Product Description

This series of motors integrates precision planetary reducers, torque motors, and professional servo drives to form a drive-control integrated micro servo joint. The joints are connected in series through a bus, the wiring is simple and easy to operate, and the failure rate of the whole machine is low; the product is small in size and has a large torque, which is particularly suitable for multi-joint combination application scenarios such as bionic robots, bionic animals, and educational robotic arms; at the same time, due to its high cost-effectiveness and stable performance, it can replace a variety of brushless motors and high-torque servos.

Product parameters

| Model | YP05 | YP08/YP08D | YP11/YP11D | YP11L |

| Motor type | Brushless torque motor | |||

| Reducer type | Planetary reducer | |||

| Diameter | 32mm | 40mm | 52mm | 52mm |

| Length | 33.4mm | 52/48mm | 64/61mm | 82mm |

| Weight | 82g | 190/199g | 391/436g | 517g |

| Reduction ratio | 6:01 | 36:01:00 | ||

| Backlash | 12arcmin | |||

| Noise | <70db | |||

| Temperature range | -20~80℃ | |||

| Operating voltage | 24v | |||

| Maximum power | 35w | 36w | 60w | 72w |

| Rated speed | 50rpm | |||

| Rated torque | 0.2nm | 1.0nm | 6.6nm | 12nm |

| Peak torque | 0.48nm | 2.2nm | 14nm | 18nm |

| Torque coefficient | 0.2nm/a | 1.1nm/a | 2.2nm/a | 6nm/a |

| Axial bearing capacity | 1284N | 1605N | 1605N | |

| Radial bearing capacity | 2520N | 3150N | 3150N | |

Product Display

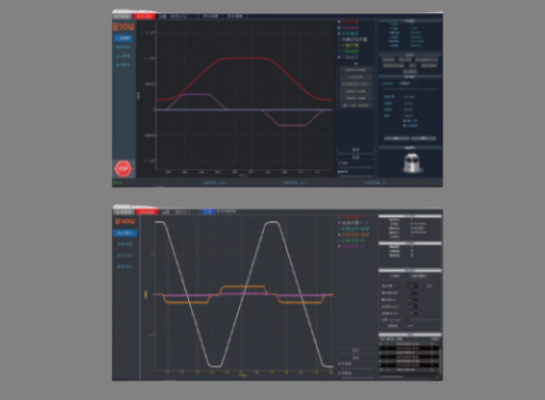

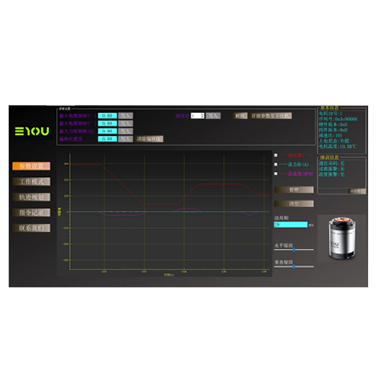

Software operation interface:

A new generation of micro-integrated flexible servo joints, with internally integrated high-precision reducers, high-energy density torque motors, and high-performance drives. The products have high integration, high precision, and stable performance, and are particularly suitable for products such as bionic robots and robotic arms.

UBUNTU and WINDOWS versions of the host computer are provided to facilitate users to quickly verify. At the same time, C/C++API is provided, which can integrate LINUX-

(ROS)\WINDOWS systems to achieve rapid mass production of products.

Complete parameter setting

Internally integrated trajectory profile working mode, acceleration and deceleration, speed limit, torque limit, and temperature limit can all be set;

Current loop frequency 20khz, speed loop 10kHz, position loop 1kHz, all three loop parameters are open, and various working modes can be freely realized.

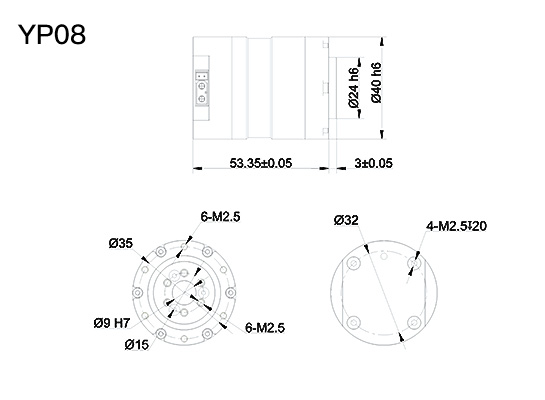

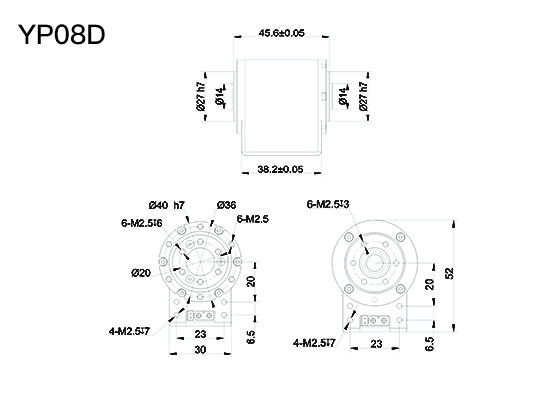

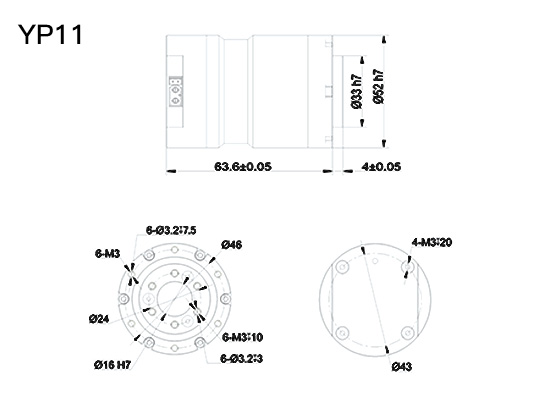

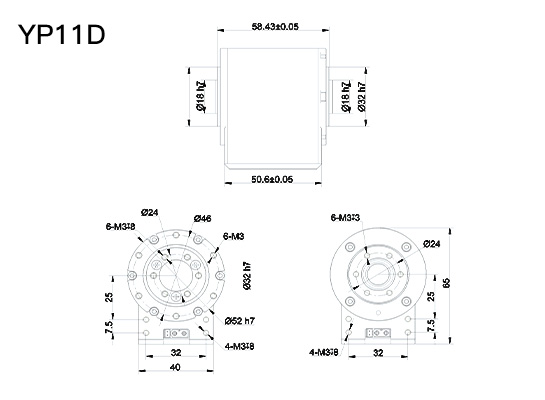

Size & Interface

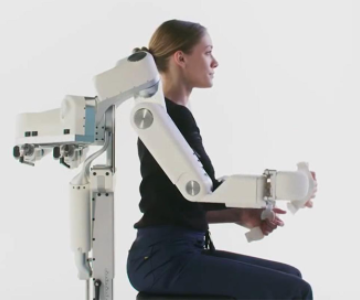

Application Cases

The servo module adopts a hollow design, which is particularly suitable for the six-axis collaborative robot arm. The high-speed closed-loop cycle of the module can flexibly control the rigidity and precision of the robot arm, providing a high-performance body for the host computer. The robot joints with different loads can be freely combined, and the body and software technical support are provided, so that customers can quickly build their own robot system.