Product Description

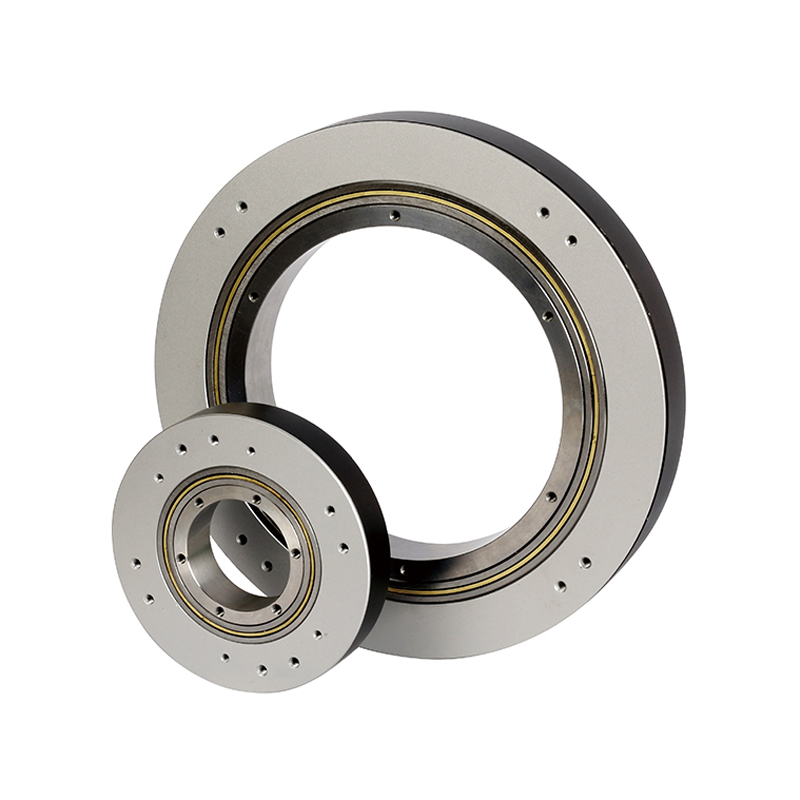

The outer diameter of K70C is 70mm, which is widely used in economical CNC machine tools.

There are various output forms for customers to choose from, and the number of pulses can reach up to 6000 pulses, which can be customized according to customer requirements.

The imported optoelectronic devices have high reliability, long life, strong anti-interference ability and wide operating temperature range.

Product parameters

Mechanical parameters

| Maximum speed (r/min) | Starting torque (25℃) (N.M) | Maximum axial load (N) | Moment of inertia (kgm²) | Weight(kg) | |

|---|---|---|---|---|---|

| Radial | Axial | ||||

| 6000 | 2*10-³ | 40 | 30 | 4 *10-6 | ≤0.315 |

Electrical parameters

| Output form | Power supply voltage DC(V) | Current consumption (mA) | Output voltage(V) | Rise time (ns) | Fall time (ns) | Response frequency (kHz) | |

|---|---|---|---|---|---|---|---|

| VH | VL | ||||||

| E(voltage output) | 5±0.25 | ≤80 | >3.5 | ≤0.7 | ≤500 | ≤100 | 0-300 |

| 8-26 | ≤120 | >VCC-2.5 | ≤0.7 | ≤500 | ≤100 | 0-300 | |

| 10-30 | |||||||

| 12 | |||||||

| F(Complementary output) | 5±0.25 | ≤80 | >3.5 | ≤0.7 | ≤500 | ≤100 | 0-300 |

| 8-26 | ≤120 | >VCC-2.5 | ≤0.7 | ≤500 | ≤100 | 0-300 | |

| 10-30 | |||||||

| 12 | |||||||

| C (collector open circuit output) | 5±0.25 | ≤60 | >VCC-2.5 | ≤0.7 | ≤500 | ≤100 | 0-300 |

| 8-26 | |||||||

| 10-30 | |||||||

| 12 | |||||||

| L (Long line drive output) | 5±0.25 | ≤100 | >3.5 | ≤0.7 | ≤200 | ≤200 | 0-300 |

| A (wide voltage long line drive output) | 8-26 | ≤60 | >VCC-2.5 | ≤0.7 | ≤500 | ≤100 | 0-300 |

Wiring Instructions

| Cable wire color | Red | Black | Green | Brown | White | Grey | Yellow | Orange | Shield |

|---|---|---|---|---|---|---|---|---|---|

| E(voltage output) | Vcc | 0V | A | B | Z | G | |||

| F(Complementary output) | Vcc | 0V | A | B | Z | G | |||

| C (open circuit output) | Vcc | 0V | A | B | Z | G | |||

| L, A (drive output) | Vcc | 0V | A | A/ | B | B/ | Z | Z/ | G |

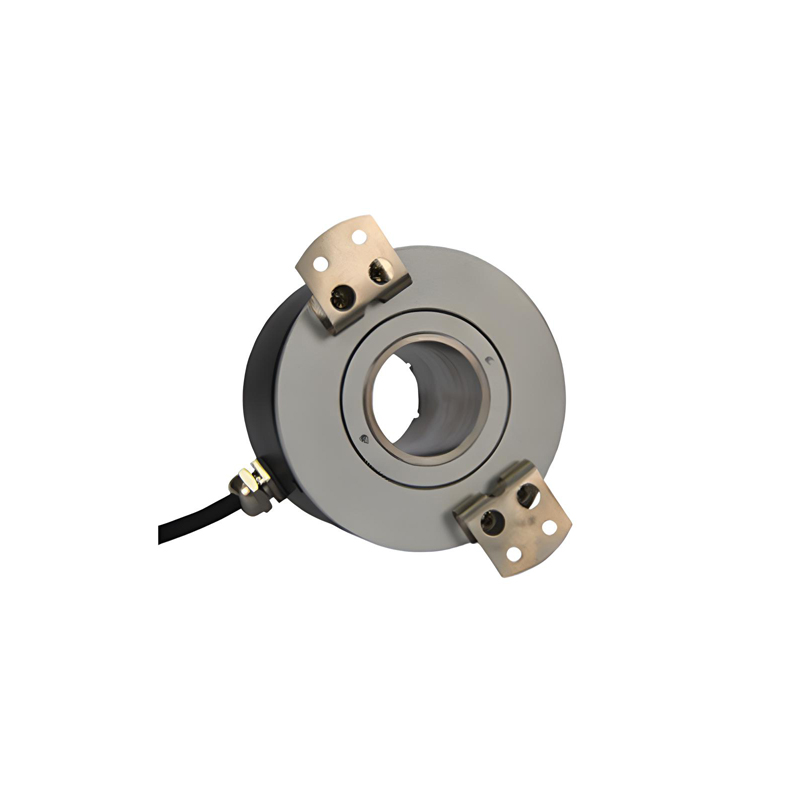

Product Display

- Rugged design: It has a solid mechanical structure that can withstand a certain degree of external impact, vibration and wear, ensuring stable operation in harsh working environments, and is suitable for various industrial scenarios.

- Compact structure: The overall design is compact and does not take up too much space, making it easy to install and layout in the limited space inside the equipment, and has good adaptability to application scenarios with limited space.

- High-precision measurement: As an incremental encoder, it can accurately measure the rotation angle and speed change of the shaft, provide accurate position and speed feedback signals, and meet the requirements of high-precision control. Its high resolution can detect tiny angle changes, providing strong support for the precise control of the system.

- Signal stability and reliability: The output signal is stable and has strong anti-interference ability. It can accurately transmit signals in complex electromagnetic environments to ensure the normal operation of the system. Whether in industrial sites with strong electromagnetic field interference or in automated control systems with high requirements for signal stability, it can maintain good performance.

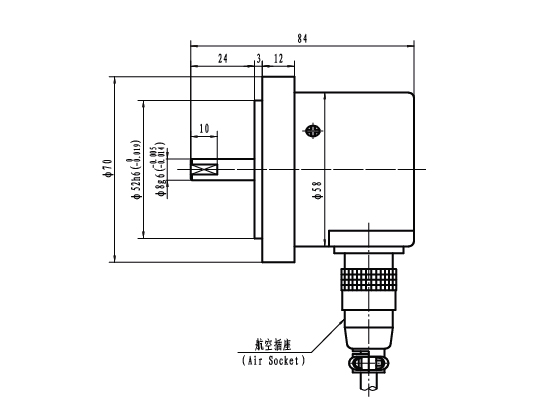

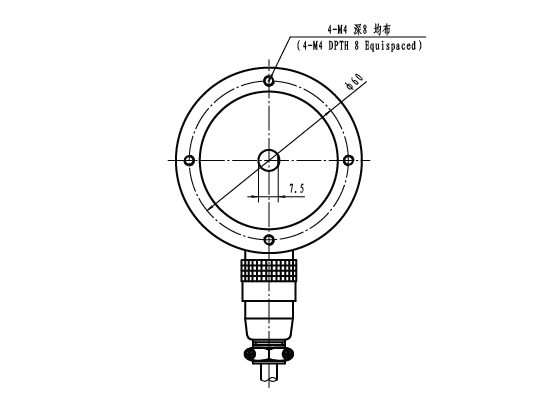

Size & Interface

Application Cases

In the grand scene of modern industrial production, incremental motor encoders are widely used. For example, in the field of CNC machine tools, it is installed on the motor shaft to provide pulse signals for the precise movement of the tool and the precise positioning of the workbench, ensuring the processing accuracy of complex parts at the micron level; in the automated logistics and transportation system, the incremental motor encoder located at the conveyor belt motor can accurately control the speed and start and stop positions, so that the package can flow accurately in the storage, sorting and transportation links; when industrial robots assemble automotive parts, the encoder installed on the joint motor shaft provides real-time feedback information, accurately directs the movement of the robot arm, achieves millimeter-level assembly accuracy, and ensures production quality and efficiency.

Service

The road to success starts with service; quality service starts with me! The products sold are from the original factory and are guaranteed to be original. Honesty is the basis, and our words are our bond. Let us work together to create a win-win situation.