Product Description

Our Metal Stamping Service is engineered to deliver precision-formed metal components tailored to meet the most demanding specifications. Using state-of-the-art stamping presses and dies, we transform metal sheets into complex, high-tolerance parts ideal for high-performance and mission-critical systems.

Materials Supported: Stainless steel, aluminum, copper, titanium, specialty alloys

Capabilities: Progressive die stamping, deep drawing, multi-slide stamping, fine blanking

Tolerances: As tight as ±0.001 inches (depending on material and part geometry)

Production Volume: From prototyping to high-volume production runs

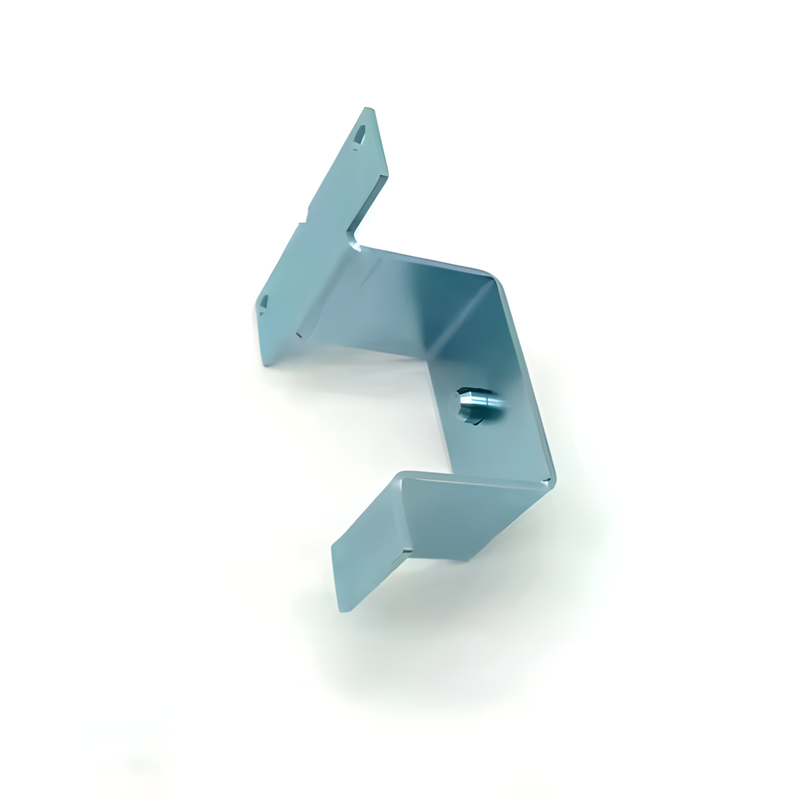

Flat Spring Shrapnel (Cosmic-FS) |

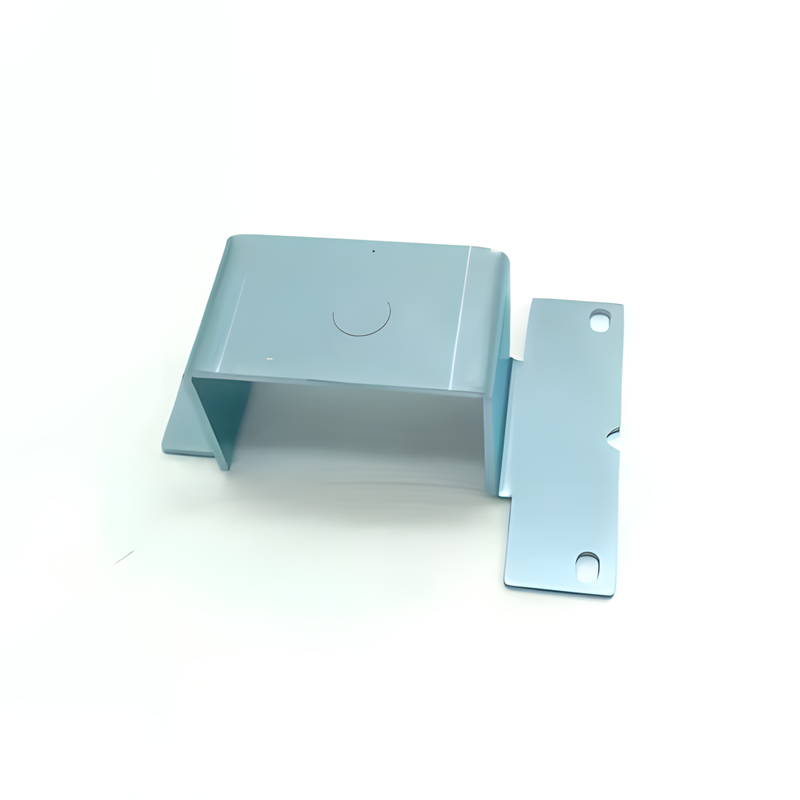

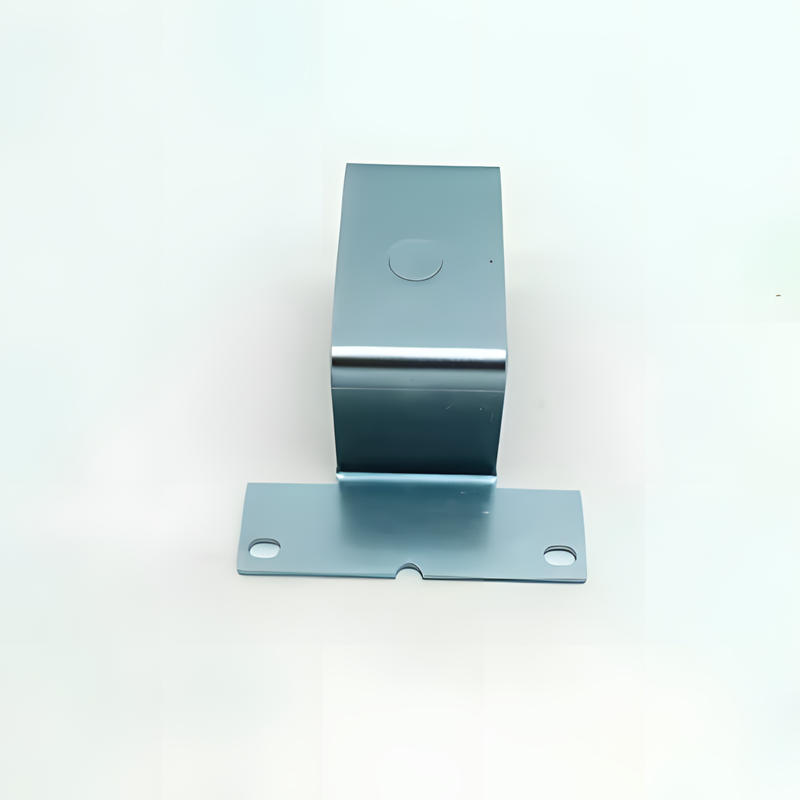

Dome Shrapnel (Cosmic-DS) |

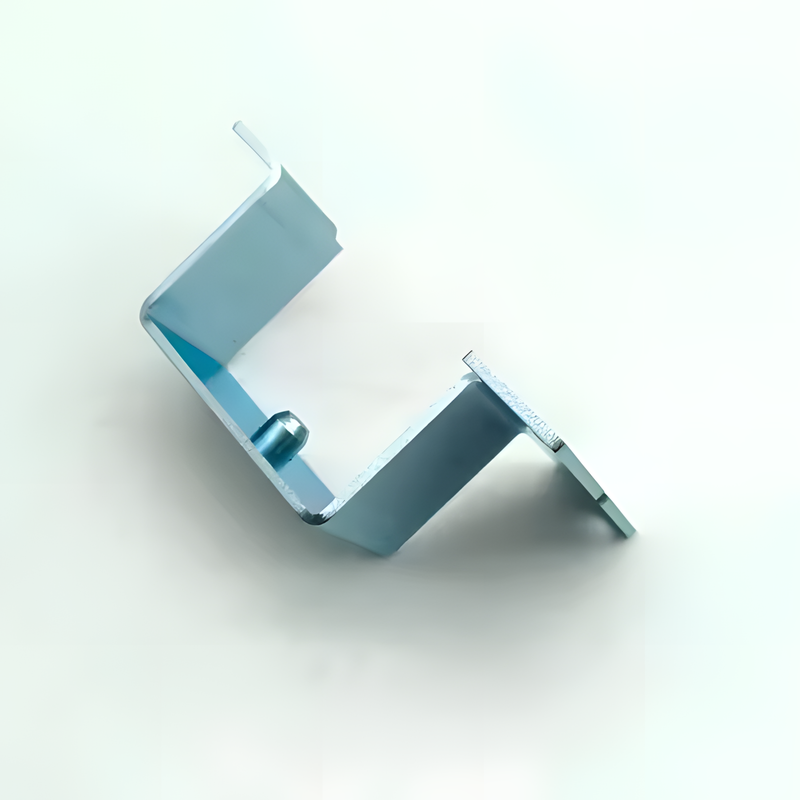

Contact Shrapnel (Cosmic-CS) |

Functional Features

Precision Engineering: Each component is stamped to exacting dimensions for consistent fit and function. |

High Strength-to-Weight Ratio: Ideal for advanced aerospace or tech applications where weight and durability are critical. |

Complex Geometry Support: Capable of producing intricate shapes that reduce the need for secondary machining. |

Surface Finishing Options: Includes anodizing, plating, passivation, and powder coating for added protection and performance. |

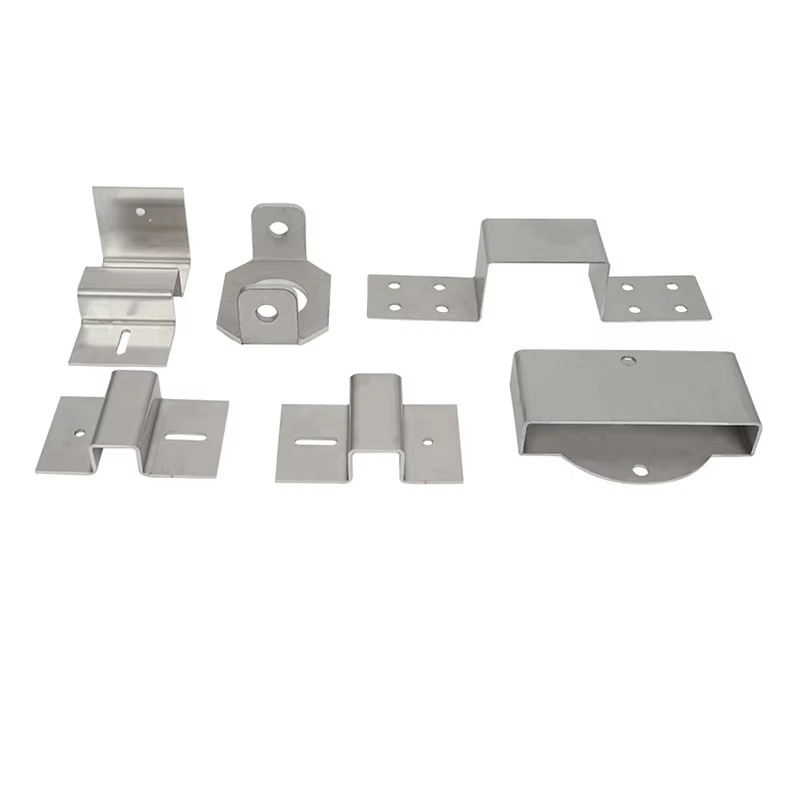

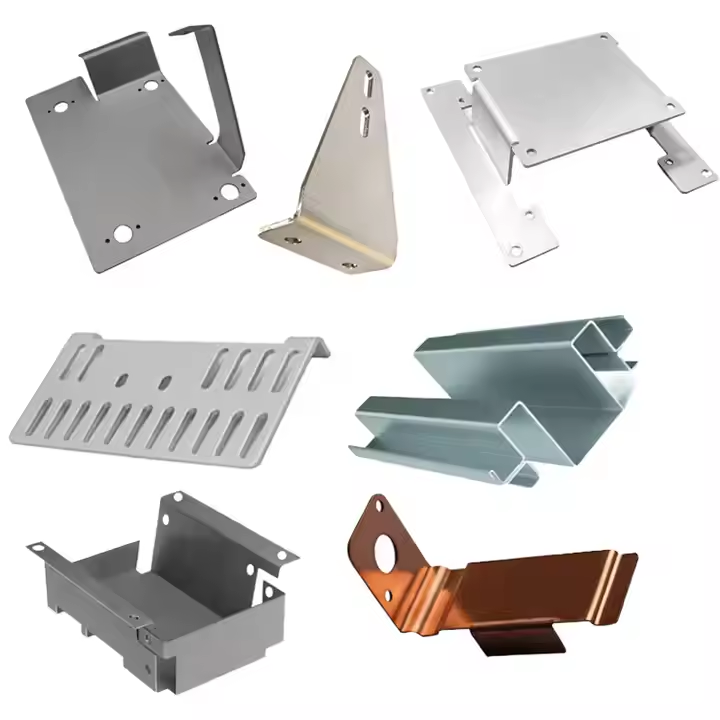

Product Display

Application

Non-standard stamped spring components Application fields: Automation equipment / Warehousing and logistics / New energy equipment / Electronic and electrical appliances / Automobile manufacturing) Communication equipment / Medical equipment / Household appliances / Machinery equipment / Furniture industry / Intelligent passage systems, etc.

Product parameters

| Parameter | Flat Spring (Cosmic-FS) | Dome (Cosmic-DS) | Contact (Cosmic-CS) |

| Material | Beryllium Copper / Bronze | Stainless Steel (301/304) | Copper Alloy / Tin Steel |

| Thickness | 0.05 – 0.3 mm | 0.05 – 0.15 mm | 0.1 – 0.5 mm |

| Width / Diameter | Custom (3 – 30 mm typical) | 4 – 15 mm (typical dome) | Custom (2 – 25 mm typical) |

| Hardness | HRC 35 – 45 | HRC 40 – 50 | HRC 30 – 42 |

| Surface Finish | Nickel / Tin / Gold Plated | Bright / Matte / Plated | Nickel / Gold / Tin Plated |

| Tensile Strength | ≥ 600 MPa | ≥ 800 MPa | ≥ 400 MPa |

| Operating Temperature | -40°C to +150°C | -20°C to +125°C | -40°C to +200°C |

| Conductivity | High | Medium | High |

| Tolerances | ±0.01 – ±0.05 mm | ±0.02 mm | ±0.03 mm |

Custom Process

QUESTION

NEGOTIATION

CONFIRM

PRODUCTION

Quality Control

1. Incoming Material Inspection

Material Certification Review: Verify composition (e.g., Cu, Sn, Be content) per supplier CoA

Hardness Testing: Using Rockwell or Vickers scale

Surface Quality: Check for oxidation, scratches, or surface defects

Thickness & Flatness Check: Micrometer/gauge verification

2. In-Process Inspection

Stamping Accuracy Check: Ensure tolerance within ±0.01–0.05 mm

Burr & Edge Inspection: Optical or manual visual check to ensure safe, smooth edges

Dimensional Control: 100% sampling for high-tolerance parts using calipers or automated vision systems

Tool Wear Monitoring: Periodic check of die condition and wear marks

3. Surface Treatment Inspection

Plating Thickness Test: XRF (X-ray fluorescence) test for gold, tin, or nickel coatings

Adhesion Test: Tape or bending test to verify coating adherence

Corrosion Resistance Test: Salt spray test (ASTM B117 standard)

4. Final Product Inspection

Functional Testing: Conductivity, spring-back force, and insertion/removal force

Tactile Feedback Test: (For dome-type) Actuation force, rebound speed

Full Visual Inspection: 100% visual check for cracks, deformation, or discoloration

Packaging QC: Quantity, lot number, label accuracy, and ESD-safe packaging verification

5. Documentation & Compliance

Inspection Records: Maintained per ISO 9001:2015 or IATF 16949

RoHS / REACH Compliance Reports: Provided upon request

PPAP / FAI Reports: Available for OEM/automotive projects

SPC Charts: For critical dimension tracking

Quality Assurance

We adhere to rigorous quality control protocols to ensure the highest product reliability and compliance with industry standards.

Certifications: ISO 9001, AS9100, RoHS compliant

Inspection Processes: First article inspection (FAI), SPC, CMM dimensional analysis, and in-line quality checks

Traceability: Full material and process traceability with detailed documentation

Testing Options: Tensile strength, fatigue, corrosion resistance, and stress testing upon request

FAQ

1. What materials are available for your metal stamping shrapnel?

We offer a wide range of materials including stainless steel (301, 304), beryllium copper, phosphor bronze, and custom copper alloys. Surface treatments such as nickel, gold, or tin plating are also available.

2. Can I request a custom design or shape?

Yes. We provide custom stamping services based on your drawings or technical requirements. We support prototyping, tooling, and full-scale production.

3. What is the typical tolerance you can achieve?

Our precision stamping process allows for tolerances as tight as ±0.01 mm, depending on the part geometry and material.

4. What are the typical applications for these shrapnel components?

Common uses include:

Battery contacts

Switches and keypads

PCB terminals

Automotive sensors

Consumer electronics

Smart devices

5. Are your products RoHS and REACH compliant?

Yes. All materials and finishes used comply with RoHS and REACH environmental standards. Certifications can be provided upon request.