Product Description

The SpeedArm S20X is a powerful and compact 4-axis SCARA (Selective Compliance Articulated Robot Arm) robot, engineered for high-speed, high-precision automation tasks. With a robust 20kg payload and an 820mm working radius, it delivers exceptional performance for material handling, pick-and-place, assembly, and packaging applications across diverse industries.

Featuring a repeatability of ±0.02mm (Axis 1+2) and IP30/IP54 protection, the SpeedArm S20X is ideal for clean and semi-harsh environments. It meets CE and ISO9001 certifications, ensuring compliance with international standards and reliability for global deployment. Its lightweight yet rigid frame makes it suitable for integration in compact spaces while delivering consistent speed and precision.

Application

| Industry | Typical Applications |

| 3C (Computer, Communication, Consumer Electronics) | Assembly of electronic components, pick-and-place of delicate parts |

| Pharmaceutical Manufacturing | Bottle capping, blister packaging, product sorting |

| Food Processing | Pick-and-place packaging, sorting items on conveyor lines |

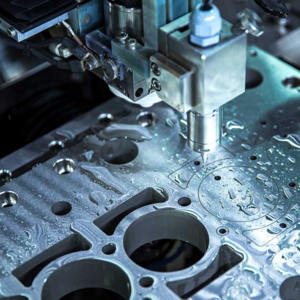

| Machining / Metalworking | Loading/unloading CNC machines, precise material transfer |

| Semiconductor Assembly | Wafer handling, IC packaging, test socket loading |

| Medical Devices | Precision assembly of instruments, packaging sterile components |

Product Features

High Payload with Compact Footprint

Despite its small structure, the SpeedArm S20X supports a 20kg payload and 820mm reach, offering high flexibility without compromising strength or precision.

Benefits: Increases line efficiency in small spaces; perfect for heavier parts and batch operations.

Use Cases: Machining part loading, packaging of bulk products, industrial tray handling.

Excellent Repeatability and Protection Design

With ±0.02mm repeatability (Axis 1+2) and up to IP54 ingress protection, the robot ensures dependable operation in controlled and semi-dusty environments.

Benefits: Reliable for precise, repetitive tasks in demanding applications.

Use Cases: Cleanroom use in electronics, moisture-protected operations in food or pharma packaging.

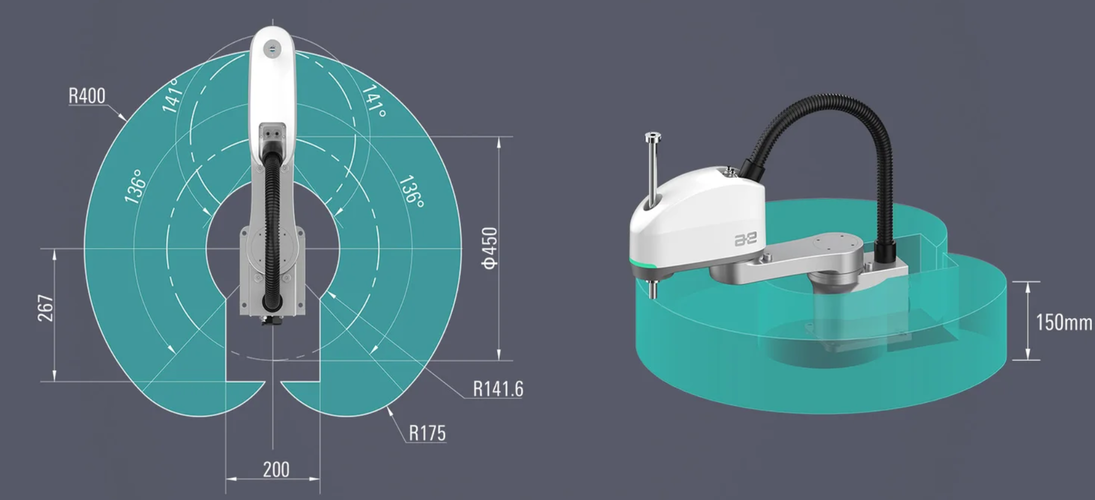

Structure Diagram

Product parameters

| Specification | Detail | Specification | Detail |

| Model | SpeedArm S20X | Speed | High-speed operation (customizable) |

| Type | 4-Axis SCARA Robot | Ingress Protection | IP30 standard / Up to IP54 optional |

| Payload Capacity | Up to 20kg | Certifications | CE, ISO9001 |

| Reach Radius | 820 mm (Range: 400–1000 mm) | Weight | Lightweight (specific weight on request) |

| Repeatability | ±0.02 mm (Axis 1+2) | Mounting Options | Floor or tabletop mounting |

| Degrees of Freedom (DOF) | 4 | Control Interface | PLC, PC, or proprietary controller |

Customer Case

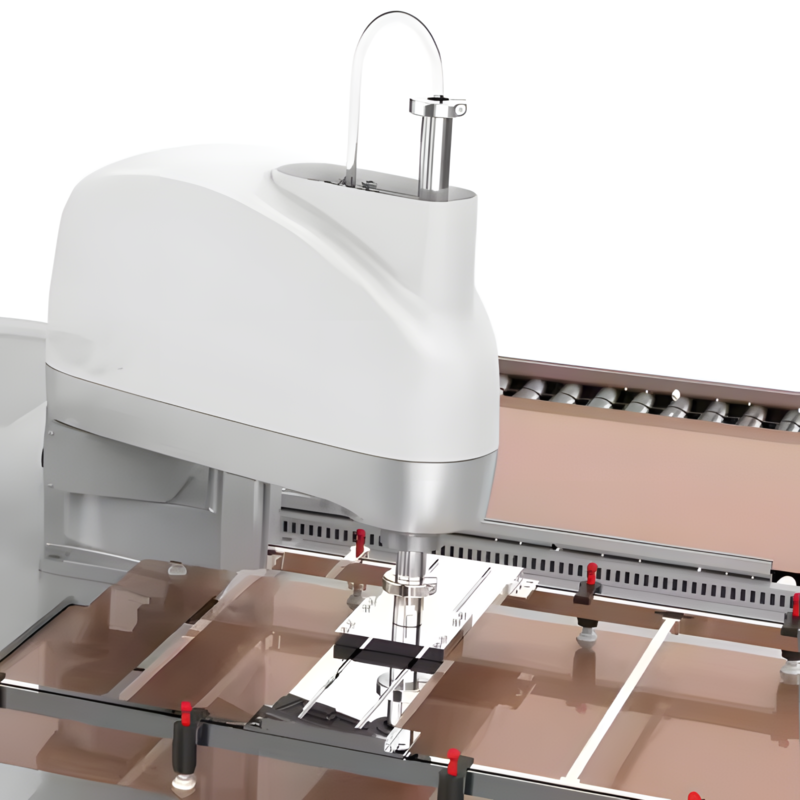

CNC Machine Loading in Metalworking Shop

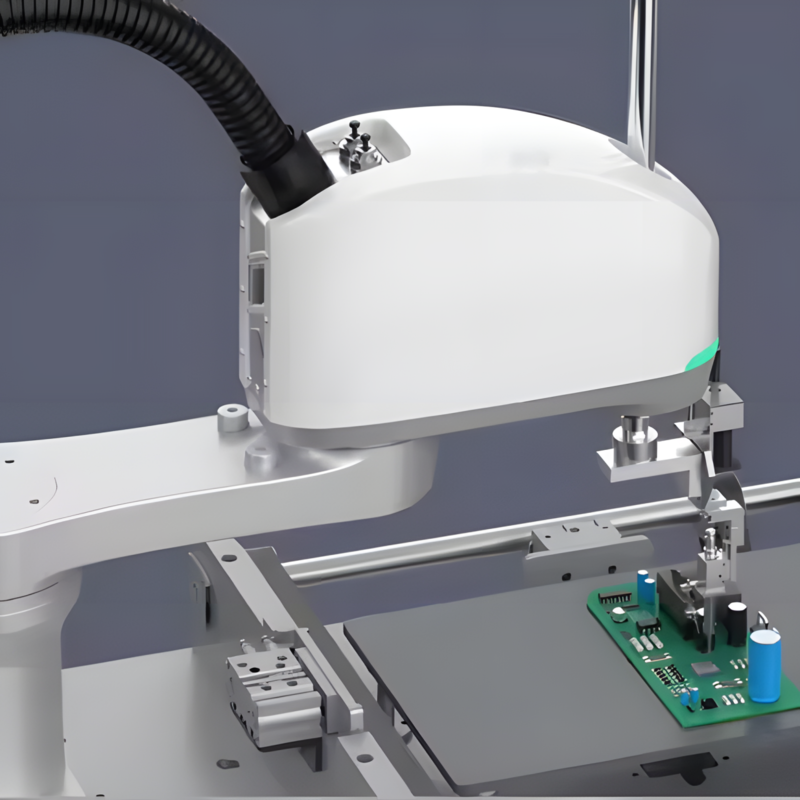

Blister Packaging Line in Pharmaceuticals

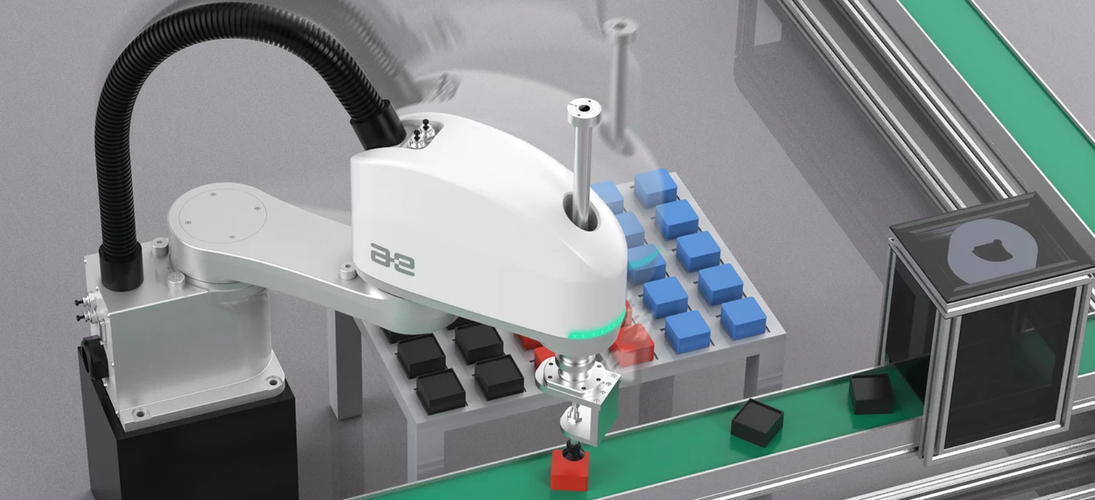

Food Sorting & Packaging Line

FAQ

Q1: What’s the maximum payload the SpeedArm S20X can handle safely?

A: The maximum payload is 20kg, including the weight of any attached end-effector or tooling.

Q2: Is the robot suitable for use in wet or dusty environments?

A: Yes, the robot offers IP30 as standard, and an optional IP54 configuration for drip-proof and dust-proof environments such as food and pharmaceutical applications.

Q3: Can I integrate it with my existing PLC or SCADA system?

A: Absolutely. The SpeedArm S20X supports standard industrial communication protocols such as Modbus, Ethernet/IP, and can interface easily with most PLC/SCADA systems.

Q4: Is programming difficult for new operators?

A: No, the robot is designed with user-friendly software and supports graphical programming interfaces, allowing even novice users to set up and run tasks quickly.

Q5: What certifications does the SpeedArm S20X have?

A: It is certified with CE and ISO9001, meeting international safety and quality management standards, ensuring reliability for global markets.