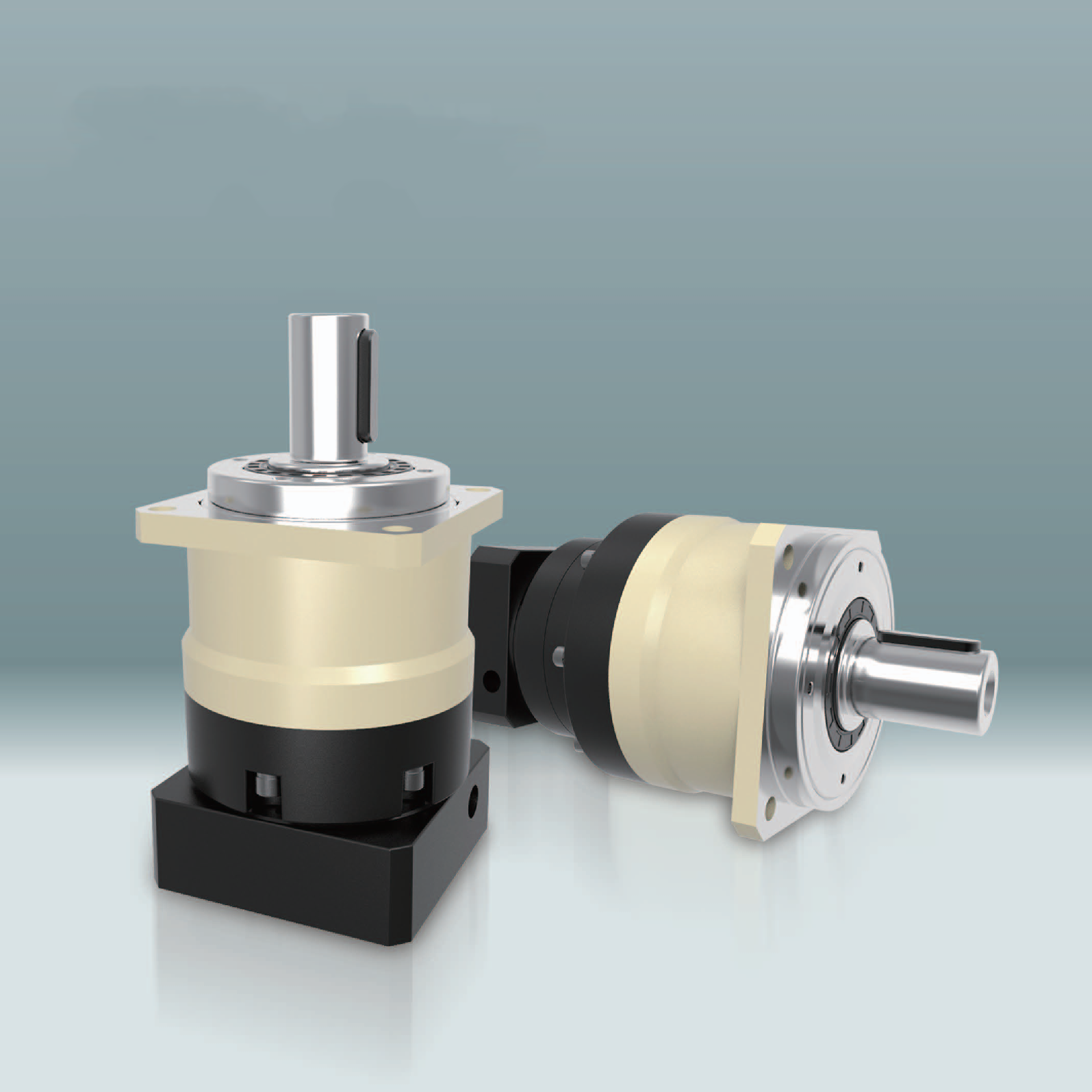

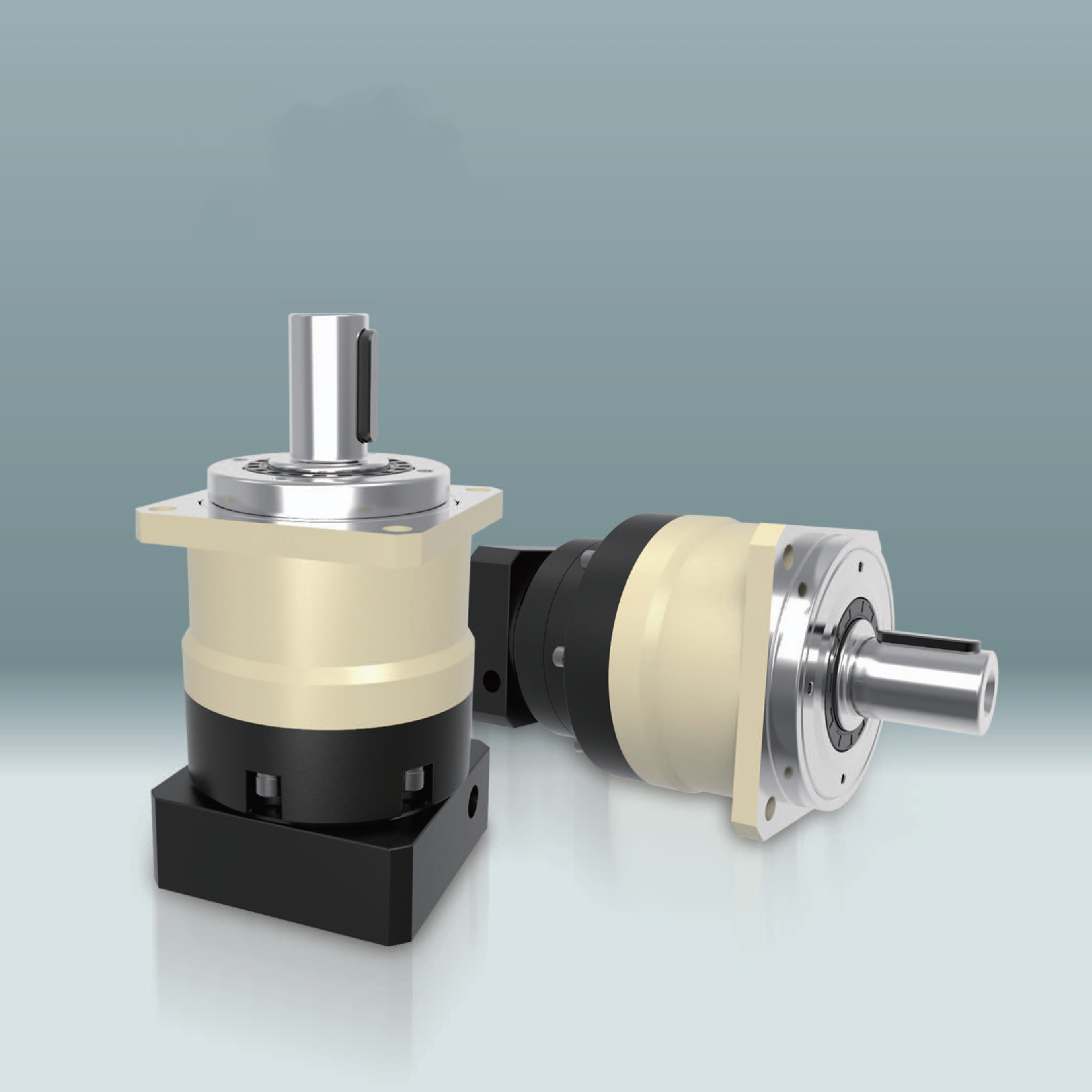

Product Description

In the field of industrial automation and mechanical transmission, precision planetary reducers are like a shining pearl. With its unique advantages and excellent performance, they provide accurate and efficient solutions for many complex transmission systems. It adopts a planetary gear structure, with multiple planetary gears evenly distributed around the sun gear and meshing at the same time. This unique design allows the error to be evenly dispersed between the gears during the transmission process, thereby greatly improving the transmission accuracy. Whether it is a robot joint that requires precise angle control or a robot arm on an automated production line that requires extremely high position accuracy, precision planetary reducers can ensure the precise execution of each action, and the error can be controlled within a very small range, laying a solid foundation for the stable operation of the entire system.

Product parameters

| Specifications | Level | Reduction ratio | MYB042 | MYB090 | MYB180 | |

| Rated output torque | Nm | 1 | 3 | 20 | 130 | 588 |

| 4 | 19 | 140 | 1.05 | |||

| 5 | 22 | 160 | 1,200 | |||

| 6 | 20 | 150 | ||||

| 7 | 19 | 140 | 1,100 | |||

| 8 | 17 | 120 | 1,000 | |||

| 10 | 14 | 100 | 520 | |||

| 2 | 12 | 20 | 130 | |||

| 15 | 20 | 130 | 588 | |||

| 20 | 19 | 140 | 1,050 | |||

| 25 | 22 | 160 | 1,200 | |||

| 30 | 22 | 130 | 1,200 | |||

| 35 | 22 | 160 | 1,200 | |||

| 40 | 22 | 140 | 1,200 | |||

| 50 | 22 | 160 | 1,200 | |||

| 60 | 20 | 150 | ||||

| 70 | 19 | 140 | 1,100 | |||

| 80 | 17 | 120 | 1 | |||

| 100 | 14 | 100 | 520 | |||

| Maximum output torque | Nm | 1,2 | 3~100 | 3 times rated output torque | ||

| Rated input speed | rpm | 1,2 | 3~100 | 5 | 4,000 | 3 |

| Maximum input speed | rpm | 1,2 | 3~100 | 10 | 8 | 6 |

| Backlash | arcmin | 1 | 3~10 | ≤5 | ≤5 | ≤5 |

| 2 | 12~100 | ≤7 | ≤7 | ≤7 | ||

| Torsional rigidity | Nm/arcmin | 1,2 | 3~100 | 3 | 14 | 145 |

| Allowable radial force | N | 1,2 | 3~100 | 780 | 3,250 | 14,500 |

| Allowable axial force | N | 1,2 | 3~100 | 350 | 1,300 | 6.2 |

| Allowable axial force | N | 1,2 | 3~100 | 390 | 1.625 | 7,250 |

| Service life | hr | 1,2 | 3~100 | 20,000* | ||

| Efficiency | % | 1 | 3~10 | ≥97% | ||

| 2 | 12~100 | ≥94% | ||||

| Weight | kg | 1 | 3~10 | 0.5 | 3.7 | 29 |

| 2 | 12~100 | 0.8 | 4.1 | 33 | ||

| Operating temperature | ℃ | 1,2 | 3~100 | -10℃~+90℃ | ||

| Lubrication | 1,2 | 3~100 | Synthetic grease | |||

| Protection level | 1,2 | 3~100 | IP65 | |||

| Installation direction | 1,2 | 3~100 | Any direction | |||

| Noise value (n₁=3000rpm) | dB | 1,2 | 3~100 | ≤56 | ≤60 | ≤67 |

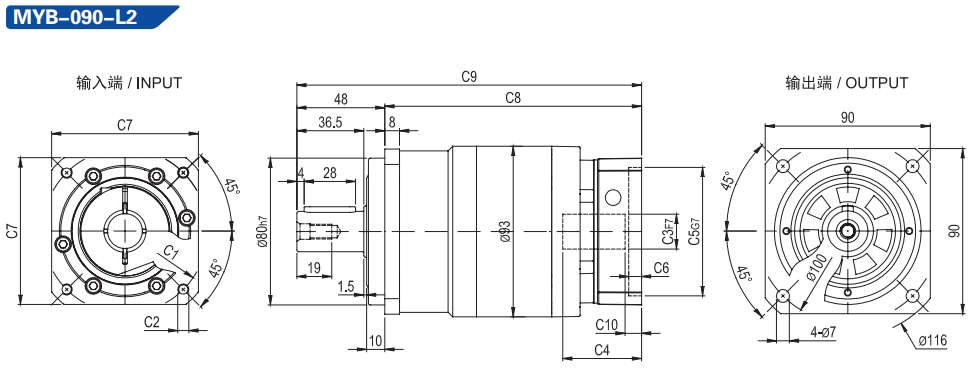

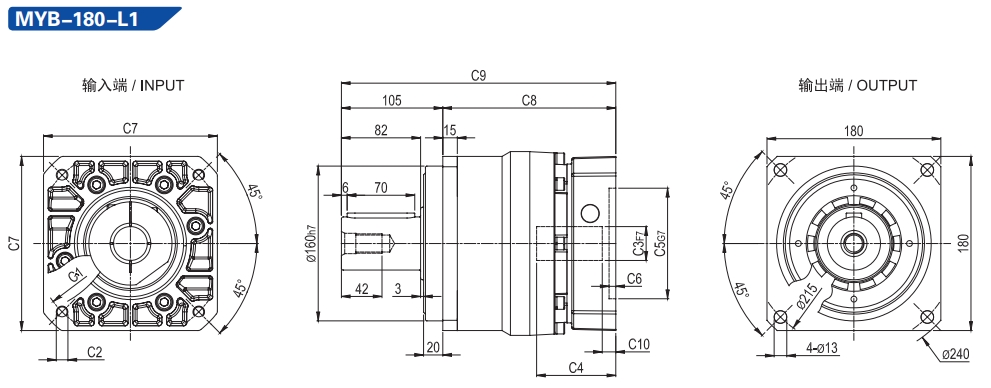

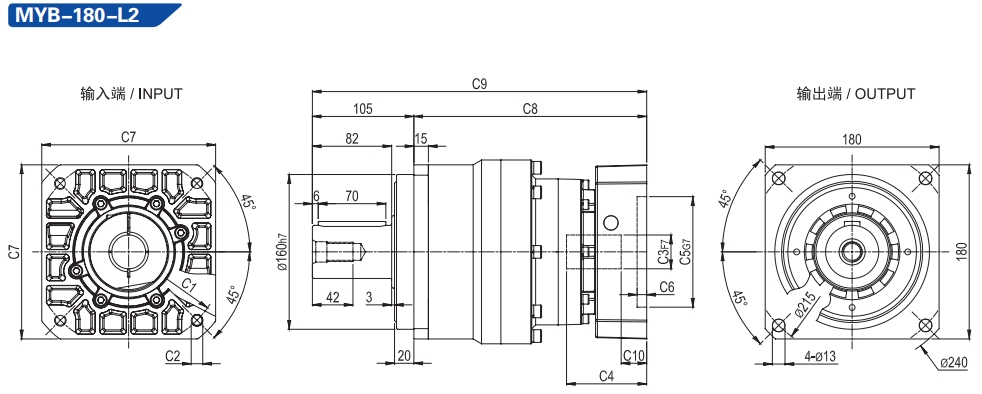

Output shaft diameter

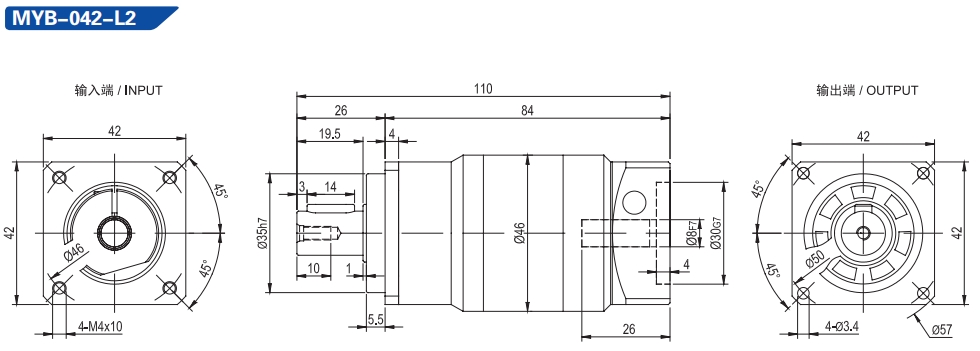

| Dimension | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 |

| MYB-090-L1 | ∅90 | 4-M5x15,4-M6x15 | ∅19 | 43 | ∅70 | 7 | 80 | 99 | 147 | 9 |

| ∅100 | 4-M6x15 | ∅16,∅19 | 43 | ∅80 | 7 | 86 | 99 | 147 | 9 | |

| ∅115 | 4-M8x20 | ∅19,∅22,∅24 | 56.5 | ∅95 | 10 | 100 | 115.5 | 163.5 | 17.5 | |

| ∅145 | 4-M8x20 | ∅19,∅22,∅24 | 60 | ∅110 | 8 | 130 | 119 | 167 | 21 | |

| MYB-090-L2 | ∅90 | 4-M5x15,4-M6x15 | ∅19 | 43 | ∅70 | 7 | 80 | 140 | 188 | 9 |

| ∅100 | 4-M6x15 | ∅16,∅19 | 43 | ∅80 | 7 | 86 | 140 | 188 | 9 | |

| ∅115 | 4-M8x20 | ∅19,∅22,∅24 | 56.5 | ∅95 | 10 | 100 | 156.5 | 204.5 | 17.5 | |

| ∅145 | 4-M8x20 | ∅19,∅22,∅24 | 60 | ∅110 | 8 | 130 | 160 | 208 | 21 | |

| Dimension | C1 | C2 | C3 | C4 | C5 | C6 | C7 | 0 | C9 | C10 |

| MYB-180-L1 | ∅200 | 4-M12x30 | ∅35 | 82 | ∅114.3 | 7 | 180 | 179 | 284 | 14 |

| ∅235 | 4-M12x30 | ∅42 | 120 | ∅200 | 10 | 220 | 217 | 322 | 44 | |

| MYB-180-L2 | ∅145 | 4-M8x20 | ∅22,∅24 | 72 | ∅110 | 10 | 130 | 230 | 335 | 20.5 |

| ∅200 | 4-M12x30 | ∅35 | 83 | ∅114.3 | 10 | 180 | 241 | 346 | 26.5 |

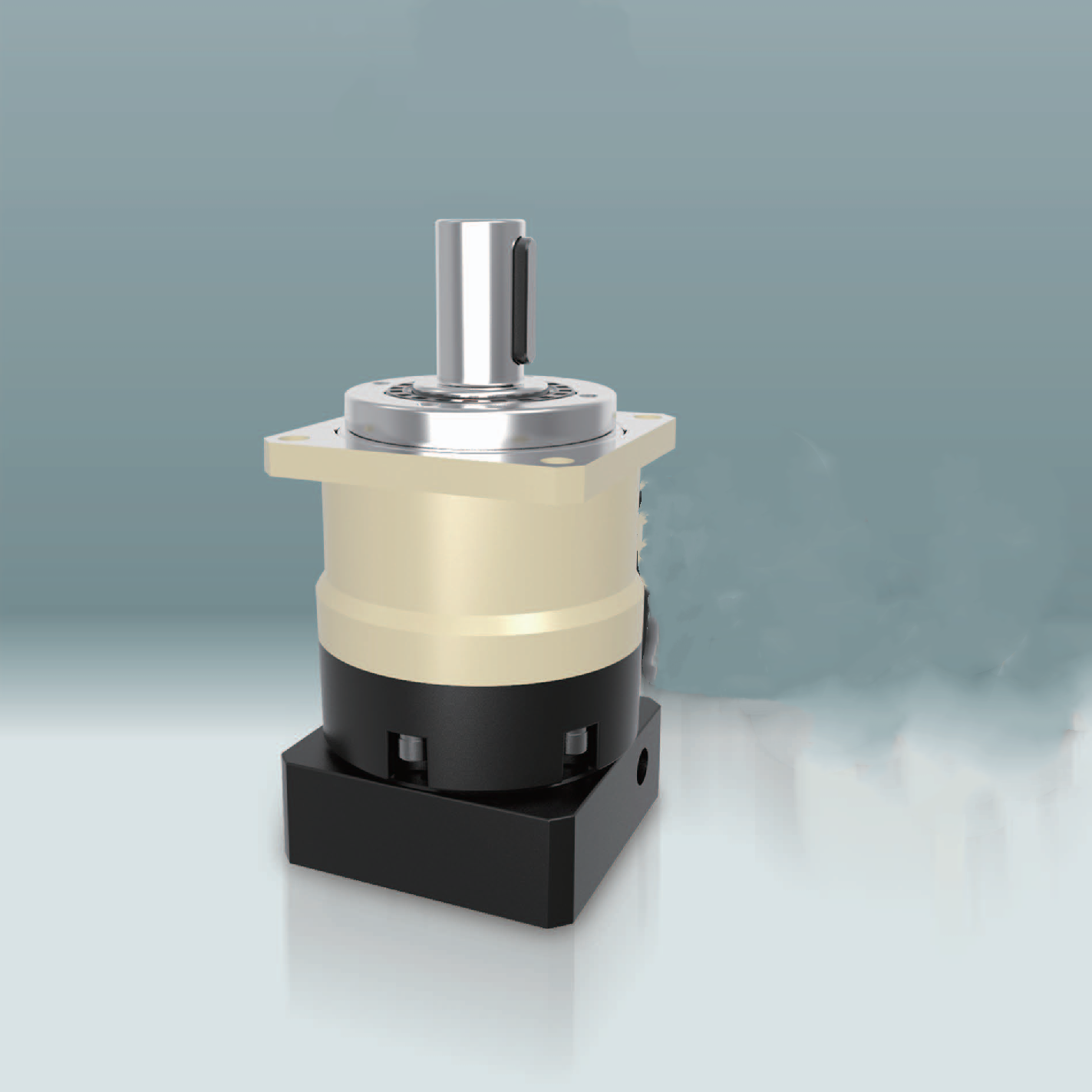

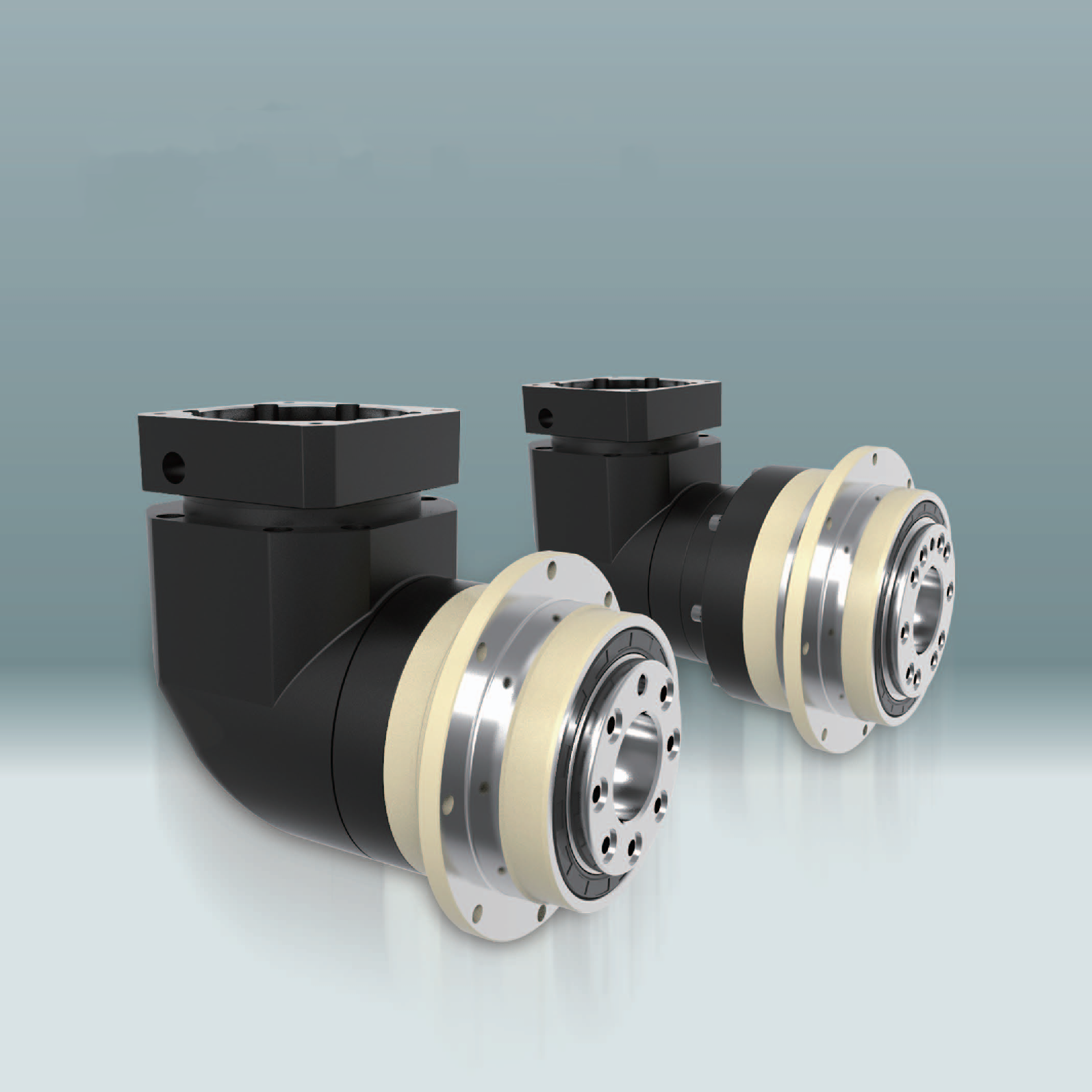

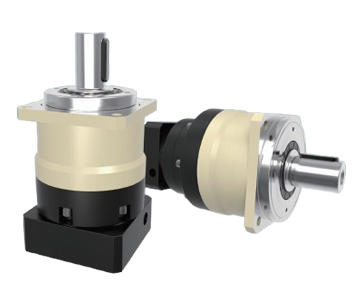

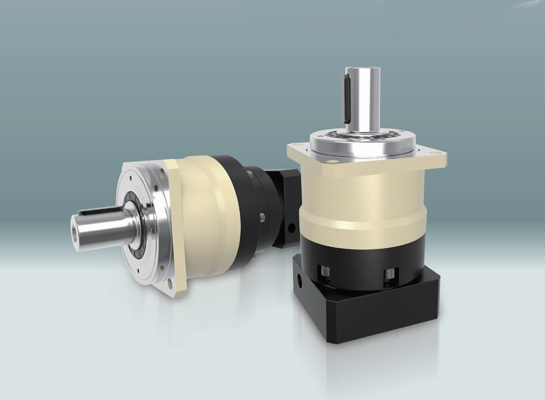

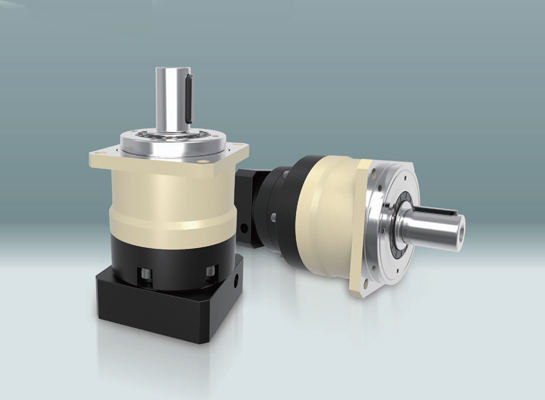

Product Display

High torque

Strong load-bearing capacity: Multiple planetary gears share the load at the same time, and the use of high-strength materials and optimized structural design enables the reducer to withstand large radial and axial loads and has a high torque output capacity. It can meet the needs of various heavy-duty working conditions, such as the lifting mechanism of heavy cranes, the drive system of large mixing equipment, etc.

High torque density: It can output a large torque in a limited space, which is very suitable for application scenarios with limited space, and helps the miniaturization and lightweight design of equipment.

High input speed: It can usually support higher input speed, generally up to 2000-8000rpm or even higher, and can be well matched with power sources such as high-speed motors or engines to meet the transmission requirements of high-speed running equipment.

Compact structure

Small size: The compact structure layout of the planetary gear makes the overall size of the reducer relatively small, which is convenient for installation in equipment with limited space, such as the joints of robots and the narrow space of automated production lines.

Light weight: The use of lightweight materials and optimized design reduces the weight of the reducer while ensuring strength and performance, which is convenient for transportation and installation, and also helps to reduce the overall weight of the equipment.

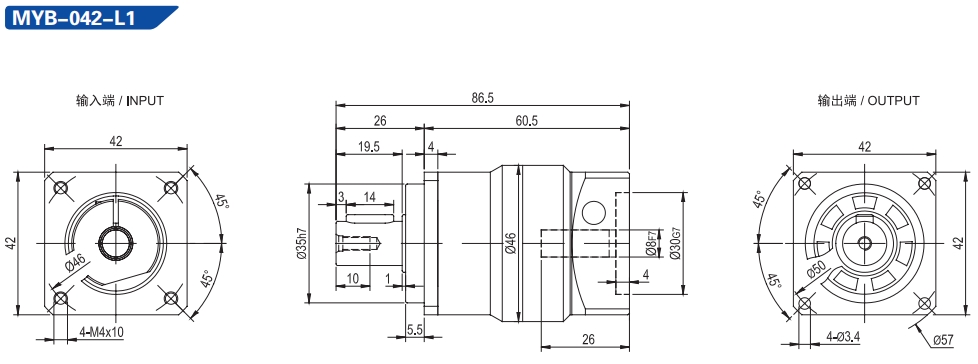

Size & Interface

Quality Control

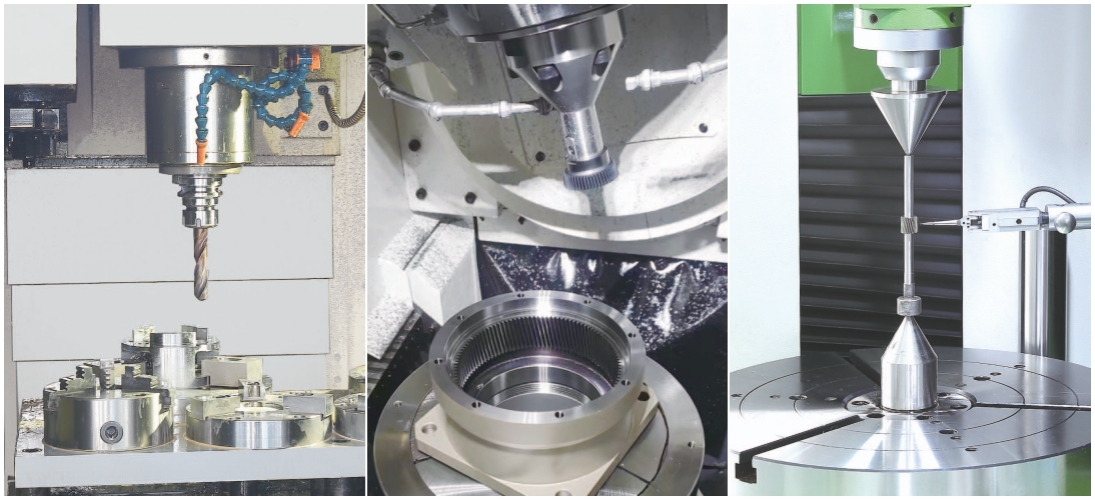

Our company has a complete production and manufacturing chain of servo reducers, equipped with processing equipment such as Kashifuji gear hobbing machines imported from Japan, CNC gear shaping machines from Mitsubishi Heavy Industries of Japan, and DMG machining centers from Germany. It is also equipped with a series of precision gear testing equipment such as Japan's TTI gear tester, Harbin Group's universal gear measuring instrument, and Hexagon three-coordinate measuring instrument. With strong manufacturing and testing control capabilities, we can quickly provide various types of precision servo planetary reducers for customers in different fields.

Application Cases

The products are widely used in automation industry, industrial robots, metallurgy and mining, beer and beverage, tobacco and light industry, environmental protection engineering, warehousing and logistics, plastic machinery, lifting and transportation, three-dimensional parking, automobile manufacturing, textiles, food, ceramics and other fields.