Brand-Official Supplier

11 years

Brand-Official Supplier

11 years

Backpack AGV-200kg

Automatic Guided Vehicle TransportationWarehouse Material Handling EquipmentBackpack AGV Robots

- Basic dimension:900*600*300mm

- Maximum load:200

- Maximum speed:0-60

- Turning radius:700

- Communication method:WIFI (2.4G/5G)

- Stopping accuracy:±10

USD: 10000-30000

ablity:Monthly Output500

- Product Description

- Product Params

Product Description

Backpack AGV-200kg

Apply to workshop handling, turnover cache, automation supporting, etc.;

Carrying workpieces and rubber frames to improve transportation efficiency and reduce labor.

Combined with the system and scheduling system, to realize the site production logistics automatic transfer, to achieve intelligent fully automatic transportation

Product Features

1.With 90 degree turn and arc turn

With in-situ 90-degree turn and arc turn function, can also be forward and backward, can be applied to a variety of narrow space environment.

2.Applicable to a variety of scenes

Applicable to a variety of industry application scenarios, a variety of environmental factors, a variety of driving surface, strong adaptability.

3.Movement speed adjustable

Adopt double-wheel differential drive, speed adjustable, speed (0-60m/min).

4. Synchronized autonomous operation of multiple equipment

With multiple AGV synchronized operation, autonomous operation according to the scheduling instructions, set control procedures, no manual intervention in the production process.

5. Fault self-test recovery function

With perfect fault self-test function, and with remote fault diagnosis and recovery function.

6. Equipped with radar detection sensor

Equipped with radar obstacle detection sensors, mechanical anti-collision devices and sound and light alarm systems to ensure safe operation.

Product Parameters

| Product Sequence | Backpack AGV | |

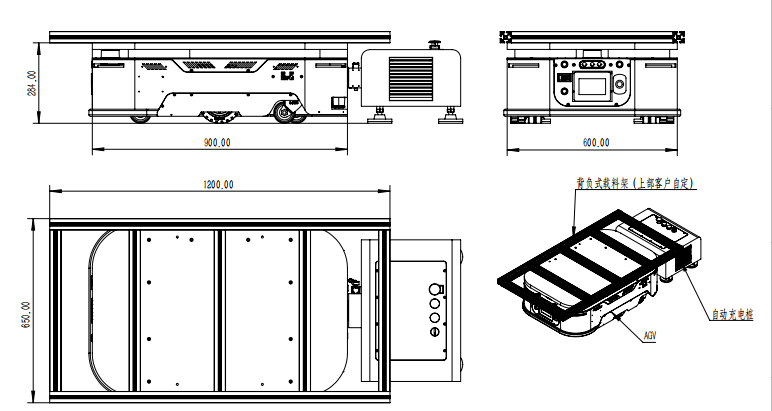

| Basic dimension | 900*600*300mm | |

| Navigation Methods | SLAM laser navigation | SLAM mapping |

| Control method | All-in-one controller | Customization |

| Drive motor | Servo motor | 200*2 |

| Driving method | Two-wheel differential | |

| Load method | Backpacking equipment | |

| Maximum load | 200 | |

| Running direction | Bi-directionality | Forward + Backward + Arc Turn |

| Maximum speed | 0-60 | Straight and level running |

| Turning radius | 700 | |

| Safety protection | Front and rear laser obstacle avoidance | Mechanical collision avoidance + emergency stop |

| Nodal recognition | SLAM | |

| Communication method | WIFI (2.4G/5G) | Optional |

| Stopping accuracy | ±10 |

Application scenario

· Application Scenarios: Production Line Material Handling, Intelligent Warehouse Transportation, etc. · Application industries: electronic factories, warehouse logistics, general workshop and other intelligent transformation |

Supplier Information

Company Name:Shenzhen Uwant Technology Co., Ltd.

Contact Email:uwantech@ttbridge.com

Recommended products

AGV car load 500KG

Automatic handling robot unmanned transport latent traction skip agv car

collect:0

Automatic loading and unloading agv car

Intelligent warehouse automatic loading and unloading agv car 12 storage positions handling turnover cache express sorting scheme

collect:0

Macram wheel lift transporter

Macram wheel lift transport intelligent automatic agv carrier chassis AGV car manufacturer Youwant

collect:0

Loading and unloading forklift AGV-30KG

High-quality AGV robot intelligent warehouse loading and unloading forklift

collect:0