Product Description

Super shape adaptable grabbing:

It can adapt to objects of different shapes such as cylinders, polyhedrons, and spheres, showing a high degree of versatility. This means that in various complex working environments, it can easily handle items of different shapes and improve work efficiency.

This adaptive grasping ability may be due to its advanced sensor technology and sophisticated mechanical structure design. The sensor senses the shape and size of the object, and then the dexterous hand can automatically adjust the grasping posture and strength to ensure stable and accurate grasping of the object.

Product parameters

| degrees of freedom | 7 |

| clamping force | 5-20N |

| self-respect | 0.98kg |

| *Maximum recommended load | 5kg |

| Working voltage | DC24V±10% |

| Maximum current | 3A |

| Power | 60W |

| Open/close time | No more than 1s |

| Communication protocol | Modbus RTU(RS485) |

| Drive mode | Servo motor drive |

| Crawl method | Pinch, grip, wrap grasp |

| Finger structure | Three fingers |

Technological Innovation

It has served dozens of benchmark companies in the medical automation, lithium battery, 3C, semiconductor, food and other industries. In particular, the gripping and rotating integrated electric gripper developed for the test tube opening, code scanning and other processes in the medical industry has provided a perfect solution for the medical industry. made contact contributions.

Product Display

The movement of industrial-grade dexterous hands is achieved through a complex control system. It receives instructions from a host computer (such as the controller of an industrial robot), which include information such as the shape, position, and grasping method of the target object. According to these instructions, the control system accurately drives the movement of each joint through a motor or other drive method. For example, when it is necessary to grasp a mechanical part with an irregular shape, the control system will calculate the angle and speed of each finger joint according to a pre-programmed algorithm, so that the fingers can fit the shape of the part closely for grasping.

Its internal sensors constantly sense the surrounding environment and its own state. When the finger touches the object, the tactile sensor will feedback information such as the size and direction of the contact force to the control system. The control system adjusts the grasping force of the finger in real time based on this feedback information. If the contact force is too small, the object may not be grasped and fall; if the contact force is too large, the object may be damaged.

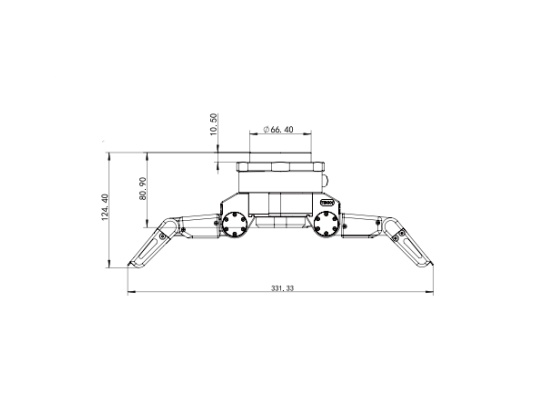

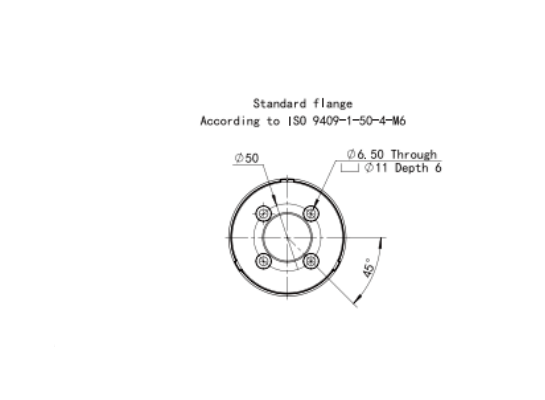

Size & Interface

Application Cases

Industrial-grade dexterous hands have given rise to many huge application potentials in the industry

In the logistics industry, industrial-grade dexterous hands enable efficient cargo sorting and handling. It can quickly and accurately grab packages of different shapes and sizes, improving the efficiency and accuracy of logistics operations. Compared with traditional manual operations, dexterous hands have higher speed and accuracy, which can reduce labor costs and error rates. In addition, dexterous hands can also work in harsh environments, such as high temperature, low temperature, humidity, etc., ensuring the continuity of logistics operations.