Product Description

TE12H ball screw linear sliding table works by electromagnetic principle, with stator and moving parts. The stator is composed of an iron core and a coil, which is energized to produce a magnetic field, and the moving parts are composed of magnets and conductors, which are moved by the magnetic force of the stator magnetic field, and the direction of movement is related to the direction of the stator coil current, and the moving parts can be reversed by changing the direction of the current. In practical applications, with the help of the encoder for position feedback, to achieve high-precision position control, but also by changing the size and direction of the current, to achieve different motion speed and acceleration, and can be combined with PLC and other automatic control equipment, to achieve the efficient operation of automated production lines.

Product parameters

| Electric machine | MCL-045-C2 |

|---|---|

| actuate | 3A |

| Sustained thrust | 92N |

| Peak thrust | 310N |

| Weight of moving parts | 3.4KG |

| Maximum load | 15KG |

| Maximum speed | 3m/s |

| Raster repeated positioning accuracy | ±1um (within 1000mm stroke) |

| Magnetic grid repeated positioning accuracy | ±3um (within 1000mm stroke) |

| straightness | ±2um/300mm |

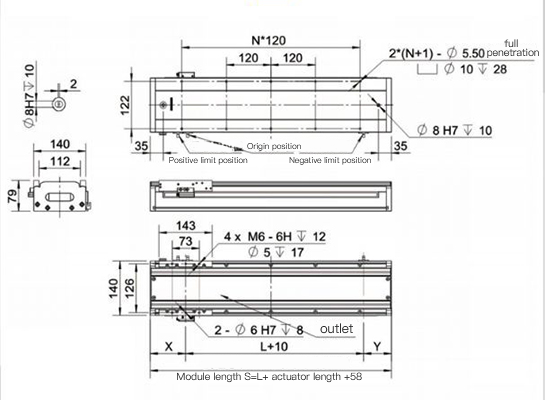

| journey | 50-2000mm |

Product Display

Scope of application: 3D printing, Aurora welding, dispensing machine, CNC machine tool, spraying machine and other industrial applications

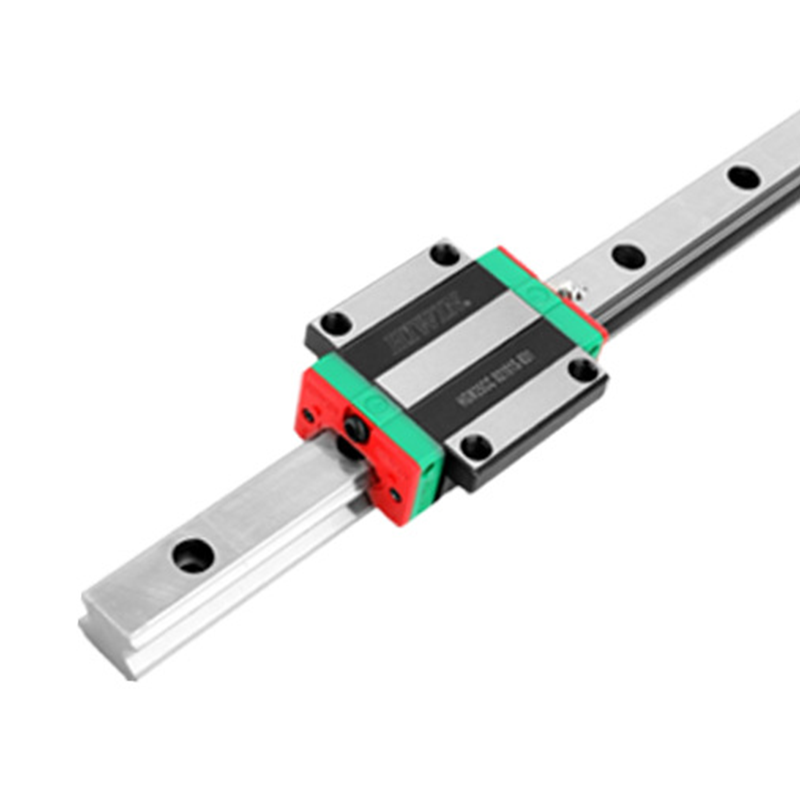

Product function: a highly integrated transmission platform, also known as linear module, cartesian robot, linear slide table and other linear motor drive, equipped with grating positioning, fast response, high stability, high reliability;

Can be used with a variety of motors (such as servo motors, stepper motors), through the coupling connection, convenient to achieve different speed, torque and control requirements, and can be flexible installation and layout according to the specific application scenario;

The speed is fast, the maximum movement speed can reach 3m/s, and the precision of movement is high, and the acceleration is also high;

Overall modular design, compact structure, easy to expand;

No back backlash error, no contact operation of moving stator;

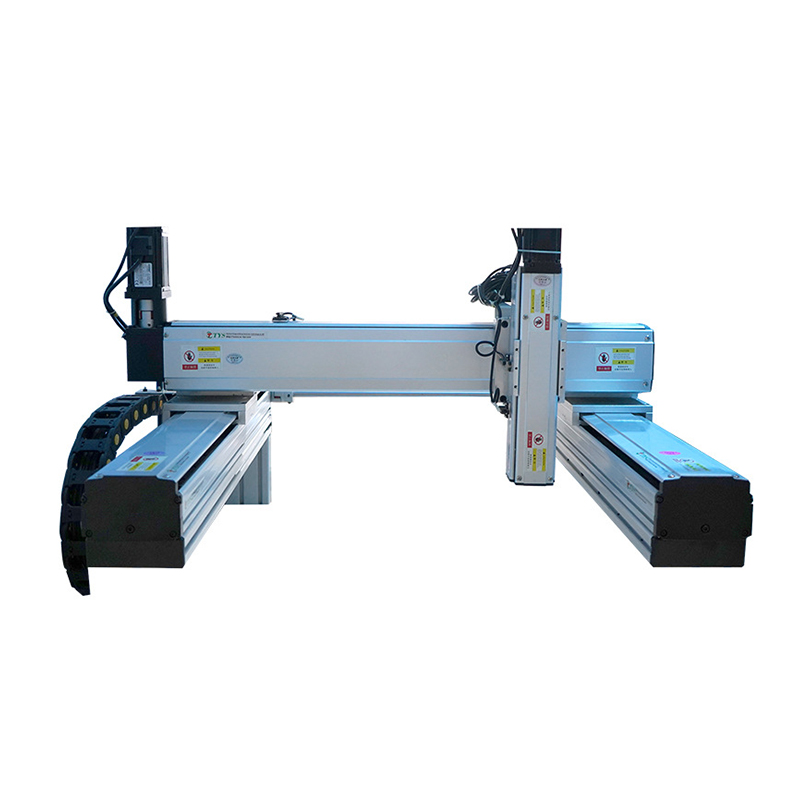

Allows coaxial multiple independent actuators, can be combined into robotic arms, XY cross and gantry system;

Long travel, the maximum travel can reach more than 2m;

Smooth movement, no wearing parts, there is little need for maintenance, long service life;

TCH-B110 linear motor module, load up to 15kg, maximum speed up to 3m/s;

A variety of drives are freely available from Panasonic Kotron Renishaw encoder

Panasonicdrive Panasonicdrive:It is widely used in the money motor industry and is highly praised by customers.

Servotronix High innovation drive:Manufactured by Servotronix Motlon ControI(STX) LTD., the CKHD series supports virtually any servo motor and countermodulation type, as well as any 10 requirements, and can be rapidly integrated with a wide range of equipment and application projects.

Renishaw encoder:Nisho Method is needed to provide solutions for a wide range of motion control box metering applications. Can provide a wide range of first market magnetic rotary encoders, linear magnetic slow and magnetic bad encoders.

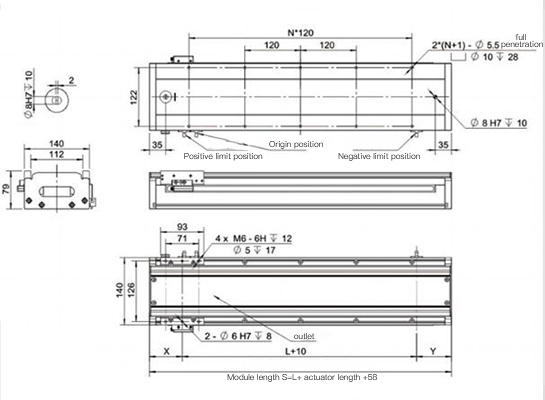

Size & Interface

Application Cases

Suzhou Tongyousheng Electronic Technology Co., LTD., specializing in the production of servo electric cylinder, linear slide module, servo press, multi-dimensional free movement platform robot, robot series products. And provide Mitsubishi, Panasonic industrial control products, PLC, servo motor, inverter, touch screen, guide rail, screw, reducer series products.

Company Information

The company introduces foreign advanced technology, has specialized production equipment, advanced CNC processing equipment, high-precision test equipment, and has senior mechanical transmission designers, advanced design software, after years of struggle and struggle, Suzhou Tongyousheng Electronic Technology Co., Ltd. has established a leading advantage of "large scale, high output, stable quality" in the industry. Determined to strive for the development of Industry 4.0, we cooperate with a number of state-owned enterprises, top 500 units and universities. To provide customers with simple operation, excellent efficiency, stable performance, reasonable price of product equipment.

Cooperative partner

Service

Pre-sales -- Help reasonable selection: project evaluation engineers docking, in-depth communication to understand the use of conditions, to confirm the appropriate selection and specifications, to give customers reasonable suggestions, effectively avoid problems in production

Sales -- Ensure production delivery: dedicated engineers and business specialists docking, project managers to process control, active communication and interaction, timely detection of problems and timeliness communication, for the production delivery escort

After-sales -- Timely response processing: after-sales engineering personnel docking, the same day response; And timely to the scene to confirm, discuss, solve and deal with problems, to meet customer production needs, to avoid downtime and production