75 | 14 | 2.1 | 0.0291 | φ42x60 | φ35x30 | 275 | 15x8/16x8/16x10 |

50 Diameter series |

Model | Item Number | KV | MAXWatts | Voltage | Max | Rotor | No load | Resistance | Motor Size | Stator | Weight | Propeller |

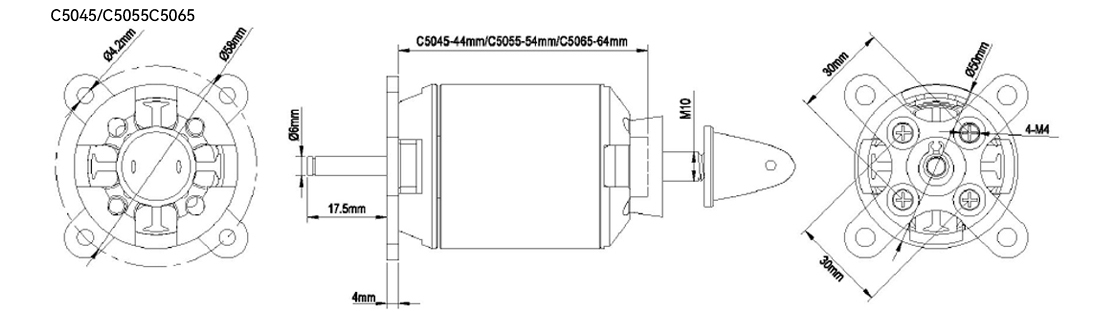

C5045-9T | SP-050450-01 | 890 | 860 | 10~18 | 48 | 14 | 2.5 | 0.0215 | φ50x44 | φ41x10 | 195 | 12x6/13x10/13x8 |

C5045-10.5T | 720 | 860 | 10~20 | 43 | 14 | 1.6 | 0.0275 | φ50x44 | φ41x10 | 195 | 14x7/12x10/13x8 | |

C5055-06 | SP-050550-01 | 760 | 1660 | 10~20 | 83 | 14 | 2.4 | 0.0173 | φ50x54 | φ41x20 | 275 | 14x8/15x8/17x9 |

C5055-08 | 570 | 1550 | 15~24 | 65 | 14 | 1.5 | 0.0255 | φ50x54 | φ41x20 | 275 | 14x8/15x8/17x9 | |

C5065-07 | SP-050650-01 | 435 | 1750 | 15~24 | 73 | 14 | 1.6 | 0.0234 | φ50x64 | φ41x30 | 375 | 16x8/16x10/17x9 |

C5065-09 | 335 | 1600 | 15~30 | 53 | 14 | 1.2 | 0.0421 | φ50x64 | φ41x30 | 375 | 16x10/18x10/18.5x12 |

63 Diameter series |

Model | Item Number | KV | MAXWatts | Voltage | Max | Rotor | No load | Resistance | Motor Size | Stator | Weight | Propeller |

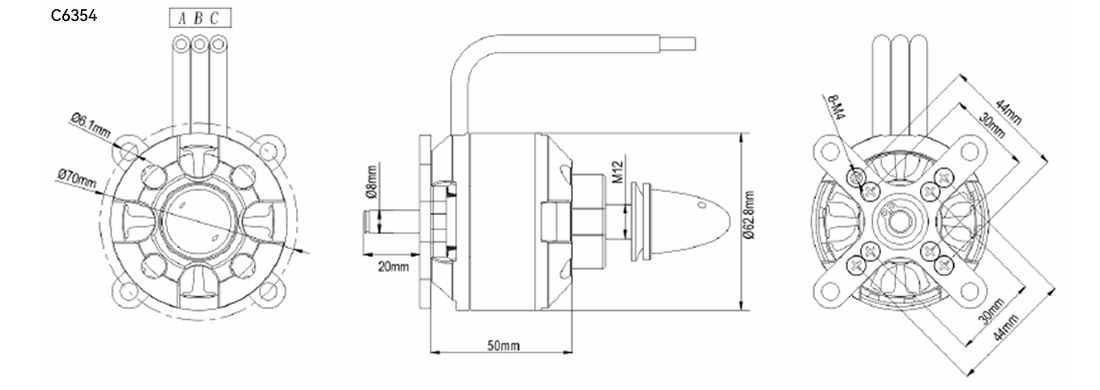

C6354-14 | SP-063540-01 | 245 | 2100 | 15~42 | 55 | 14 | 1.5 | 0.0059 | φ63x50 | φ53x20 | 480 | 19x12/20x10/18.5x12 |

C6354-16 | 200 | 2210 | 15~42 | 50 | 14 | 0.9 | 0.0074 | φ63x50 | φ53x20 | 480 | 19x10/19x12/18.5x12 |

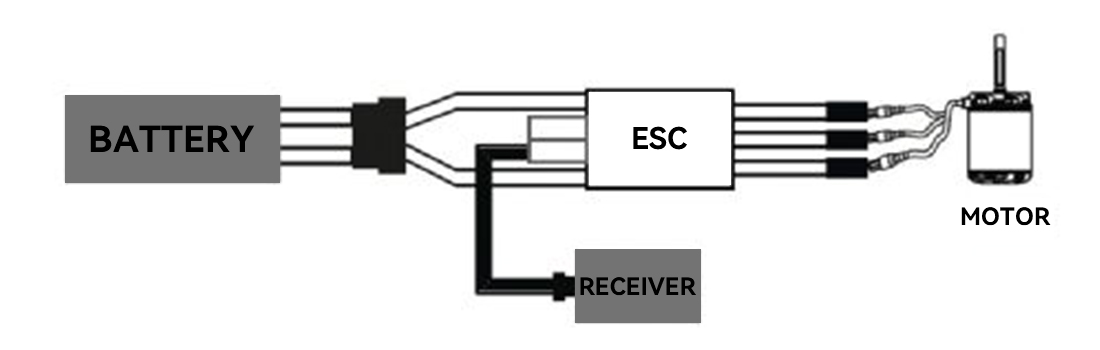

Application wiring diagram

1. Install the motor

The motor mounting screw holes are M3(C28,C35,C42 series)/M4(C50,C63 series) screws.

2. Motor connection

There is no strict line sequence requirement for the motor and the electrical connection, and the #A/#B/#C of the motor can be docking with the three lines of the electrical adjustment at will, if the reverse direction occurs, the two motor lines can be exchanged at will.

3. Check

Before turning on the power supply of the remote control model, be sure to double check the correctness of the power system connection and the reliability of the installation.

Application

It is widely applied to: unmanned aerial vehicles, fixed-wing aircraft, model cars, model ships, power tools, robots, etc

Service

Dedicated service, along the way

Warranty worry-free, extended repair, often return to promote optimization, peace of mind choice, all in control.

Before the purchase of professional consultants rapid response, accurate recommendation products;

Purchase logistics is efficient, specially-assigned to ensure delivery;

After the purchase 7×24 hours customer service answer questions, engineers at any time to save the "machine";

After-sale guarantee

After-sales service: We provide comprehensive after-sales technical support, if you encounter any problems in the process of use, the professional after-sales engineer team will respond quickly, through telephone, mail or remote assistance, to provide you with detailed solutions. We also provide regular return visits to our products to understand how they are used and to collect your feedback in order to continuously optimize our products and services. In addition, in strict accordance with the quality assurance policy, we provide free repair or replacement services for products with quality problems during the warranty period, so that you have no worries.