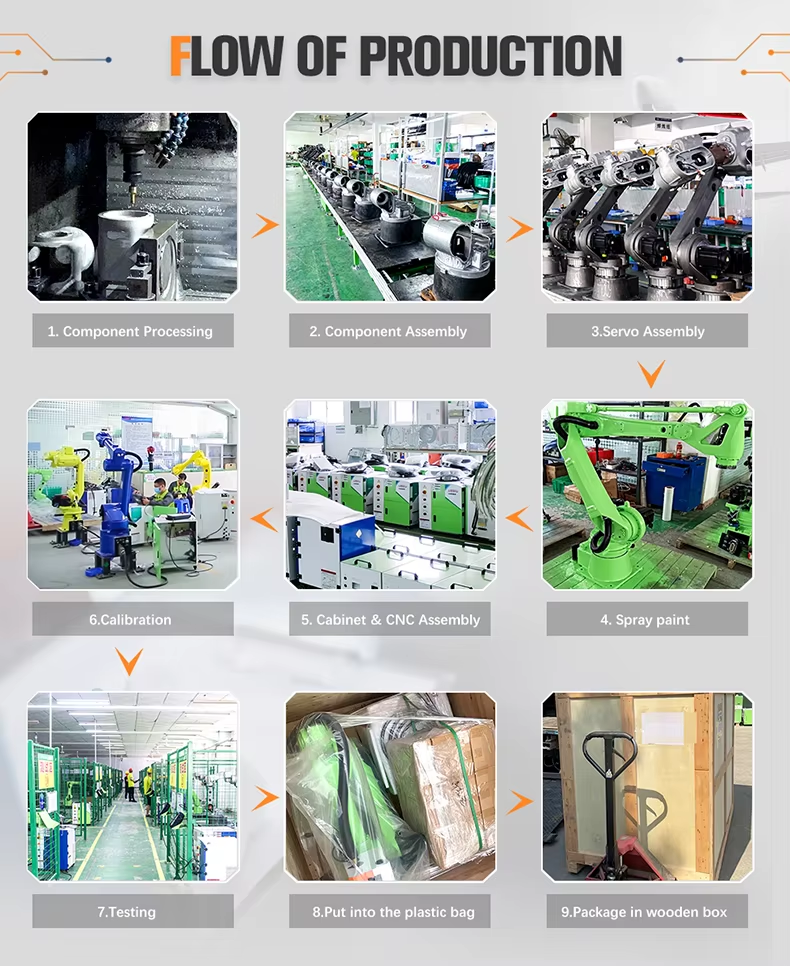

Product Description

The Robotic Arm Control System is a high-performance, modular industrial robot controller designed for flexible automation solutions. It supports up to 12 axes of control, combining advanced motion algorithms with an intuitive interface to enable precise, efficient, and safe operations across various manufacturing environments. With built-in software PLC, multi-mode programming, and intelligent anomaly detection, this controller meets the modern industry’s demand for smart manufacturing, 24/7 reliability, and scalable integration.

Application

| Industry | Application |

| Automotive | Welding, part handling, painting, and assembly lines |

| Electronics | PCB handling, soldering, inspection, and assembly |

| Metal Processing | Cutting, welding, grinding, and polishing |

| Packaging | Sorting, palletizing, boxing, and labeling |

| Home Appliances | Assembly, screwing, gluing, and conveyor handling |

| Medical Equipment | Precision part handling, assembly, and packaging |

Product Features

EASY TO OPERATE

The buttons of the teach pendant are simple and easy to understand, and the teaching programming can be learn and use quickly. If the operation is wrong, the machine automatically stops to avoid the risk of equipment damage.

WORK EFFICIENTLY

Once programmed, it can be used all the time. robot arm supports 24 hours of continuous work with high precision and high speed. Fully automated operation, a robot can complete the workload of more than 2-3 people a day.

LOW COST

One-time investment, long-term benefits. The service life of robot is 80,000 hours, which is equivalent to more than 9 years of 24-hour uninterrupted work. It greatly saves labor costs and personnel management costs, and solves problems such as difficulty in recruiting people.

SAFE AND RELIABLE

robot arm is equipped with photoelectric safety protection measures. When foreign objects enter the work area, it can automatically alarm and suspend work to avoid accidental injuries.

SAVE ENERGY AND SPACE

automation equipment line layout is simple and tidy, small footprint, no noise, light and strong robot arm, low power consumption, energy saving and environmental protection

Product parameters

| Specification | Details |

| No. of Controlled Axes | 6 basic + 6 external (12 total) |

| Storage | 2GB |

| Teaching Pendant | Full keyboard + touch screen, mode select, safety & emergency switches |

| Programming Methods | Online teaching, process programming, teaching by dragging |

| Motion Functions | Point-to-point, linear, circular |

| Command System | Motion, logic, process, computation |

| Control Mode | Position control |

| Operation Modes | Teaching, representation, remote control |

| Interface | Encoder inputs, terminal I/O, Ethernet, serial communication |

| Anomaly Detection | Servo, emergency, anti-collision, coordinate anomalies, arcing |

| Safety System | Emergency-stop linkage, photoelectric safety measures |

| Lifetime | 80,000 hours (over 9 years continuous operation) |

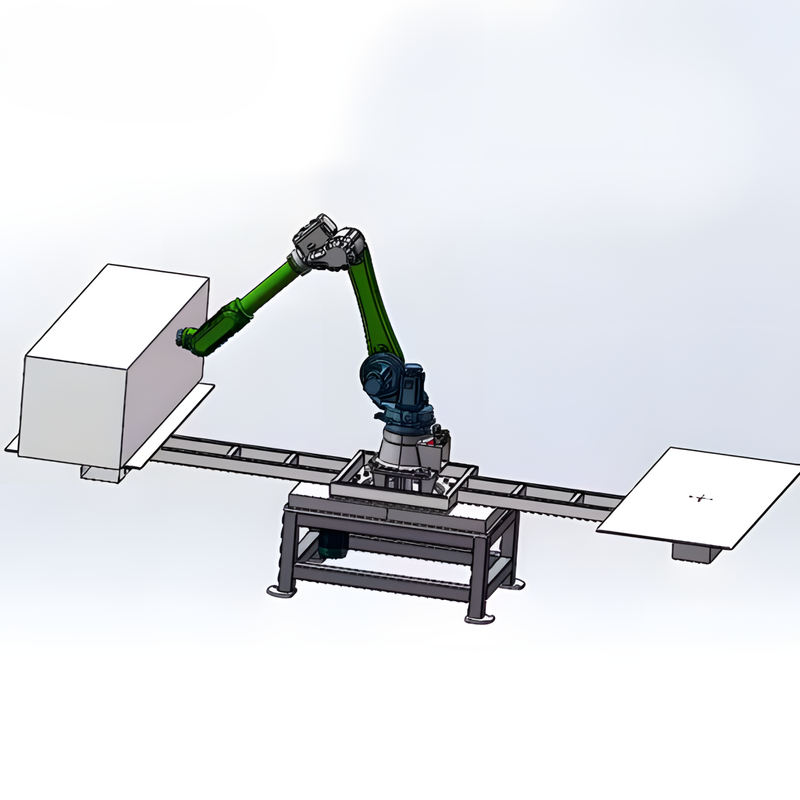

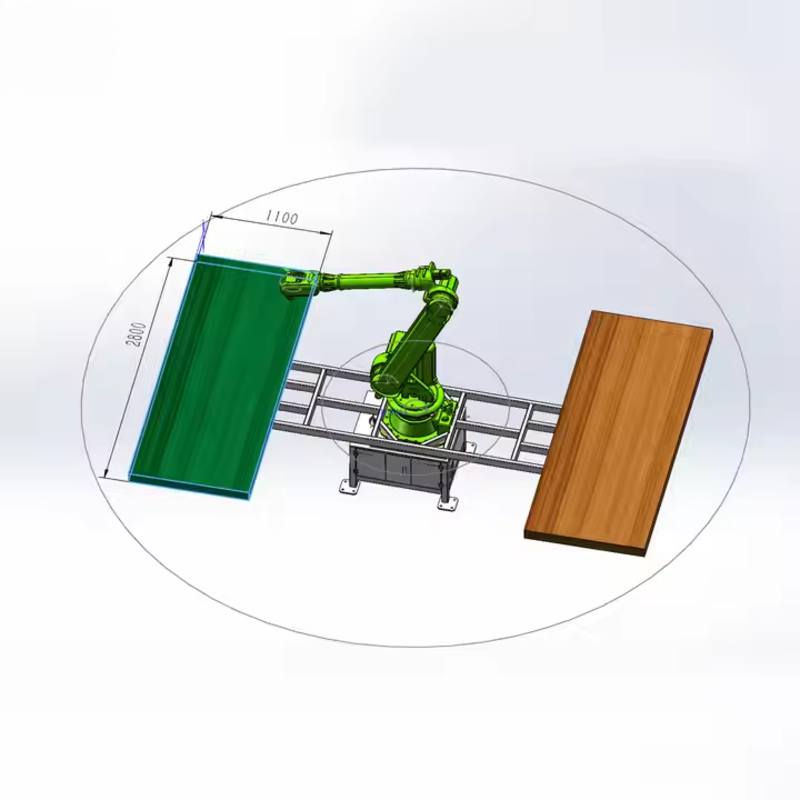

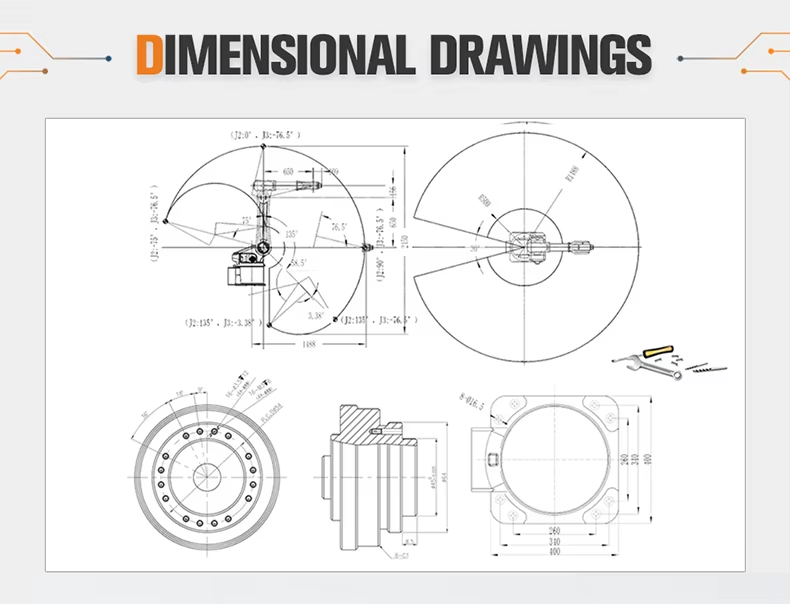

Structure Diagram

Model Parameter

| Payload | 6kg |

| Active radius/Reaching | 1500mm |

| Structure | Articulated |

| Axes | 6 |

| Repeatability (mm) | ±0.05 |

Max motion range & Max Speed

| J1 | ±165° | 148°/sec |

| J2 | +120° / -70° | 148°/sec |

| J3 | +60° / -75° | 148°/sec |

| J4 | ±150° | 222°/sec |

| J5 | +30° / -240° | 222°/sec |

| J6 | ±360° | 360°/sec |

| Weight | ≈150kg |

| Installation method | Ground, Bracket, Ceiling |

| Application | Spraying paint, Powder spraying |

| Ambient temperature | -5℃ ~ 45℃ |

FAQ

Q1: How many axes can the system control?

A: It supports up to 12 axes — 6 robot axes and 6 external (e.g., sliders, rotary tables).

Q2: Can the robot be programmed without coding experience?

A: Yes. It offers drag teaching and process-based programming, making it user-friendly even for beginners.

Q3: What happens if the robot collides with an object?

A: The system includes collision detection. It immediately stops the operation and sends an alert to prevent further damage.

Q4: Is the system compatible with existing automation lines?

A: Yes. The controller features standard Ethernet and serial communication ports for seamless integration with other industrial devices.

Q5: What’s the lifespan of the SZGH robotic system?

A: The average service life is over 80,000 working hours, making it ideal for long-term 24/7 operations.