Product Description

High performance planetary gearbox - compact design for efficient output

Functional Features

PLANETARY GEARBOX MODULE

Product parameters

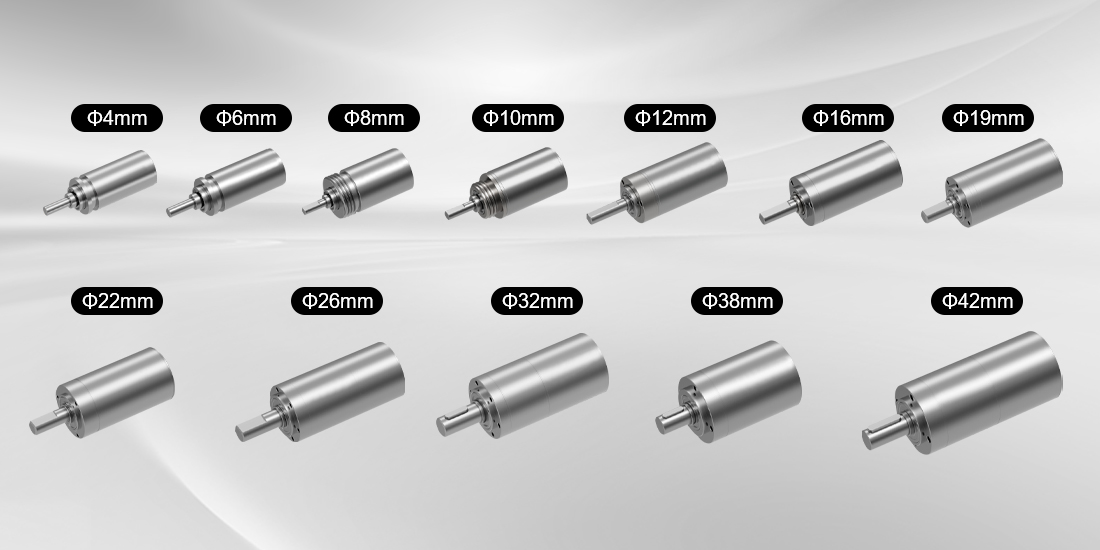

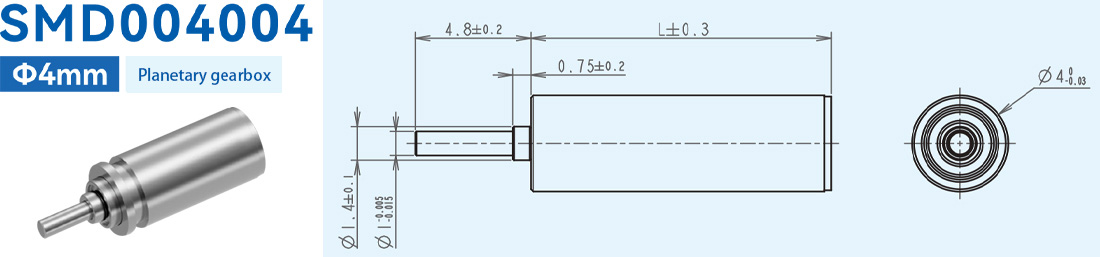

Technical data | |||||

Gearbox series | 1 | 2 | 3 | 4 | |

Continuous output torque (Max) | Nm | 0.001 | 0.002 | 0.006 | 0.015 |

Instantaneous allowable moment (Max) | Nm | 0.002 | 0.003 | 0.008 | 0.02 |

Reduction ratio | / | 4.8 | 230 | 110.6 | 531 |

External diameter | mm | 4 | 4 | 4 | 4 |

Gearbox length L1 | mm | 7.7 | 9.3 | 10.9 | 12.5 |

Maximum efficiency | % | 87 | 76 | 70 | 65 |

Recommended temperature range | ℃ | -40~+80 | -40~+80 | -40~+80 | -40~+80 |

Gearbox weight (Max) | G | 1 | 1.2 | 1.3 | 1.5 |

Maximum transmission power (continuous) | W | 0.15 | 0.17 | 0.12 | 0.08 |

Maximum transmission power (instantaneous) | W | 2 | 0.21 | 0.15 | 0.1 |

Average empty return of no load | ° | 5 | 5 | 5 | 5 |

Maximum axial load (dynamic) | N | 5 | 5 | 5 | 5 |

Maximum radial load (4mm from flange) | N | 3 | 3 | 4 | 4 |

Output bearing | Ball bearing | Ball bearing | Ball bearing | Ball bearing | |

Axial clearance | mm | 0~0.1 | 0~0.1 | 0~0.1 | 0~0.1 |

Note: The above data does not include motor, gearbox and motor sales, the specific parameters can be customized according to customer requirements | |||||

Modular assembly | |||||

Combination product | Model number | series | |||

1 | 2 | 3 | 4 | ||

Length(mm) | |||||

Dc motor | 0408 φ4 graphite brush | 15.8 | 17.4 | 19 | 20.6 |

0412φ4 graphite brush | 20 | 21.6 | 23.2 | 24.8 | |

Brushless machine | MC0409 φ4mm hollow cup brushless motor | 16.2 | 17.8 | 19.4 | 21 |

encoder | / | ||||

Typical application product data | |||||||||||

Model number | Rated voltage (V) | No-load data | Load data | Total length | Gear box rated allowable torque (NM) | Gear box instantaneous torque (NM) | Reduction ratio | Reducer length L1(mm) | |||

No-load speed | No-load current | Load speed | Load current | Torque | |||||||

SMD004004-4.8-X | 5 | 9375 | 140 | 6250 | 180 | 0.0002 | 16.2 | 0.001 | 0.002 | 4.8 | 7.7 |

SMD004004-23-X | 5 | 1957 | 140 | 1304 | 180 | 0.0003 | 17.8 | 0.002 | 0.003 | 23 | 9.3 |

SMD004004-111-X | 5 | 407 | 140 | 271 | 180 | 0.0015 | 19.4 | 0.006 | 0.008 | 110.6 | 10.9 |

SMD004004-531-X | 5 | 85 | 140 | 57 | 180 | 0.0069 | 21 | 0.015 | 0.02 | 530.8 | 12.5 |

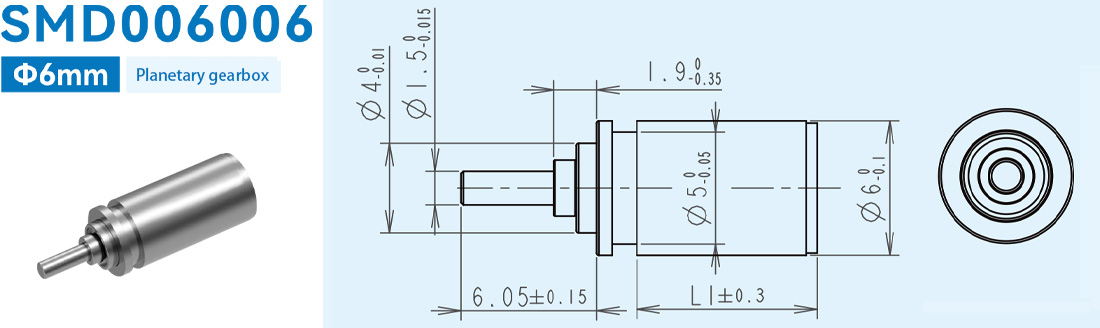

Technical data | ||||||

Gearbox series | 1 | 2 | 3 | 4 | 5 | |

Continuous output torque (Max) | Nm | 0.002 | 0.005 | 1 | 0.03 | 0.03 |

Instantaneous allowable moment (Max) | Nm | 0.005 | 0.01 | 0.02 | 0.06 | 0.06 |

Reduction ratio | / | 3.9 | 15 | 57 | 221 | 854 |

External diameter | mm | 6 | 6 | 6 | 6 | 6 |

Gearbox length L1 | mm | 5.8 | 8.2 | 10.6 | 13 | 15.4 |

Maximum efficiency | % | 83 | 69 | 57 | 65 | 47 |

Recommended temperature range | ℃ | -30~+85 | -30~+85 | -30~+85 | -30~+85 | -30~+85 |

Gearbox weight (Max) | G | 1.7 | 2.1 | 2.5 | 2.9 | 3.3 |

Maximum transmission power (continuous) | W | 63 | 0.39 | 0.2 | 0.15 | 0.04 |

Maximum transmission power (instantaneous) | W | 79 | 0.49 | 25 | 0.18 | 0.05 |

Average empty return of no load | ° | 1.8 | 2 | 2.2 | 2.5 | 2.8 |

Maximum axial load (dynamic) | N | 5 | 5 | 5 | 5 | 5 |

Maximum radial load (4mm from flange) | N | 5 | 6 | 7 | 8 | 8 |

Output bearing | Ball bearing | Ball bearing | Ball bearing | Ball bearing | Ball bearing | |

Axial clearance | mm | 0~0.1 | 0~0.1 | 0~0.1 | 0~0.1 | 0~0.1 |

Note: The above data does not include motor, gearbox and motor sales, the specific parameters can be customized according to customer requirements | ||||||

Modular assembly | ||||||

Combination product | Model number | series | ||||

1 | 2 | 3 | 4 | 5 | ||

Length(mm) | ||||||

Dc motor | / | |||||

Brushless machine | MO0623 Φ6mm hollow cup brushless motor | 28 | 30 | 33 | 35 | 37 |

encoder | CB-ST-6 | Magnetic knitting | ||||

Typical application product data | |||||||||||

Model number | Rated voltage (V) | No-load data | Load data | Total length | Gear box rated allowable torque (NM) | Gear box instantaneous torque (NM) | Reduction ratio | Reducer length L1(mm) | |||

No-load speed | No-load current | Load speed | Load current | Torque | |||||||

SMD006006-04-X | 12 | 16437 | 150 | 12133 | 350 | 0.002 | 28.8 | 0.002 | 0.005 | 3.9 | 5.8 |

SMD006006-15-X | 12 | 4261 | 150 | 3146 | 355 | 0.005 | 31.2 | 0.005 | 0.01 | 14.9 | 8.2 |

SMD006006-57-X | 12 | 1105 | 160 | 816 | 360 | 0.01 | 33.6 | 0.01 | 0.02 | 57.4 | 10.6 |

SMD006006-221-X | 12 | 286 | 170 | 211 | 365 | 0.03 | 36 | 0.03 | 0.06 | 221.3 | 13 |

SMD006006-854-X | 12 | 74 | 180 | 55 | 370 | 0.03 | 38.4 | 3 | 0.06 | 853.7 | 15.4 |

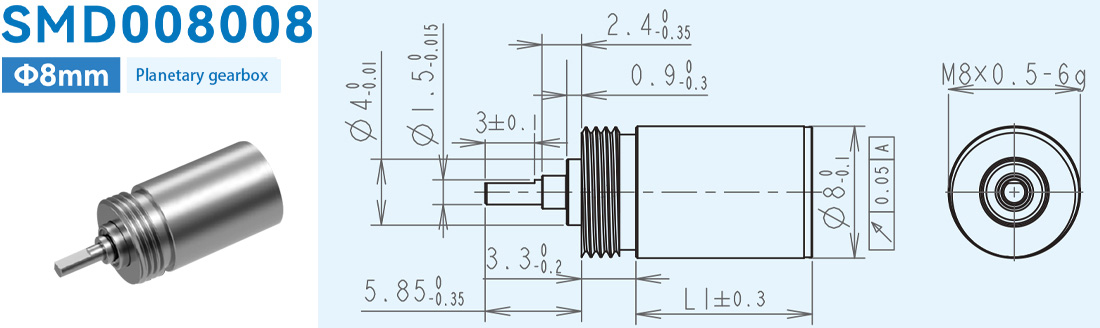

Technical data | ||||||

Gearbox series | 1 | 2 | 3 | 4 | 5 | |

Continuous output torque (Max) | Nm | 0.01 | 0.02 | 6 | 0.08 | 0.1 |

Instantaneous allowable moment (Max) | Nm | 0.015 | 0.03 | 0.09 | 0.12 | 0.15 |

Reduction ratio | / | 4 | 16,36 | 64216 | 2561296 | 1024 |

External diameter | mm | 8 | 8 | 8 | 8 | 8 |

Gearbox length L1 | mm | 5.5 | 8.1 | 10.7 | 13.3 | 15.9 |

Maximum efficiency | % | 90 | 81 | 73 | 65 | 59 |

Recommended temperature range | ℃ | -30~+85 | -30~+85 | -30~+85 | -30~+85 | -30~+85 |

Gearbox weight (Max) | G | 2.6 | 3.2 | 3.8 | 4.4 | 5 |

Maximum transmission power (continuous) | W | 84 | 52 | 39 | 0.13 | 0.04 |

Maximum transmission power (instantaneous) | W | 1.05 | 0.65 | 49 | 0.16 | 0.05 |

Average empty return of no load | ° | 1.8 | 2 | 2.2 | 2.5 | 3 |

Maximum axial load (dynamic) | N | 5 | 5 | 5 | 5 | 5 |

Maximum radial load (4mm from flange) | N | 5 | 6 | 7 | 8 | 8 |

Output bearing | Ball bearing | Ball bearing | Ball bearing | Ball bearing | Ball bearing | |

Axial clearance | mm | 0~0.1 | 0~0.1 | 0~0.1 | 0~0.1 | 0~0.1 |

Note: The above data does not include motor, gearbox and motor sales, the specific parameters can be customized according to customer requirements | ||||||

Modular assembly | ||||||

Combination product | Model number | series | ||||

1 | 2 | 3 | 4 | 5 | ||

Length(mm) | ||||||

Dc motor | MP0816φ8mm graphite brush | 22.5 | 25.1 | 27.7 | 30.3 | 32.9 |

Brushless machine | MO0832φ8mm hollow cup brushless motor | 37.5 | 40.1 | 42.7 | 45.3 | 47.9 |

MC0824 medium 8mm hollow cup brushless motor | 22.5 | 32.1 | 34.7 | 37.3 | 39.9 | |

encoder | CB-ST-8 | Magnetic knitting | ||||

Typical application product data | |||||||||||

Model number | Rated voltage (V) | No-load data | Load data | Total length | Gear box rated allowable torque (NM) | Gear box instantaneous torque (NM) | Reduction ratio | Reducer length L1(mm) | |||

No-load speed | No-load current | Load speed | Load current | Torque | |||||||

SMD008008-04-X | 12 | 9625 | 120 | 6375 | 0.55 | 0.01 | 29.5 | 0.01 | 0.015 | 4 | 5.5 |

SMD008008-16-X | 12 | 2406 | 130 | 1594 | 0.6 | 0.03 | 32.1 | 0.02 | 0.03 | 16 | 8.1 |

SMD008008-36-X | 12 | 1069 | 130 | 708 | 0.6 | 0.01 | 0.008 | 0.012 | 36 | ||

SMD008008-64-X | 12 | 602 | 140 | 398 | 0.6 | 0.06 | 34.7 | 0.06 | 0.09 | 64 | 10.7 |

SMD008008-216-X | 12 | 178 | 140 | 118 | 0.6 | 0.02 | 0.02 | 0.03 | 216 | ||

SMD008008-256-X | 12 | 150 | 150 | 100 | 0.65 | 0.08 | 37.3 | 0.08 | 0.12 | 256 | 13.3 |

SMD008008-1296-X | 12 | 30 | 150 | 20 | 65 | 0.04 | 0.04 | 0.06 | 1296 | ||

SMD008008-1024-X | 12 | 38 | 160 | 25 | 0.7 | 0.1 | 39.9 | 1 | 0.15 | 1024 | 15.9 |

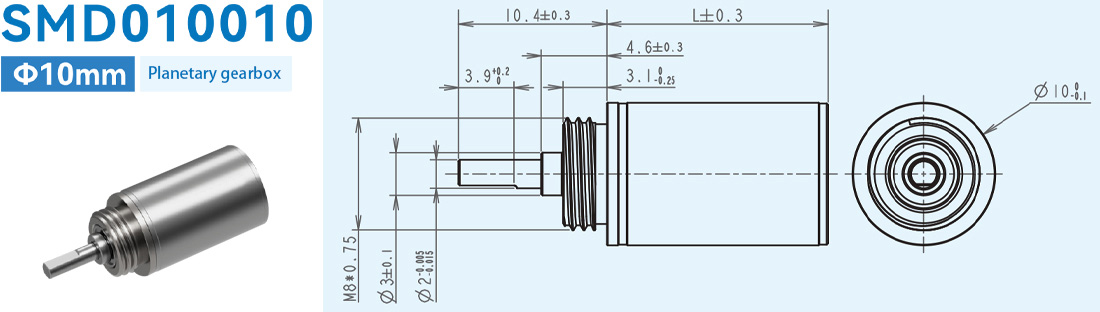

Technical data | ||||||

Gearbox series | 1 | 2 | 3 | 4 | 5 | |

Continuous output torque (Max) | Nm | 0.01 | 0.03 | 0.1 | 0.15 | 0.15 |

Instantaneous allowable moment (Max) | Nm | 0.02 | 0.05 | 0.15 | 0.2 | 0.2 |

Reduction ratio | / | 4 | 16 | 64 | 256 | 1024 |

External diameter | mm | 10 | 10 | 10 | 10 | 10 |

Gearbox length L1 | mm | 8.6 | 12.1 | 15.5 | 18.5 | 21.9 |

Maximum efficiency | % | 90 | 80 | 70 | 60 | 55 |

Recommended temperature range | ℃ | -40~+100 | -40~+100 | -40~+100 | -40~+100 | -40~+100 |

Gearbox weight (Max) | G | 6.6 | 7 | 7.6 | 8.1 | 8.6 |

Maximum transmission power (continuous) | W | 1.6 | 1.2 | 1 | 0.4 | 0.1 |

Maximum transmission power (instantaneous) | W | 2 | 1.5 | 1.3 | 0.5 | 0.13 |

Average empty return of no load | ° | 1.5 | 1.8 | 2 | 2.2 | 2.5 |

Maximum axial load (dynamic) | N | 5 | 5 | 5 | 5 | 5 |

Maximum radial load (4mm from flange) | N | 5 | 10 | 15 | 20 | 25 |

Output bearing | Ball bearing | Ball bearing | Ball bearing | Ball bearing | Ball bearing | |

Axial clearance | mm | <0.1 | <0.1 | <0.1 | <0.1 | <0.1 |

Note: The above data does not include motor, gearbox and motor sales, the specific parameters can be customized according to customer requirements | ||||||

Modular assembly | ||||||

Combination product | Model number | series | ||||

1 | 2 | 3 | 4 | 5 | ||

Length(mm) | ||||||

Dc motor | 1015φ10mm graphite brush | 23.6 | 27.1 | 30.5 | 33.5 | 36.9 |

1020 φ10mm graphite brush | 29.3 | 32.8 | 36.2 | 39.2 | 42.6 | |

Brushless machine | 1026φ10mm hollow cup brushless motor | 36.6 | 40.1 | 43.5 | 46.5 | 49.9 |

encoder | CB-ST-10 | Magnetic knitting | ||||

Typical application product data | |||||||||||

Model number | Rated voltage (V) | No-load data | Load data | Total length | Gear box rated allowable torque (NM) | Gear box instantaneous torque (NM) | Reduction ratio | Reducer length L1(mm) | |||

No-load speed | No-load current | Load speed | Load current | Torque | |||||||

SMD010010-4-X | 12 | 9167 | 120 | 7361 | 1 | 0.005 | 36.6 | 1 | 0.02 | 4 | 8.6 |

SMD010010-5-X | 12 | 6226 | 120 | 5000 | 1 | 0.007 | 5 | ||||

SMD010010-16-X | 12 | 2063 | 120 | 1656 | 1 | 0.019 | 40.1 | 0.03 | 0.05 | 16 | 12.1 |

SMD010010-20-X | 12 | 1650 | 120 | 1325 | 1 | 0.024 | 20 | ||||

SMD010010-25-X | 12 | 1320 | 120 | 1060 | 1 | 0.03 | 25 | ||||

SMD010010-64-X | 12 | 516 | 120 | 414 | 1 | 0.067 | 43.5 | 0.1 | 0.15 | 64 | 15.5 |

SMD010010-80-X | 12 | 413 | 120 | 331 | 1 | 0.084 | 80 | ||||

SMD010010-100-X | 12 | 330 | 120 | 265 | 1 | 0.105 | 100 | ||||

SMD010010-125-X | 12 | 264 | 120 | 212 | 1 | 0.131 | 125 | ||||

SMD010010-256-X | 12 | 129 | 120 | 116 | 0.8 | 0.15 | 46.5 | 0.15 | 0.2 | 256 | 18.5 |

SMD010010-320-X | 12 | 103 | 120 | 95 | 8 | 0.15 | 320 | ||||

SMD010010-400-X | 12 | 83 | 120 | 78 | 8 | 0.15 | 400 | ||||

SMD010010-500-X | 12 | 66 | 120 | 63 | 0.8 | 0.15 | 500 | ||||

SMD010010-625-X | 12 | 53 | 120 | 51 | 0.8 | 0.15 | 625 | ||||

SMD010010-1024-X | 12 | 32 | 120 | 31 | 0.8 | 0.15 | 49.9 | 0.15 | 0.2 | 1024 | 21.9 |

SMD010010-1280-X | 12 | 26 | 120 | 25 | 0.8 | 0.15 | 1280 | ||||

SMD010010-1600-X | 12 | 21 | 120 | 20 | 0.8 | 0.15 | 1600 | ||||

SMD010010-2000-X | 12 | 17 | 120 | 16 | 0.8 | 0.15 | 2000 | ||||

SMD010010-2500-X | 12 | 13 | 120 | 13 | 0.8 | 0.15 | 2500 | ||||

SMD010010-3125-X | 12 | 11 | 120 | 10 | 0.8 | 0.15 | 3125 | ||||

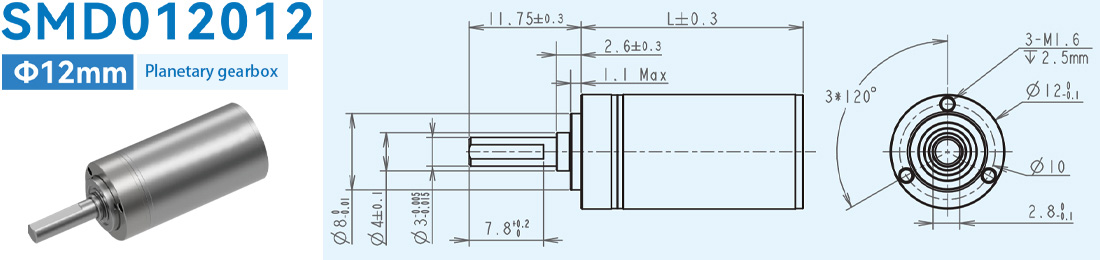

Technical data | ||||

Gearbox series | 2 | 3 | 4 | |

Continuous output torque (Max) | Nm | 0.25 | 0.3 | 0.35 |

Instantaneous allowable moment (Max) | Nm | 0.3 | 0.38 | 0.41 |

Reduction ratio | / | 16,21,26,28,35 | 62,83,103,111,138,150,172,186,231 | 243,326,406,439,546,590,679,734, |

External diameter | mm | 12 | 12 | 12 |

Gearbox length L1 | mm | 17.5 | 23.3 | 27.8 |

Maximum efficiency | % | 75 | 65 | 55 |

Recommended temperature range | ℃ | -40~+100 | -40~+100 | -40~+100 |

Gearbox weight (Max) | G | 12.4 | 15.5 | 18.6 |

Maximum transmission power (continuous) | W | 2.2 | 1.1 | 0.6 |

Maximum transmission power (instantaneous) | W | 2.8 | 1.4 | 0.8 |

Average empty return of no load | ° | 1.5 | 1.8 | 2.1 |

Maximum axial load (dynamic) | N | 20 | 20 | 20 |

Maximum radial load (4mm from flange) | N | 45 | 60 | 60 |

Output bearing | Ball bearing | Ball bearing | Ball bearing | |

Axial clearance | mm | <0.1 | <0.1 | <0.1 |

Note: The above data does not include motor, gearbox and motor sales, the specific parameters can be customized according to customer requirements | ||||

Modular assembly | ||||

Combination product | Model number | series | ||

2 | 3 | 4 | ||

Length(mm) | ||||

Dc motor | 1220φ12mm graphite brush | 37.5 | 43.3 | 47.8 |

1228φ12mm graphite brush | 45.7 | 51.5 | 56 | |

Brushless machine | 1226φ12mm hollow cup brushless motor | 43.6 | 49.4 | 53.9 |

1232φ12mm hollow cup brushless motor | 49.5 | 55.3 | 59.8 | |

encoder | CB-ST-8 | Magnetic knitting | ||

Typical application product data | |||||||||||

Model number | Rated voltage (V) | No-load data | Load data | Total length | Gear box rated allowable torque (NM) | Gear box instantaneous torque (NM) | Reduction ratio | Reducer length L1(mm) | |||

No-load speed | No-load current | Load speed | Load current | Torque | |||||||

SMD012012-16-X | 12 | 1836 | 117 | 1284 | 1 | 0.034 | 43.5 | 0.25 | 0.3 | 16 | 17.5 |

SMD012012-21-X | 12 | 1365 | 117 | 955 | 1 | 0.042 | 21 | ||||

SMD012012-26-X | 12 | 1098 | 117 | 768 | 1 | 0.052 | 26 | ||||

SMD012012-28-X | 12 | 1015 | 117 | 710 | 1 | 0.056 | 28 | ||||

SMD012012-35-X | 12 | 816 | 117 | 571 | 1 | 0.07 | 35 | ||||

SMD012012-62-X | 12 | 465 | 117 | 325 | 1 | 0.1 | 49.3 | 0.3 | 0.38 | 62 | 23.3 |

SMD012012-83-X | 12 | 346 | 117 | 242 | 1 | 0.134 | 83 | ||||

SMD012012-103-X | 12 | 278 | 117 | 195 | 1 | 0.167 | 103 | ||||

SMD012012-111-X | 12 | 257 | 117 | 180 | 1 | 0.181 | 111 | ||||

SMD012012-138-X | 12 | 207 | 117 | 145 | 1 | 0.225 | 138 | ||||

SMD012012-150-X | 12 | 191 | 117 | 134 | 1 | 0.243 | 150 | ||||

SMD012012-172-X | 12 | 166 | 117 | 116 | 1 | 0.279 | 172 | ||||

SMD012012-186-X | 12 | 154 | 117 | 108 | 1 | 0.302 | 186 | ||||

SMD012012-231-X | 12 | 124 | 117 | 89 | 1 | 0.35 | 231 | ||||

SMD012012-243-X | 12 | 118 | 117 | 80 | 0.8 | 0.35 | 53.8 | 0.35 | 0.35 | 243 | 27.8 |

SMD012012-326-X | 12 | 88 | 117 | 67 | 0.8 | 0.35 | 326 | ||||

SMD012012-406-X | 12 | 70 | 117 | 57 | 0.8 | 0.35 | 406 | ||||

SMD012012-439-X | 12 | 65 | 117 | 54 | 0.8 | 0.35 | 439 | ||||

SMD012012-546-X | 12 | 52 | 117 | 45 | 0.8 | 0.35 | 546 | ||||

SMD012012-590-X | 12 | 48 | 117 | 42 | 0.8 | 0.35 | 590 | ||||

SMD012012-679-X | 12 | 42 | 117 | 38 | 0.8 | 0.35 | 679 | ||||

SMD012012-734-X | 12 | 39 | 117 | 35 | 0.8 | 0.35 | 734 | ||||

SMD012012-794-X | 12 | 36 | 117 | 33 | 0.8 | 0.35 | 794 | ||||

SMD012012-913-X | 12 | 31 | 117 | 29 | 0.8 | 0.35 | 913 | ||||

SMD012012-987-X | 12 | 29 | 117 | 27 | 0.8 | 0.35 | 987 | ||||

SMD012012-1135-X | 12 | 25 | 117 | 23 | 0.8 | 0.35 | 1135 | ||||

SMD012012-1227-X | 12 | 23 | 117 | 21 | 0.8 | 0.35 | 1227 | ||||

SMD012012-1526-X | 12 | 19 | 117 | 18 | 0.8 | 0.35 | 1526 | ||||

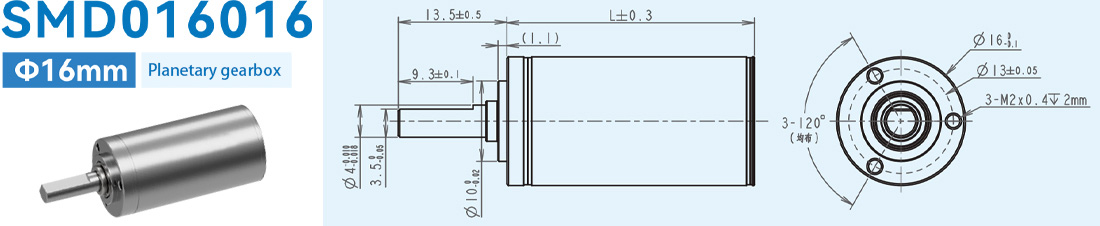

Technical data | ||||

Gearbox series | 2 | 3 | 4 | |

Continuous output torque (Max) | Nm | 0.55 | 0.8 | 0.9 |

Instantaneous allowable moment (Max) | Nm | 0.7 | 1 | 1.1 |

Reduction ratio | / | 16,21,26,28,35,44 | 62,83,103,111,138,150,172,186,231 | 243,326,406,439,546,590,679,734, |

External diameter | mm | 16 | 16 | 16 |

Gearbox length L1 | mm | 25.8 | 30.8 | 35.7 |

Maximum efficiency | % | 80 | 70 | 60 |

Recommended temperature range | ℃ | -30~+100 | -30~+100 | -30~+100 |

Gearbox weight (Max) | G | 32.8 | 36.8 | 40.8 |

Maximum transmission power (continuous) | W | 8 | 4 | 1.5 |

Maximum transmission power (instantaneous) | W | 10 | 4.4 | 1.5 |

Average empty return of no load | ° | 0.5 | 0.5 | 0.5 |

Maximum axial load (dynamic) | N | 30 | 30 | 30 |

Maximum radial load (4mm from flange) | N | 80 | 90 | 90 |

Output bearing | Ball bearing | Ball bearing | Ball bearing | |

Axial clearance | mm | 0~0.1 | 0~0.1 | 0~0.1 |

Note: The above data does not include motor, gearbox and motor sales, the specific parameters can be customized according to customer requirements | ||||

Modular assembly | ||||

Combination product | Model number | series | ||

2 | 3 | 4 | ||

Length(mm) | ||||

Dc motor | 1625 graphite brush | 50.8 | 55.8 | 60.7 |

Brushless machine | MC1628 brushless motor | 53.8 | 58.8 | 63.7 |

encoder | CB-ST-16 | Magnetic knitting | ||

Typical application product data | |||||||||||

Model number | Rated voltage (V) | No-load data | Load data | Total length | Gear box rated allowable torque (NM) | Gear box instantaneous torque (NM) | Reduction ratio | Reducer length L1(mm) | |||

No-load speed | No-load current | Load speed | Load current | Torque | |||||||

SMD016016-16 | 24 | 3000 | 150 | 2500 | 1.15 | 0.055 | 53.8 | 0.55 | 0.7 | 16 | 25.8 |

SMD016016-21 | 24 | 2286 | 150 | 1905 | 1.15 | 0.072 | 21 | ||||

SMD016016-26 | 24 | 1846 | 150 | 1538 | 1.15 | 0.089 | 26 | ||||

SMD016016-28 | 24 | 1714 | 150 | 1429 | 1.15 | 0.096 | 28 | ||||

SMD016016-35 | 24 | 1371 | 150 | 1143 | 1.15 | 0.12 | 35 | ||||

SMD016016-44 | 24 | 1091 | 150 | 909 | 1.15 | 0.151 | 44 | ||||

SMD016016-62 | 24 | 774 | 170 | 645 | 1.2 | 0.213 | 58.8 | 0.8 | 1 | 62 | 30.8 |

SMD016016-83 | 24 | 578 | 170 | 482 | 1.2 | 0.286 | 83 | ||||

SMD016016-103 | 24 | 466 | 170 | 388 | 1.2 | 0.354 | 103 | ||||

SMD016016-111 | 24 | 432 | 170 | 360 | 1.2 | 0.382 | 111 | ||||

SMD016016-138 | 24 | 348 | 170 | 290 | 1.2 | 0.475 | 138 | ||||

SMD016016-150 | 24 | 320 | 170 | 267 | 1.2 | 0.516 | 150 | ||||

SMD016016-172 | 24 | 279 | 170 | 233 | 1.2 | 0.592 | 172 | ||||

SMD016016-186 | 24 | 258 | 170 | 215 | 1.2 | 0.64 | 186 | ||||

SMD016016-231 | 24 | 208 | 170 | 173 | 1.2 | 0.795 | 231 | ||||

SMD016016-243 | 24 | 198 | 190 | 165 | 1.25 | 1.1 | 63.7 | 9 | 1.1 | 243 | 35.7 |

SMD016016-326 | 24 | 147 | 190 | 123 | 1.25 | 1.1 | 326 | ||||

SMD016016-406 | 24 | 118 | 190 | 99 | 1.25 | 1.1 | 406 | ||||

SMD016016-439 | 24 | 109 | 190 | 91 | 1.25 | 1.1 | 439 | ||||

SMD016016-546 | 24 | 88 | 190 | 73 | 1.25 | 1.1 | 546 | ||||

SMD016016-590 | 24 | 81 | 190 | 68 | 1.25 | 1.1 | 590 | ||||

SMD016016-679 | 24 | 71 | 190 | 59 | 1.25 | 1.1 | 679 | ||||

SMD016016-734 | 24 | 65 | 190 | 54 | 1.25 | 1.1 | 734 | ||||

SMD016016-794 | 24 | 60 | 190 | 50 | 1.25 | 1.1 | 794 | ||||

SMD016016-913 | 24 | 53 | 190 | 44 | 1.25 | 1.1 | 913 | ||||

SMD016016-987 | 24 | 49 | 190 | 41 | 1.25 | 1.1 | 987 | ||||

SMD016016-1135 | 24 | 42 | 190 | 35 | 1.25 | 1.1 | 1135 | ||||

SMD016016-1227 | 24 | 39 | 190 | 33 | 1.25 | 1.1 | 1227 | ||||

SMD016016-1526 | 24 | 31 | 190 | 26 | 1.25 | 1.1 | 1526 | ||||

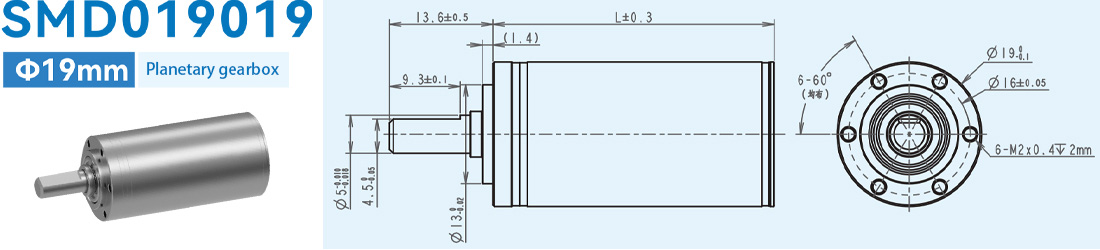

Technical data | ||||

Gearbox series | 2 | 3 | 4 | |

Continuous output torque (Max) | Nm | 0.9 | 1.6 | 2 |

Instantaneous allowable moment (Max) | Nm | 1.15 | 2 | 2.5 |

Reduction ratio | / | 16,21,26,28,35 | 62,83,103,111,138,150,172,186,231 | 243,326,406,439,546,590,679,734, |

External diameter | mm | 19 | 19 | 19 |

Gearbox length L1 | mm | 29.9 | 37 | 41 |

Maximum efficiency | % | 80 | 70 | 60 |

Recommended temperature range | ℃ | -30~+100 | -30~+100 | -30~+100 |

Gearbox weight (Max) | G | 40.2 | 60.2 | 62.2 |

Maximum transmission power (continuous) | W | 15 | 7 | 2 |

Maximum transmission power (instantaneous) | W | 19 | 9 | 3 |

Average empty return of no load | ° | 0.7 | 0.7 | 0.7 |

Maximum axial load (dynamic) | N | 40 | 40 | 40 |

Maximum radial load (4mm from flange) | N | 100 | 120 | 120 |

Output bearing | Ball bearing | Ball bearing | Ball bearing | |

Axial clearance | mm | 0~0.1 | 0~0.1 | 0~0.1 |

Note: The above data does not include motor, gearbox and motor sales, the specific parameters can be customized according to customer requirements | ||||

Modular assembly | ||||

Combination product | Model number | series | ||

2 | 3 | 4 | ||

Length(mm) | ||||

Dc motor | MP1931φ19mm graphite brush | 60.9 | 68 | 72 |

1625 graphite brush | 54.9 | 62 | 66 | |

Brushless machine | 2248 Brushless motor | 77.9 | 85 | 89 |

encoder | CB-ST-16 | Magnetic knitting | ||

Typical application product data | |||||||||||

Model number | Rated voltage (V) | No-load data | Load data | Total length | Gear box rated allowable torque (NM) | Gear box instantaneous torque (NM) | Reduction ratio | Reducer length L1(mm) | |||

No-load speed | No-load current | Load speed | Load current | Torque | |||||||

SMD019019-16 | 12 | 513 | 200 | 331 | 1.5 | 0.126 | 60.9 | 0.9 | 1.15 | 16 | 29.9 |

SMD019019-21 | 12 | 390 | 200 | 252 | 1.5 | 0.165 | 21 | ||||

SMD019019-26 | 12 | 315 | 200 | 204 | 1.5 | 0.204 | 26 | ||||

SMD019019-28 | 12 | 293 | 200 | 189 | 1.5 | 0.22 | 28 | ||||

SMD019019-35 | 12 | 234 | 200 | 151 | 1.5 | 0.275 | 35 | ||||

SMD019019-44 | 12 | 186 | 200 | 120 | 1.5 | 0.345 | 44 | ||||

SMD019019-62 | 12 | 132 | 250 | 85 | 1.6 | 0.426 | 68 | 1.6 | 2 | 62 | 37 |

SMD019019-83 | 12 | 99 | 250 | 64 | 1.6 | 0.57 | 83 | ||||

SMD019019-103 | 12 | 80 | 250 | 51 | 1.6 | 0.707 | 103 | ||||

SMD019019-111 | 12 | 74 | 250 | 48 | 1.6 | 0.762 | 111 | ||||

SMD019019-138 | 12 | 59 | 250 | 38 | 1.6 | 0.948 | 138 | ||||

SMD019019-150 | 12 | 55 | 250 | 35 | 1.6 | 1.03 | 150 | ||||

SMD019019-172 | 12 | 48 | 250 | 31 | 1.6 | 1.181 | 172 | ||||

SMD019019-186 | 12 | 44 | 250 | 28 | 1.6 | 1.277 | 186 | ||||

SMD019019-231 | 12 | 35 | 250 | 23 | 1.6 | 1.586 | 231 | ||||

SMD019019-243 | 12 | 34 | 250 | 22 | 1.6 | 1.6 | 243 | ||||

SMD019019-326 | 12 | 25 | 300 | 16 | 1.7 | 2.5 | 72 | 2 | 2.5 | 326 | 41 |

SMD019019-406 | 12 | 20 | 300 | 13 | 1.7 | 2.5 | 406 | ||||

SMD019019-439 | 12 | 19 | 300 | 12 | 1.7 | 2.5 | 439 | ||||

SMD019019-546 | 12 | 15 | 300 | 10 | 1.7 | 2.5 | 546 | ||||

SMD019019-590 | 12 | 14 | 300 | 9 | 1.7 | 2.5 | 590 | ||||

SMD019019-679 | 12 | 12 | 300 | 8 | 1.7 | 2.5 | 679 | ||||

SMD019019-734 | 12 | 11 | 300 | 7 | 1.7 | 2.5 | 734 | ||||

SMD019019-794 | 12 | 10 | 300 | 7 | 1.7 | 2.5 | 794 | ||||

SMD019019-913 | 12 | 9 | 300 | 6 | 1.7 | 2.5 | 913 | ||||

SMD019019-987 | 12 | 8 | 300 | 5 | 1.7 | 2.5 | 987 | ||||

SMD019019-1135 | 12 | 7 | 300 | 5 | 1.7 | 2.5 | 1135 | ||||

SMD019019-1227 | 12 | 7 | 300 | 4 | 1.7 | 2.5 | 1227 | ||||

SMD019019-1526 | 12 | 5 | 300 | 3 | 1.7 | 2.5 | 1526 | ||||

Application

Application scenario display: Widely used in industrial production, robotics, consumer electronics, smart medical, mobile travel and other intelligent fields

Service

Dedicated service, along the way

Warranty worry-free, extended repair, often return to promote optimization, peace of mind choice, all in control.

Before the purchase of professional consultants rapid response, accurate recommendation products;

Purchase logistics is efficient, specially-assigned to ensure delivery;

After the purchase 7×24 hours customer service answer questions, engineers at any time to save the "machine";

After-sale guarantee

After-sales service: We provide comprehensive after-sales technical support, if you encounter any problems in the process of use, the professional after-sales engineer team will respond quickly, through telephone, mail or remote assistance, to provide you with detailed solutions. We also provide regular return visits to our products to understand how they are used and to collect your feedback in order to continuously optimize our products and services. In addition, in strict accordance with the quality assurance policy, we provide free repair or replacement services for products with quality problems during the warranty period, so that you have no worries.