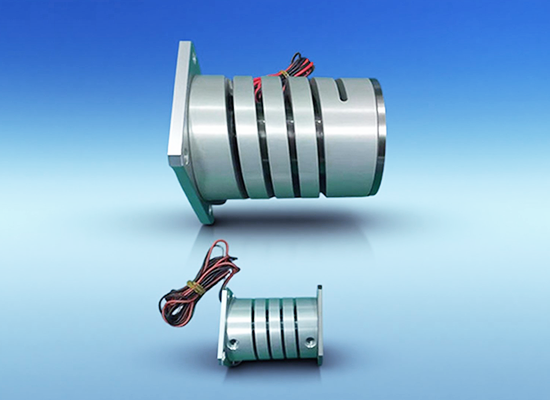

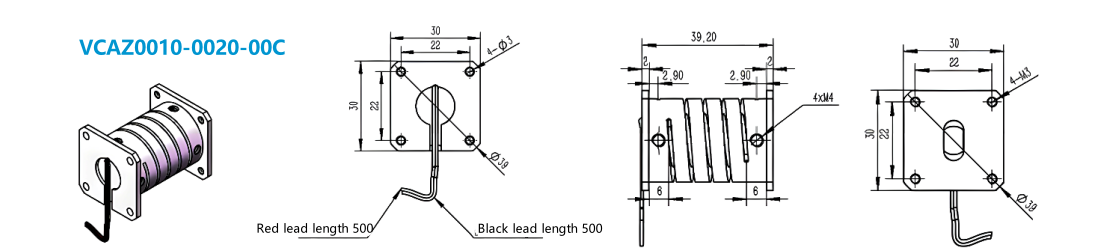

Product Description

The flexible vibration voice coil motor is made of high-strength and stable materials, with fast response, high vibration frequency and good consistency and stability. It adopts special drive control technology and also integrates an adjustable backlight source as the power source of the flexible vibration disk, which helps the various movements of parts and the automatic control of the system, solving the problem of traditional feeding.

Functional Features

◆Break through the traditional feeding problem

◆High-strength and high-stability materials

◆Fast response and high frequency, good consistency and stability

◆Special drive, multiple movements of parts

◆Backlight integration, automatic control

◆Flexible vibration plate power source, workpiece plate movement

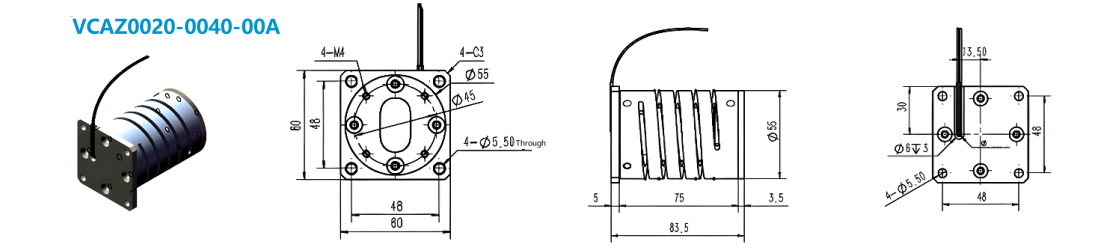

Product parameters

Coil constant | ||||

Tolerance | Symbol | Value | Unit | |

DC resistance | ±10% | R | 10.2 | Ω |

Maximum voltage | Standard value | Vp | 25.9 | V |

Maximum current | Standard value | Ip | 2.6 | A |

Force constant | ±10% | Kf | 8.1 | N/A |

Back electromotive force constant | Standard value | Kb | 8.1 | V/M/sec |

Inductance | ±30% | L | 1.3 | mH |

Motor parameters | ||||

Symbol | Value | Unit | ||

Maximum thrust | Fp | 20.5 | N | |

Continuous thrust | Fc | 8.9 | N | |

Motor constant | Ka | 2.55 | N/√W | |

Electrical time constant | Te | 0.13 | milli-sec | |

Maximum power consumption | Pp | 65.3 | W | |

Total stroke | S | 3.0 | mm | |

Friction | Ff | 1.5 | mN | |

Thermal resistance | θth | 7.3 | ℃/W | |

Maximum allowable coil temperature | Tmax | 150 | ℃ | |

Coil weight | WTc | 110 | g | |

Magnetic weight | WTf | 285 | g | |

Motor weight | WTa | 375 | g | |

Motor length | L | 83.5 | mm | |

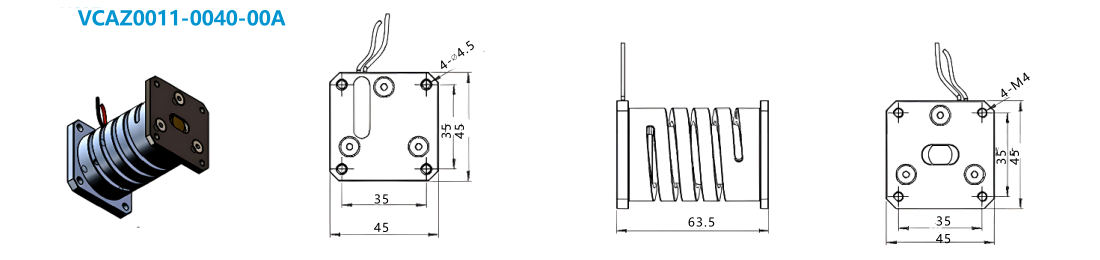

Coil constant | ||||

Tolerance | Symbol | Value | Unit | |

DC resistance | ±10% | R | 15.2 | Ω |

Maximum voltage | Standard value | Vp | 24 | V |

Maximum current | Standard value | Ip | 1.6 | A |

Force constant | ±10% | Kf | 6.5 | N/A |

Back electromotive force constant | Standard value | Kb | 6.5 | V/M/sec |

Inductance | ±30% | L | 2.2 | mH |

Motor parameters | ||||

Symbol | Value | Unit | ||

Maximum thrust | Fp | 10.3 | N | |

Continuous thrust | Fc | 6.4 | N | |

Motor constant | Ka | 1.67 | N/√W | |

Electrical time constant | Te | 0.15 | milli-sec | |

Maximum power consumption | Pp | 38 | W | |

Total stroke | S | ±2.0 | mm | |

Friction | Ff | 1.5 | mm | |

Thermal resistance | θth | 8.5 | ℃/W | |

Maximum allowable coil temperature | Tmax | 150 | ℃ | |

Motor weight | WTa | 270 | g | |

Coil constant | ||||

Tolerance | Symbol | Value | Unit | |

DC resistance | ±10% | R | 9.5 | Ω |

Maximum voltage | Standard value | Vp | 14.8 | V |

Maximum current | Standard value | Ip | 1.6 | A |

Force constant | ±10% | Kf | 2.7 | N/A |

Back electromotive force constant | Standard value | Kb | 2.7 | V/M/sec |

Inductance | ±30% | L | 0.37 | mH |

Motor parameters | ||||

Symbol | Value | Unit | ||

Maximum thrust | Fp | 4.2 | N | |

Continuous thrust | Fc | 2.2 | N | |

Motor constant | Ka | 0.87 | N/√W | |

Electrical time constant | Te | 0.04 | milli-sec | |

Maximum power consumption | Pp | 24 | W | |

Total stroke | S | 1.5 | mm | |

Friction | Ff | 0.8 | mN | |

Thermal resistance | θth | 20 | ℃/W | |

Maximum allowable coil temperature | Tmax | 150 | ℃ | |

Coil weight | WTc | 13 | g | |

Magnetic weight | WTf | 56 | g | |

Motor weight | WTa | 69 | g | |

Application

Flexible vibration voice coil motors are used in electronics, automotive parts, medical devices and other fields. They can realize automated loading of precision parts, conveying of small parts on 3C assembly lines and automated processing of laboratory parts.

Quality Control

The core materials of the common parts of voice coil motors are strictly controlled, the coils are precisely wound, and the magnetic circuit system is calibrated to ensure uniform magnetic field. The assembly follows high-precision alignment standards, passes multiple rounds of environmental and mechanical tests, and has stable dynamic response. Full inspection before leaving the factory ensures reliable quality.

Service

Voice coil motor services run through the entire product life cycle. Detailed technical consultation is provided before sales, and selection and matching are assisted based on application scenarios; real-time follow-up of production and logistics is carried out during sales to ensure efficient and accurate delivery; after sales, rapid response to needs is provided, installation guidance and troubleshooting support are provided, and the quality assurance system is linked to solve problems, ensuring the stable operation of the equipment in all aspects.