Product Description

Planetary gearbox is a kind of reducer with wide versatility. The inner gear adopts low carbon alloy steel carburizing quenching and grinding or nitriding process. Planetary gearbox has the characteristics of small structure size, large output torque, high speed ratio, high efficiency, safe and reliable performance, etc. The inner gear of the planetary gearbox can be divided into spur gear and helical gear. Customers can choose the right precision reducer according to the needs of the application.

Product parameters

| WADR Series Performance Table | |||||||

| Specification | Unit | Staqe | Ratio | WADR064 | WADR090 | WADR110 | WADR140 |

| Rated output torqueT2N | Nm | 1 | 4 | 48 | 130 | 270 | 560 |

| 5 | 60 | 160 | 330 | 650 | |||

| 7 | 50 | 140 | 300 | 550 | |||

| 10 | 40 | 100 | 230 | 450 | |||

| 14 | 42 | 140 | 300 | 550 | |||

| 20 | 40 | 100 | 230 | 450 | |||

| 2 | 25 | 60 | 160 | 330 | 650 | ||

| 35 | 50 | 140 | 300 | 550 | |||

| 40 | 48 | 130 | 270 | 560 | |||

| 50 | 60 | 160 | 330 | 650 | |||

| 70 | 50 | 140 | 300 | 550 | |||

| 100 | 40 | 100 | 230 | 450 | |||

| 140 | 50 | 140 | 300 | 550 | |||

| 200 | 40 | 100 | 230 | 450 | |||

| Emergency stop torque T2NOT | Nm | 1,2 | 4-200 | Triple rated output torque | |||

| Rated input speed η1N | rpm | 1,2 | 4-200 | 5000 | 4000 | 4000 | 3000 |

| Maximum input speed η1B | rpm | 1,2 | 4-200 | 10000 | 8000 | 8000 | 6000 |

| Precision backlash P1* | arcmin | 1 | 4〜20 | ≤4 | ≤4 | ≤4 | ≤4 |

| 2 | 25-200 | ≤7 | ≤7 | ≤7 | ≤7 | ||

| Standard backlash P2* | arcmin | 1 | 4〜20 | ≤6 | ≤6 | ≤6 | ≤6 |

| 2 | 25-200 | ≤9 | ≤9 | ≤9 | ≤9 | ||

| Economic backlash P3 | arcmin | 1 | 4〜20 | ≤ 8 | ≤8 | ≤8 | ≤8 |

| 2 | 25-200 | ≤12 | ≤12 | ||||

| Torsional rigidity | Nm/arcmin | 1,2 | 4-200 | 13 | 31 | 82 | 151 |

| Maximum bendinq torque M2KB | Nm | 1,2 | 4-200 | 125 | 235 | 430 | 1300 |

| Allowable axial force F2aB | N | 1,2 | 4-200 | 1050 | 2850 | 2990 | 10590 |

| Lifespan | hr | 1,2 | 4-200 | 20000* | |||

| Efficiency | % | 1 | 4〜20 | ≥95% | |||

| 2 | 25-200 | ≥92% | |||||

| Weight | kg | 1 | 4~20 | 2.1 | 5.9 | 10.5 | 21.9 |

| 2 | 25-200 | 1.9 | 4.5 | 9.8 | 20.1 | ||

| Working temperature | °C | 1,2 | 4-200 | (-10° C +90° C ) | |||

| Lubricating | Synthetic lubricating grease | ||||||

| IP Grade | 1,2 | 4-200 | IP65 | ||||

| Installation direction | 1,2 | 4-200 | In any direction | ||||

| Noise level ( η1=3000rpm,off load) | dB(A) | 1,2 | 4-200 | ≤63 | ≤65 | ≤68 | ≤70 |

| (Need confirm wilh our engineer for those precision data with*) | |||||||

Technological Innovation

High efficiency: transmission efficiency is as high as 97% or more

Low noise: exquisite design, precision manufacturing, noise is less than 63dB(A)

High input speed: maximum input speed can reach 10000 rpm

Low backlash: single section less than 2 arc minutes, double section less than 3 arc minutes

High reduction ratio: modular design, planetary gearboxes can be connected to each other with high speed ratio

Product Views

The meshing of the spiral bevel gear is subjected to the best motion error analysis and strict process control to ensure high-precision operating backlash.

The input end is connected to the motor shaft using a double-sided clamping method to obtain the maximum clamping force and zero backlash power transmission.

The spiral bevel gear design allows high output torque, which is more than 30% higher than the straight bevel gear.

The high allowable input speed is more than 8 times higher than the straight bevel gear input.

The meshing tooth print of the spiral bevel gear is optimally optimized, the contact tooth surface load is uniform, and the operating life is long.

The planetary arm and output shaft adopt an integrated structural design to ensure maximum torsional rigidity.

The planetary gear adopts a full needle roller design to increase the contact area to improve the structural rigidity and output torque.

The gear is made of low-carbon steel surface carburized and quenched to HRC62 to obtain the best wear resistance and impact toughness.

The tooth shape uses imported software to assist in design to obtain the best tooth shape to reduce noise.

The meshing tooth print of the spiral bevel gear is optimally optimized, the contact tooth surface load is uniform, and the operating life is long.

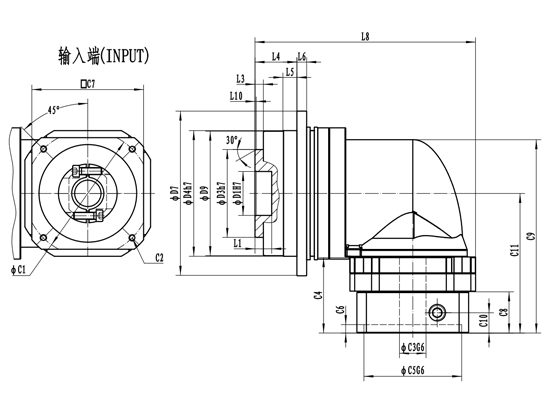

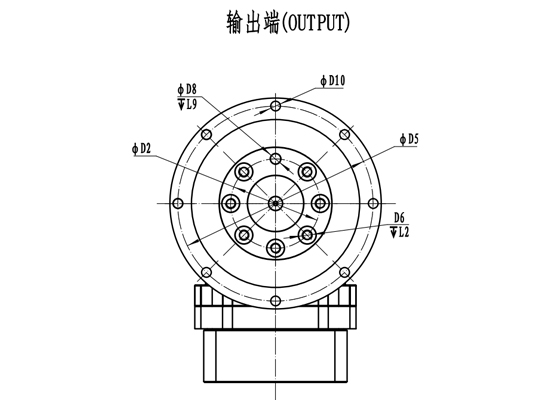

Size & Interface

Application Cases

WANSHSIN products are widely used in automated production lines, robots, engineering machinery, warehousing and logistics, garages, construction elevators, ceramics, animal husbandry and other industries.

Company Introduction

Wanshsin Seikou (Hunan) Co.,Ltd.

WANSHSIN SEIKOU was founded in Dongguan, Guangdong in 2009 and moved its headquarters to Changsha, Hunan in 2014. It currently has the Hunan Enterprise Technology Center and Changsha Technology Innovation Center platforms, and has successively established three R&D centers in Japan, Shenzhen, and Hunan headquarters to lead the high-quality development of the industry with innovation.

WANSHSIN SEIKOU is a professional reducer, reduction motor, controller manufacturer and intelligent automation full-set solution provider integrating R&D, production, sales, and service. Products cover: machine (reducer), electricity (motor), controller (servo drive, inverter), and has become one of the companies with the most complete product line in the field of reducers. Products are widely used in automated production lines, robots, engineering machinery, warehousing and logistics, garages, construction elevators, ceramics, animal husbandry and other industries.

Cooperative partner

Service

Independent production, high quality and high efficiency

It has a modern production workshop of more than 60,000 square meters, imported various high-end processing centers, more than 200 CNC machine tools, standard laboratory testing center, and more than 100 various testing equipment.

Elite team brings together elite engineers

The core technical team experts have more than 20 years of experience in the power transmission industry. The senior R&D team consists of more than 10 mechanical doctors and masters. The production and manufacturing are strictly controlled by senior technicians with more than 15 years of experience.

Technology precipitation, multiple product patents

The company's production has passed ISO9001 quality system certification and ISO14001 environmental system certification. The products have passed 3C, CE and other professional certifications, and have more than 90 patents.